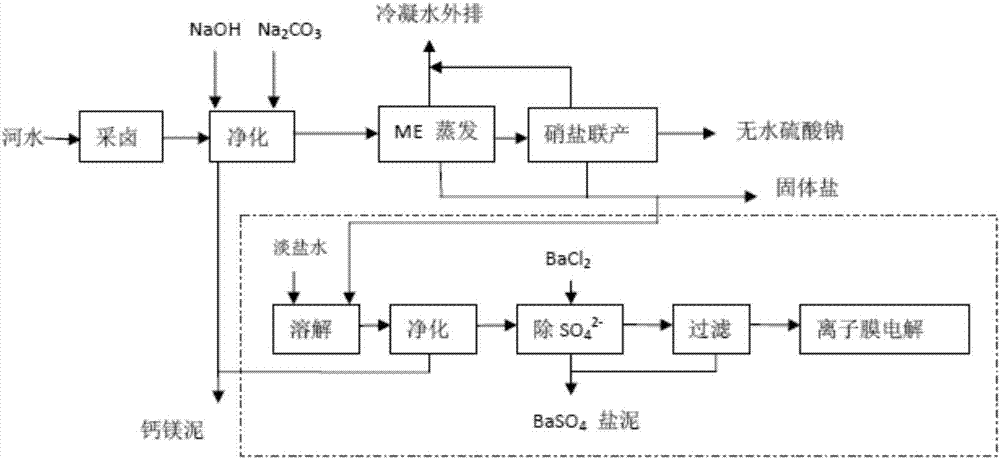

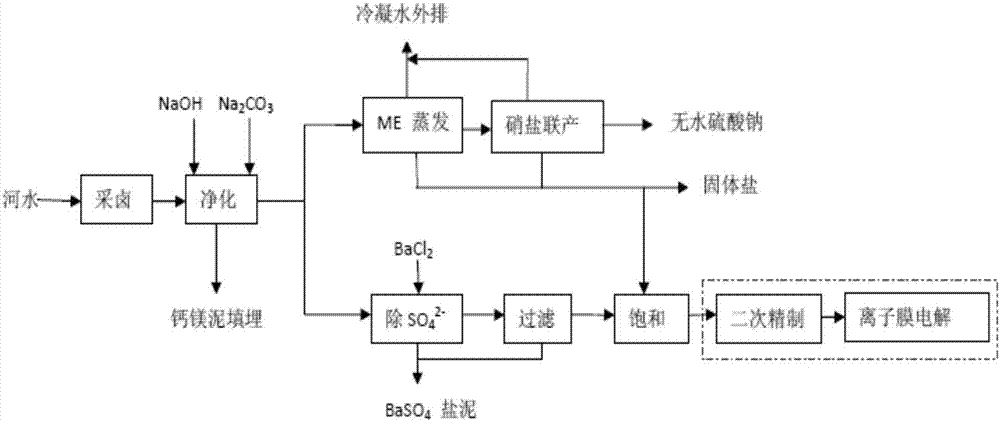

Clean and energy-saving type production and salt preparation process

An energy-saving and technological technology, applied in the field of clean and energy-saving production of salt-making technology, can solve the problems of large environmental pollution, high energy consumption of the salt-making process, low resource utilization rate, etc., and achieve the effect of improved purity and obvious quality advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

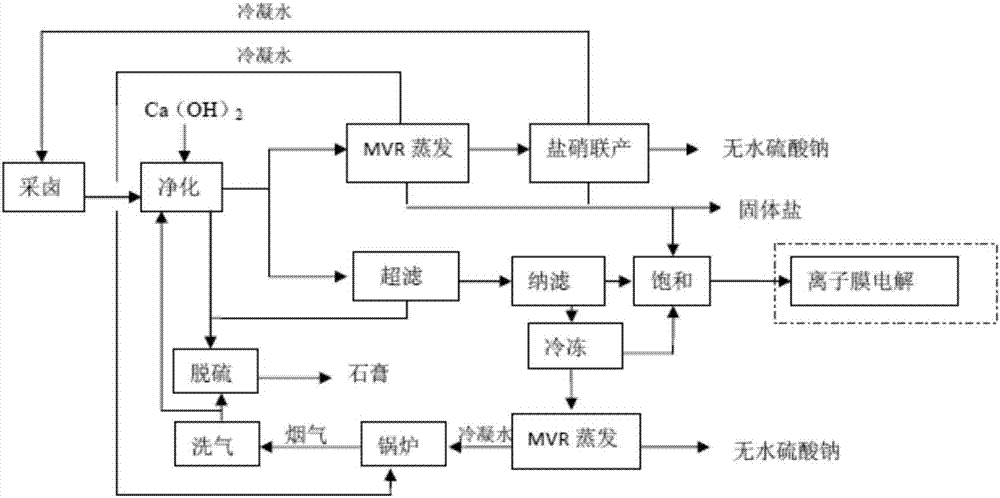

Embodiment 1

[0040] For NaCl 300g / L, Na 2 SO 4 12g / L and contains CaSO 4 , MgSO 4 Add lime milk (Ca(OH) in lime milk 2 80g / L, control the molar ratio of calcium ions and sulfate ions in brine to 1.05:1), and then use lime flue gas (CO 2 The volume concentration is 15%, SO 2 Volume concentration is 1%, and all the other are nitrogen, oxygen, water vapor) process this bittern, when bittern pH value reaches 10, stop logical lime flue gas, to precipitate calcium ion and magnesium ion in former bittern, the bittern after reaction After being filtered by a coarse filter, it is pumped into a ceramic ultrafiltration membrane filter device to remove calcium and magnesium;

[0041] The resulting clarified liquid (mainly containing sodium ions, chloride ions and sulfate ions) is all put into the mechanical thermal compression (MVR) evaporation crystallization technology to prepare solid salt: the clarified liquid is heated by a multi-stage preheater and then enters the autoclave in turn , ener...

Embodiment 2

[0059] For NaCl 300g / L, Na 2 SO 4 12g / L and contains CaSO 4 , MgSO 4 Add lime milk (Ca(OH) in lime milk 2 80g / L, control the molar ratio of calcium ions and sulfate ions in the brine to 1.05:1), then use the lime flue gas that has passed through the desulfurization device to treat the brine, and stop the lime flue gas when the pH value of the brine reaches 10 , to precipitate calcium ions and magnesium ions in the original brine, filter the reacted brine through a coarse filter, and then pump it into a ceramic ultrafiltration membrane filter device to remove calcium and magnesium;

[0060] The brine clarified liquid after the above purification is divided into two paths, one goes into the storage tank for standby, and the other is mixed with light brine. Sodium sulfate product is prepared by mechanically compressing and evaporating the enriched sodium sulfate after filtration; after the membrane, the low nitric water is added with alkali, mixed with the brine in the stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com