Method for casting machine tool body from steel-making tailings

A technology of tailings and machine tools, which is applied in the field of using steelmaking tailings to cast machine tool beds, can solve the problem that the utilization rate of steelmaking tailings is less than 40%, so as to improve the stability of machine tools, improve precision and product yield, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for casting a bed of a machine tool using steelmaking tailings, comprising the following steps:

[0028] 1. Put the recovered steelmaking tailings into the crushing machine for crushing, and then crush them through the crushing equipment to obtain irregular tailings particles with a size of 3-15mm for use;

[0029] 2. The recovered iron sand is crushed and ball milled to make iron sand powder for later use;

[0030] Three, get 7 parts of epoxy resin by weight and add epoxy resin diluent and mix into solution, add 2.1 parts by weight of anhydride curing agent, add 1 part of bismuth and mix and stir to make the mixed solution for subsequent use;

[0031] 4. Take 65 parts by weight of steelmaking tailings, 5 parts of iron sand powder, 10 parts of silica powder, 5 parts of quartz sand, and 5 parts of quartz powder into the mixer, mix and stir evenly, and then add the mixed solution prepared in step 3 , stir evenly again, finally add 1 part of carbon fiber and 1 pa...

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1, the difference is:

[0048] 3. Get 10 parts of epoxy resin by weight and add epoxy resin diluent to mix into a solution, add 3 parts of anhydride curing agent by weight, add 1 part of antimony and mix and stir to make a mixed solution for subsequent use;

[0049] Four, get 75 parts by weight of steelmaking tailings, 10 parts of iron sand powder, 5 parts of silica powder, 10 parts of quartz sand, 10 parts of quartz powder are added in the mixer, mix and stir evenly, then add the mixed solution that step 3 makes, Stir again evenly, and finally add 1 part of carbon fiber and 1 part of basalt fiber, then seal and vacuum the mixer, and stir again for 5-10 minutes at a vacuum degree below 0.001Mpa to obtain a mixed material;

[0050] The remaining steps are consistent with Embodiment 1.

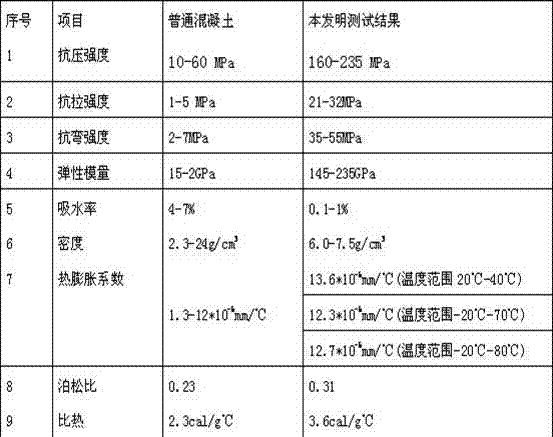

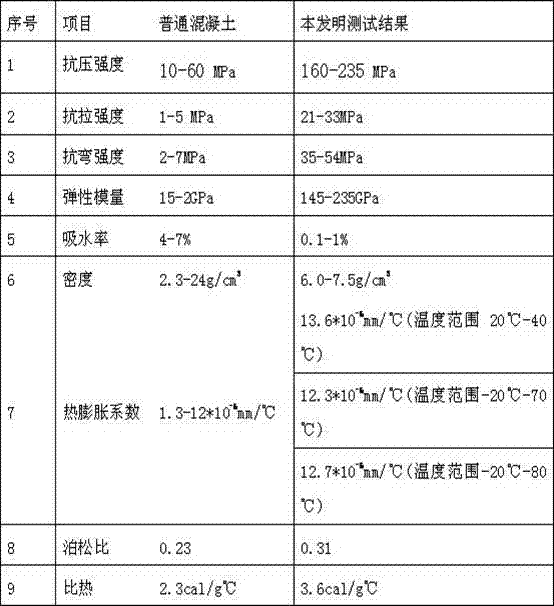

[0051] In this embodiment, the multi-batch machine tool beds casted according to the above method are tested, and the results are as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com