Method for preparing mango powder

A mango powder and mango technology, which is applied in the field of food processing, can solve the problems of mango color, aroma and taste fade, drying fire power, difficulty in time control, loss of nutrients, etc. Good, growth-inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

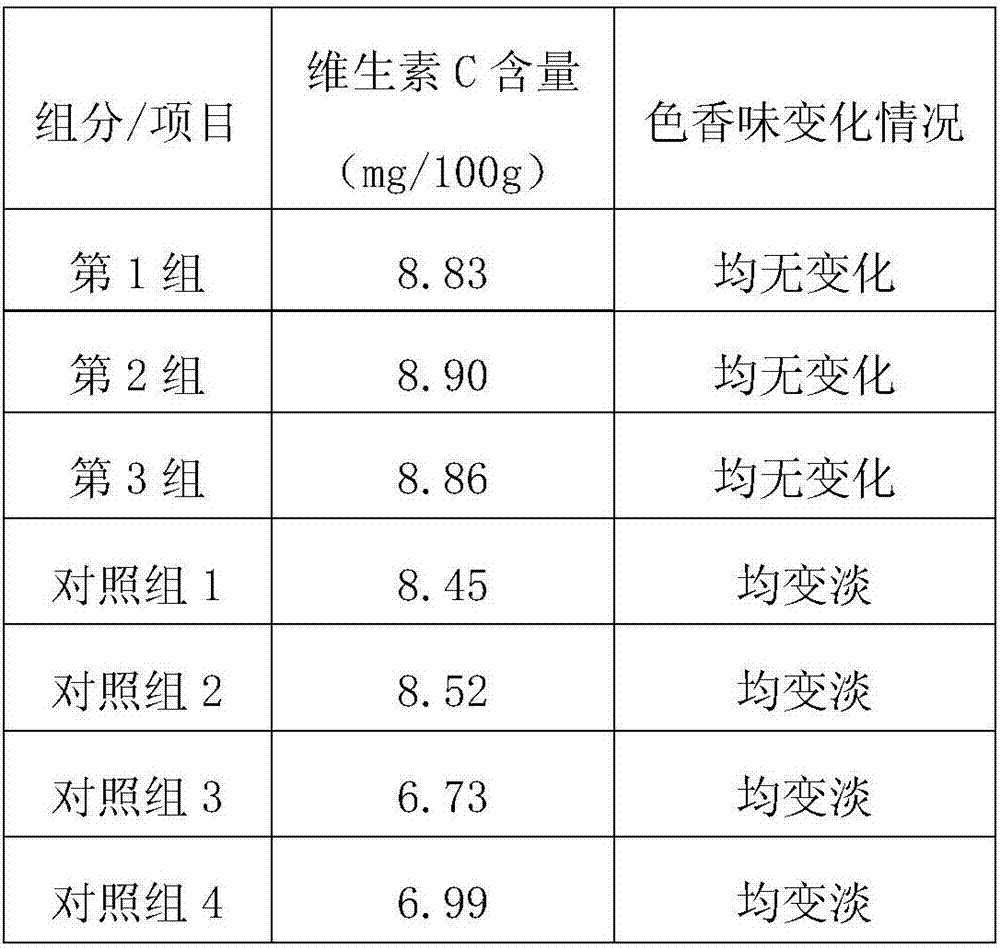

Examples

Embodiment 1

[0025] A kind of preparation method of mango powder of the present embodiment, comprises the following steps:

[0026] (1) Raw material selection: choose fresh and ripe mangoes without rot and no pests and diseases, rinse them repeatedly in running water until the silt and sundries on the skin are washed, drain the water, and set aside;

[0027] (2) Blanching and peeling: Pour the washed mangoes into hot water at 85°C for 1 minute, cool, peel, remove cores, cut into dices, and set aside;

[0028] (3) beating: the above-mentioned diced fruit, 0.05% vitamin C solution and catechin are put into a beater together to make a pulp, and the weight ratio of the diced fruit, 0.05 vitamin C solution and catechin is 1: 2:0.02, filter with gauze, get the juice, and set aside;

[0029] (4) Blending and homogenization: Add 0.4% of citric acid, 0.5% of xanthan gum, 15% of cornstarch and 10% of malt paste according to the weight percentage of the additives, and dissolve them in warm water at ...

Embodiment 2

[0034] A kind of preparation method of mango powder of the present embodiment, comprises the following steps:

[0035] (1) Raw material selection: choose fresh and ripe mangoes without rot and no pests and diseases, rinse them repeatedly in running water until the silt and sundries on the skin are washed, drain the water, and set aside;

[0036] (2) Blanching and peeling: Pour the washed mangoes into hot water at 100°C for 2 minutes, cool, peel, remove pits, cut into cubes, and set aside;

[0037] (3) beating: the above-mentioned diced fruit, 0.08% vitamin C solution and catechin are put into a beater together to make a pulp, and the weight ratio of the diced fruit, 0.08% vitamin C solution and catechin is 1 :4:0.05, filter through gauze, get the juice, and set aside;

[0038] (4) Blending and homogenization: Add 0.6% of citric acid, 1.5% of xanthan gum, 25% of cornstarch and 20% of malt paste according to the weight percentage of additives, and dissolve them in warm water at...

Embodiment 3

[0043] A kind of preparation method of mango powder of the present embodiment comprises the following steps:

[0044] (1) Raw material selection: choose fresh and ripe mangoes without rot and no pests and diseases, rinse them repeatedly in running water until the silt and sundries on the skin are washed, drain the water, and set aside;

[0045] (2) Blanching and peeling: Pour the washed mangoes into hot water at 90°C for 1.5 minutes, cool, peel, remove pits, cut into cubes, and set aside;

[0046] (3) beating: the above-mentioned diced fruit, 0.06% vitamin C solution and catechin are put into a beater together to make a pulp, and the weight ratio of the diced fruit, 0.06% vitamin C solution and catechin is 1 :3:0.04, filter through gauze, get the juice, and set aside;

[0047] (4) Blending and homogenization: Add 0.5% citric acid, 1% xanthan gum, 20% cornstarch and 15% malt paste according to the weight percentage of additives. After the liquid is mixed, the mixed solution is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com