A method for extracting quercetin and isoquercitrin from hypericum ascyron L.

A technology for isoquercitrin and Eclipta chinensis is applied in the field of extracting quercetin and isoquercitrin, and can solve the problems of low solubility, complicated operation, oil loss of aromatic compounds and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method for extracting quercetin and isoquercitrin from Eclipta chinensis specifically comprises the following steps:

[0026] 1) Clean the red eclipta, dry, pulverize with a pulverizer, and pass through a 20-mesh sieve;

[0027] 2) Subcritical water extraction: place the processed raw materials in an extraction kettle, add hydroxyethyl cellulose equivalent to 0.001 parts by weight of the raw materials, inject deoxygenated deionized water into the kettle at a flow rate of less than 10mL / min, and extract at a temperature of 185-200°C, pressure 8-10Mpa, extraction time 0.5h, extract the red eclipta, the extraction is completed, the pressure is released, the extract flows into the collection tank and cooled to room temperature, and the extract is obtained;

[0028] 3) Purification: Concentrate the extracts obtained in step 2) respectively, control the temperature to ≤50°C, control the vacuum at -0.08±0.01MPa, concentrate to 0.95-1.05g / ml, and perform column chromatograp...

Embodiment 2

[0030] The method for extracting quercetin and isoquercitrin from Eclipta chinensis specifically comprises the following steps:

[0031] 1) Clean the red eclipta, dry, pulverize with a pulverizer, and pass through a 40-mesh sieve;

[0032]2) Subcritical water extraction: place the processed raw materials in an extraction kettle, add hydroxyethyl cellulose equivalent to 0.001 parts by weight of the raw materials, inject deoxygenated deionized water into the kettle at a flow rate of less than 10mL / min, and extract at a temperature of 170-200°C, pressure 8-10Mpa, extraction time 0.5-1.0h, extract the red eclipta, after the extraction is completed, release the pressure, and collect two parts at 170-185°C and 185-200°C under 8-10Mpa respectively Extraction, take the liquid and flow into the collection tank to cool to room temperature;

[0033] 3) Purification: Concentrate the extract obtained in step 2) respectively, control the temperature to ≤50°C, control the vacuum at -0.08±0....

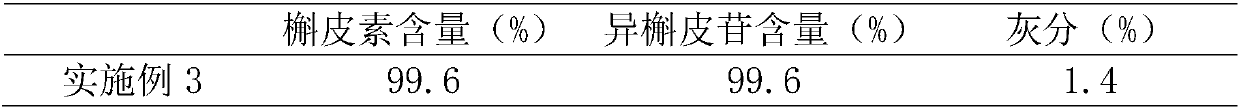

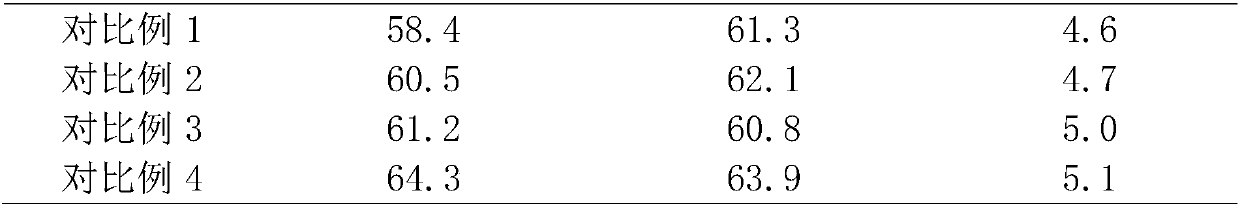

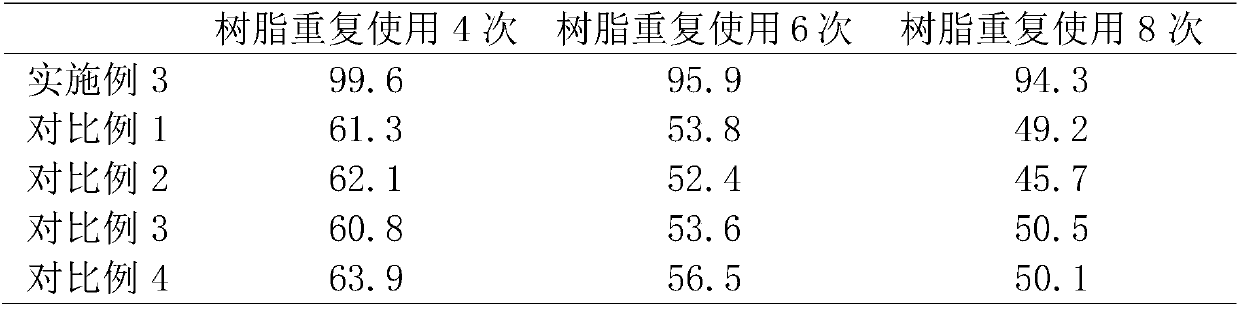

Embodiment 3

[0035] The method for extracting quercetin and isoquercitrin from Eclipta chinensis specifically comprises the following steps:

[0036] 1) Clean Eclipta chinensis, dry, pulverize with a pulverizer, and pass through an 80-mesh sieve;

[0037] 2) Subcritical water extraction: place the processed raw materials in an extraction kettle, add hydroxyethyl cellulose equivalent to 0.001 parts by weight of the raw materials, inject deoxygenated deionized water into the kettle at a flow rate of less than 10mL / min, and extract at a temperature of 170-200°C, pressure 8-10Mpa, extraction time 0.5-1.0h, extract the red eclipta, after the extraction is completed, release the pressure, and collect two parts at 170-185°C and 185-200°C under 8-10Mpa respectively Extraction, take the liquid and flow into the collection tank to cool to room temperature;

[0038] 3) Purification: Concentrate the extract obtained in step 2) respectively, control the temperature to ≤50°C, control the vacuum at -0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com