Preparation method of stable and white-light LED

A white light and stable technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor stability of perovskite quantum dots, achieve the effects of improving poor stability, avoiding agglomeration, and increasing fluorescence quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

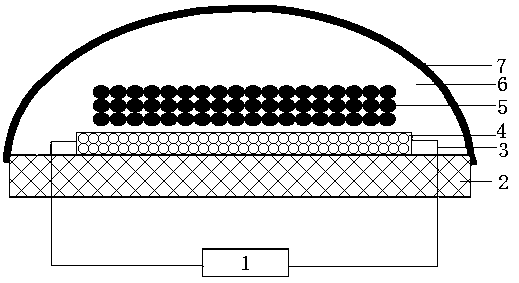

Image

Examples

Embodiment 1

[0018] Perovskite CsPb(Br / Cl) coated with mesoporous silica with luminous peak wavelength of 480nm 3 Quantum dots, 530nm green mesoporous silica-wrapped perovskite CsPbBr 3 Quantum dots and 630nm red mesoporous silica-wrapped perovskite CsPb(Br / I) 3 Quantum dots are used as the light-emitting layer after mixing, and the ultraviolet chip is used as the excitation light source to obtain a stable white LED.

[0019] The preparation scheme of stable white LED based on mesoporous silica-wrapped perovskite quantum dots is as follows:

[0020] Chemical material: brilliant carbonate (99.9%, CsCO 3 ), oleic acid (90%, OA), octadecene (90%, 1-ODE), lead bromide (PbBr 2 , 99.0%), lead iodide (PbI 2 , 99.0%), lead chloride (PbCl 2 ), n-octylphosphine (TOP, 90%) n-hexane (99.5%) and toluene (99.5%), oleylamine (90.0%, OAM), mesoporous silica (pore size 17.25nm, 14.38nm and 6.08nm The three types), Dow Corning OE6550 potting glue.

[0021] The first step: select the ultraviolet (LED)...

Embodiment 2

[0034] The steps are the same as in the specific example 1, except that the blue-light mesoporous silicon dioxide is used to wrap the perovskite CsPb(Br / Cl) with a peak wavelength of 490 nm. 3 Quantum dots, 550nm green mesoporous silica-wrapped perovskite CsPbBr 3 Quantum dots and 640nm red mesoporous silica-wrapped perovskite CsPb(Br / I) 3 Quantum dots, and "Instant injection of 0.6ml cesium oleate precursor" in the second step "Preparation of Perovskite Quantum Dots".

Embodiment 3

[0036] The steps are the same as in the specific example 1, except that in the third step, the perovskite red light ore quantum dots, green light quantum dots and blue light quantum dots wrapped in mesoporous silica are mixed according to the mass ratio: 3:2:8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com