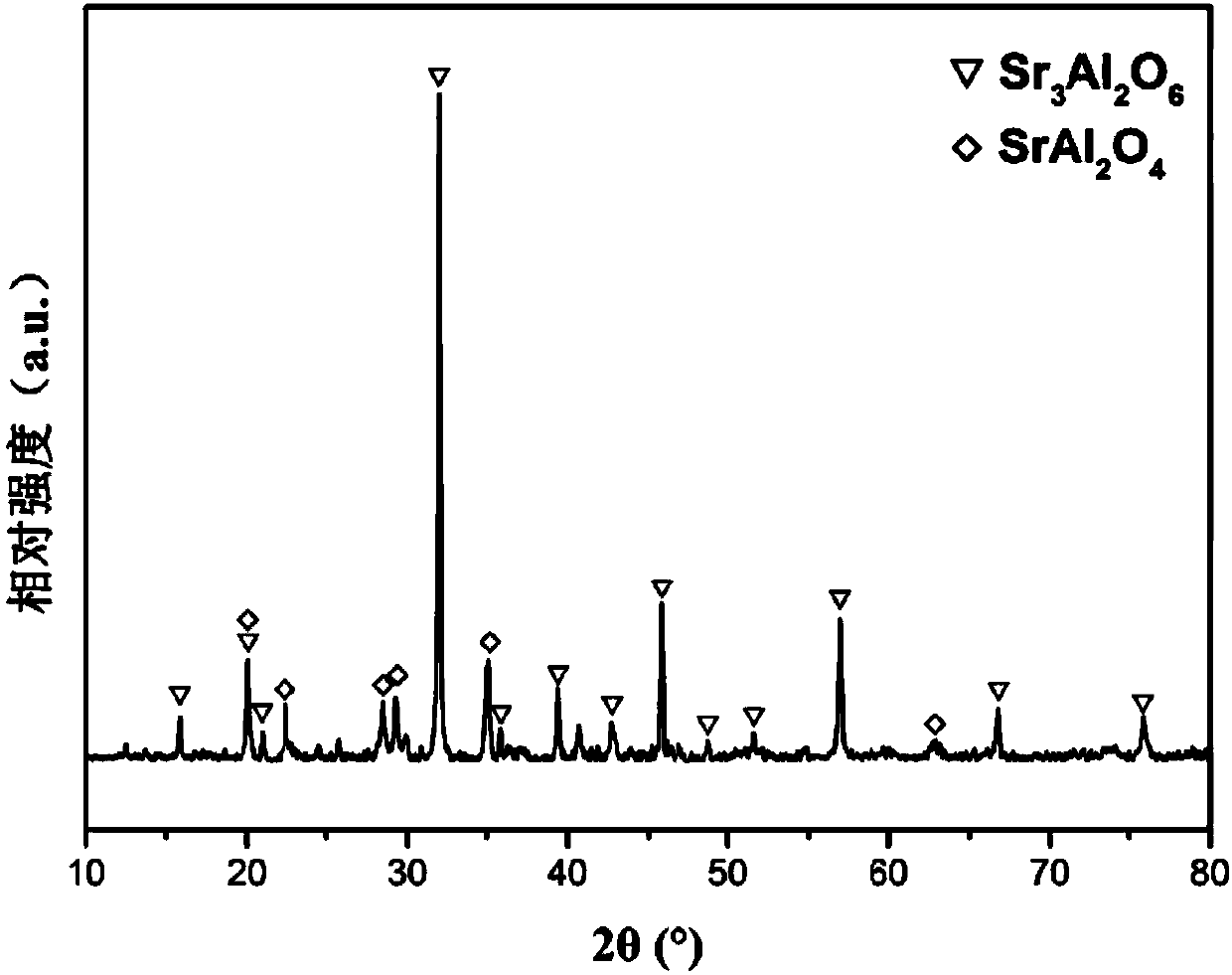

Transparent Sr3Al2O6-SrAl2O4 glass ceramic and preparation method thereof

A glass-ceramic, transparent technology, applied in the field of optical functional materials, can solve the problem of few reports in the field of ceramic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Raw material SrCO 3 with Al 2 o 3 The stoichiometric ratio of [x:(100-x), x=66.7] is used for weighing, mixing evenly and compacting. The compacted sample is calcined at 1400°C for 6 hours in a muffle furnace; the sintered block is then broken into diameters 3-5 mm blocks.

[0028] with CO 2 The pneumatic levitation device of the laser performs vitrification, puts the broken block into the inverted conical cavity, blows oxygen at the bottom, and the laser power reaches the full load power (150W), the block sample is completely molten, and the spherical sample rotates stably. The laser was turned off, and the sample was cooled at a cooling rate of 1000 °C / min to obtain a spherical glass sample.

[0029] The spherical glass sample was crushed into powder and placed in a graphite mold (inner diameter 20mm), and carbon paper was used to block between the mold and the powder. A spark plasma sintering furnace is used for sintering. The sintering parameters are: axial pre...

Embodiment 2

[0033] Raw material SrCO 3 with Al 2 o 3 The stoichiometric ratio of [x:(100-x), x=62] is used for weighing, mixing evenly and compacting. The compacted sample is calcined at 1200°C for 8 hours in a muffle furnace; the sintered block is then broken into diameters 3-5 mm blocks.

[0034] with CO 2 The pneumatic levitation device of the laser performs vitrification, puts the broken block into the inverted conical cavity, blows oxygen at the bottom, and the laser power reaches the full load power (150W), the block sample is completely molten, and the spherical sample rotates stably. The laser was turned off, and the sample was cooled at a cooling rate of 1000 °C / min to obtain a spherical glass sample.

[0035] The spherical glass sample was crushed into powder and placed in a graphite mold (inner diameter 20mm), and carbon paper was used to block between the mold and the powder. A spark plasma sintering furnace is used for sintering. The sintering parameters are: axial press...

Embodiment 3

[0037] Raw material SrCO 3 with Al 2 o 3 The stoichiometric ratio of [x:(100-x), x=65] is used for weighing, mixing evenly and compacting. The compacted sample is calcined at 1400°C for 4 hours in a muffle furnace; the sintered block is then broken into diameters 3-5 mm blocks.

[0038] with CO 2 The pneumatic levitation device of the laser performs vitrification, puts the broken block into the inverted conical cavity, blows oxygen at the bottom, increases the laser power to 100W, and the block sample is completely in a molten state. After the spherical sample rotates stably, turn it down. Laser power, rapid cooling, to obtain spherical glass samples.

[0039] The spherical glass sample was crushed into powder and placed in a graphite mold (inner diameter 20mm), and carbon paper was used to block between the mold and the powder. A spark plasma sintering furnace is used for sintering, the sintering parameters are: axial pressure 45MPa, end point temperature 880°C, heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com