Method for extracting lignin from fibrous ethanol fermentation residue as raw material and coproducing phosphorus-potassium compound fertilizer

A technology of fermentation residue and fiber ethanol, which is applied in fiber raw material treatment, fertilizer mixture, fertilization equipment, etc., to achieve the effect of improving economy, reducing production cost and improving sustainable cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

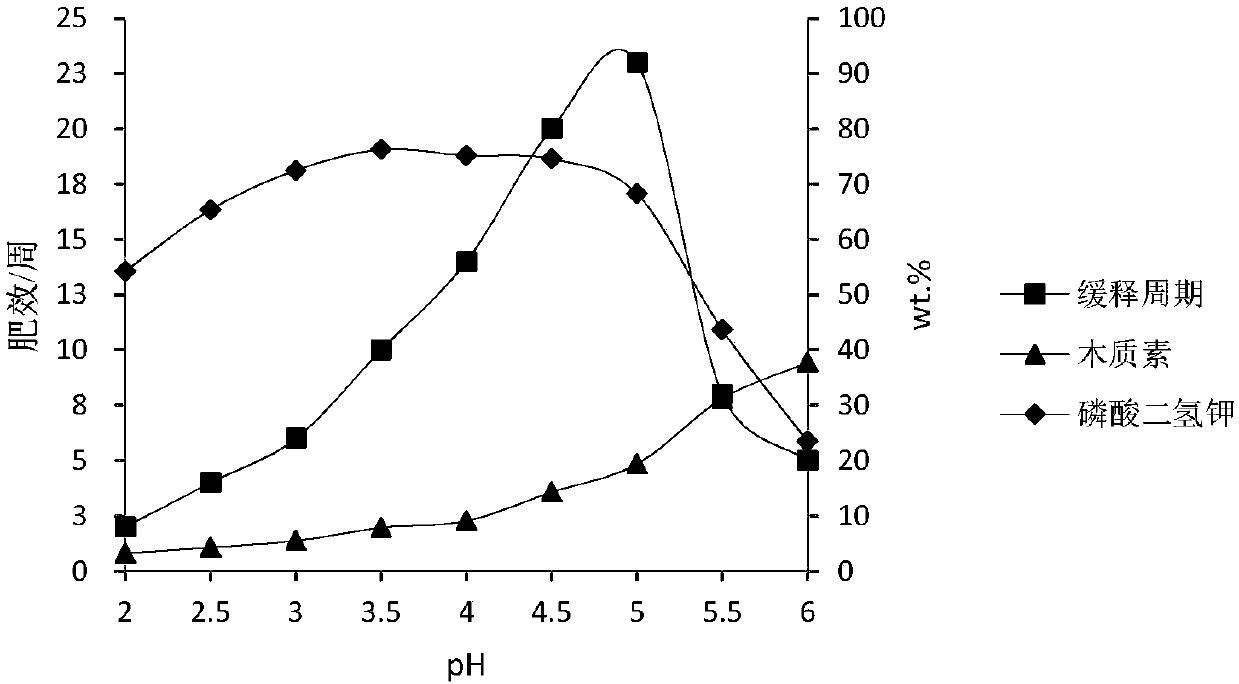

[0024] Get 1kg of corn stalk fiber ethanol fermentation residue and put it into an 8L reaction tank, and add 2.16wt.% KOH aqueous solution 5.799L thereinto to adjust the final alkali concentration of the reaction solution (referring to the water and KOH in the corn stalk fiber ethanol fermentation residue The alkali concentration in the mixed solution obtained by mixing the aqueous solution, the same below) is 2wt.%, and the final solid-liquid ratio (referring to the solid-liquid ratio of the absolute dry substance in the corn stalk fiber ethanol fermentation residue and the mixed solution, the same below) is 1kg: 12L, and then extract lignin by alkaline method at 70°C for 3h. After the reaction, the screw press was used to separate the solid and liquid, and the mass ratio of HM straw decomposing and solid phase residue was 0.1g:1kg, and the composting treatment was carried out for 15 days, so as to realize the reuse of biomass in the field, and the filtrate was lignin solutio...

Embodiment 2

[0029] Take 1kg of corn stalk fiber ethanol fermentation residue and put it into an 8L reaction tank, and add 4.753L of 3.30wt.% KOH aqueous solution to it to adjust the final alkali concentration of the reaction solution to 3wt.%, and the final solid-liquid ratio to 1kg:10L , and then lignin was extracted by alkaline method at 80°C for 2.5h. After the reaction, the screw press was used to separate the solid and liquid, and the mass ratio of HM straw decomposing and solid phase residue was 0.1g:1kg, and the composting treatment was carried out for 15 days, so as to realize the reuse of biomass in the field, and the filtrate was lignin solution.

[0030] Slowly add 85wt.% industrial phosphoric acid to the lignin solution to adjust its pH to 4, during which the stirring speed is set to 500rpm. The mixture is then injected into a plate and frame filter device for solid-liquid separation again. The solid phase is washed and dried to obtain lignin solid powder; the liquid phase i...

Embodiment 3

[0033] Take 1kg of corn stalk fiber ethanol fermentation residue and put it into an 8L reaction tank, and add 4.230L of 4.45wt.% KOH aqueous solution to it to adjust the final alkali concentration of the reaction solution to 4wt.%, and the final solid-liquid ratio to 1kg:9L , and then lignin was extracted by alkaline method at 90° C. for 1 h. After the reaction, use a screw press for solid-liquid separation, and mix and compost the HM straw for 15 days at a mass ratio of 0.1 g: 1 kg to solid phase residue, so as to realize the reuse of biomass in the field. The liquid is lignin solution.

[0034] Slowly add 85wt.% industrial phosphoric acid to the lignin solution to adjust its pH to 4, during which the stirring speed is set to 500rpm. The mixture is then injected into a plate and frame filter device for solid-liquid separation again. The solid phase is washed and dried to obtain lignin solid powder; the liquid phase is spray-dried, and the final product can be used as a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com