Corrosion resistant grafted polymer, preparation method of grafted polymer and plastic bottle which is used for storing high-corrosion pesticide and made by using grafted polymer as raw material

A grafted polymer, corrosion-resistant technology, applied in the field of plastic organic materials, can solve problems such as high production costs, erosion, and danger, and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

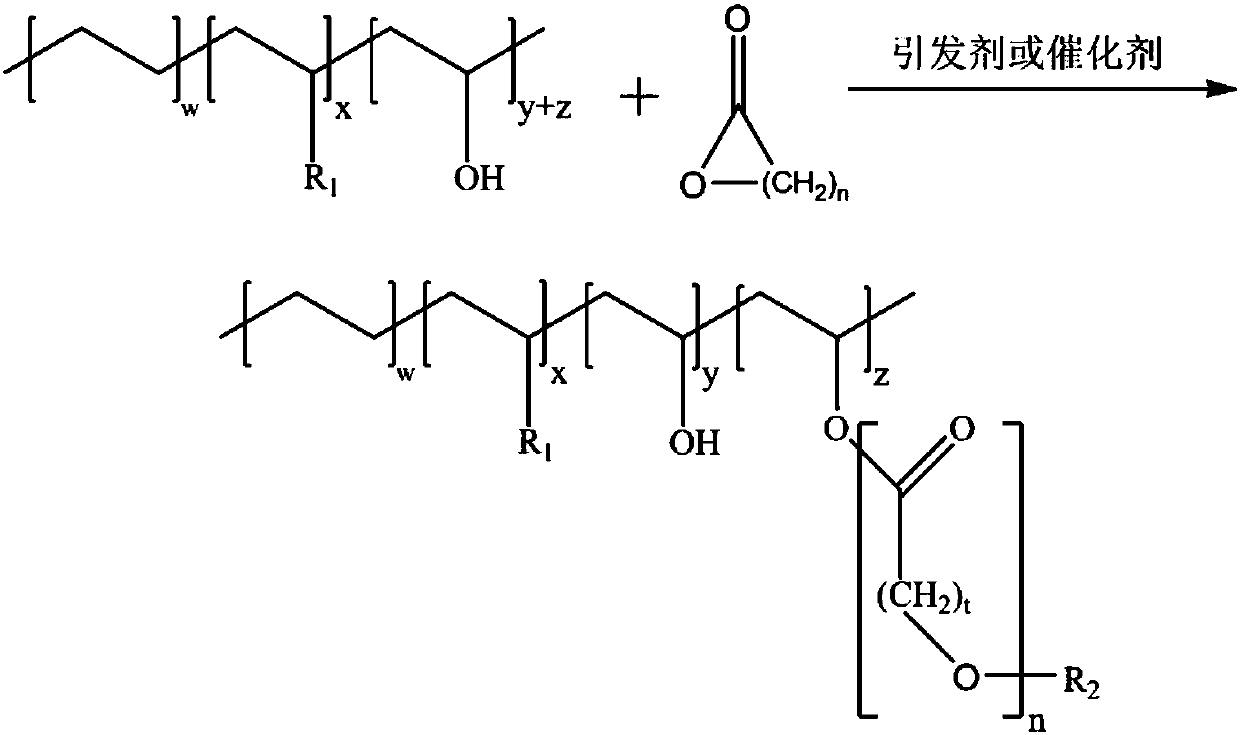

Method used

Image

Examples

Embodiment 1

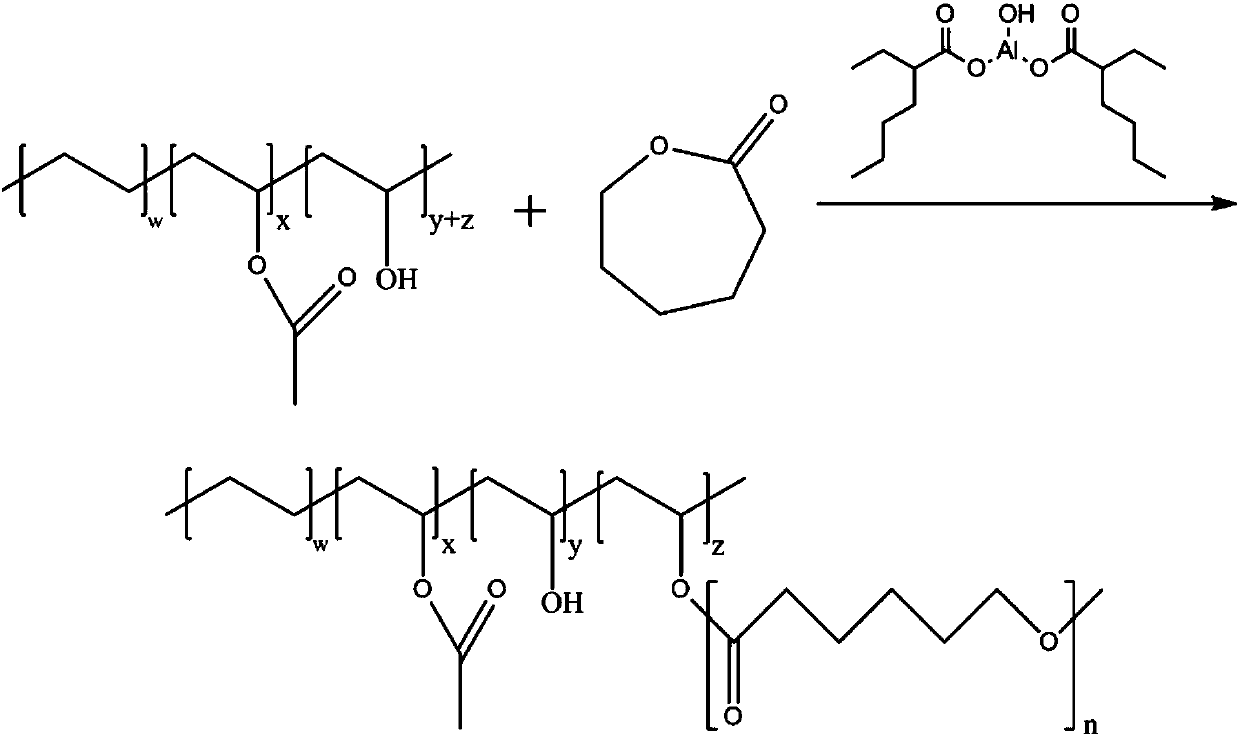

[0072] Preparation of ethylene / vinyl alcohol / vinyl acetate copolymer-graft-poly(ε-caprolactone). Graft polymers are formed by ring-opening polymerized lactones introduced on the hydroxyl functionality of ethylene / vinyl alcohol / vinyl acetate copolymers.

[0073] The specific preparation method is as follows: firstly, ethylene / vinyl alcohol / vinyl acetate copolymer is introduced into a reactor preheated to 205°C and stirred, and the ε-caprolactone monomer preheated to 175°C is placed in The ethylene / vinyl alcohol / vinyl acetate copolymer was introduced into the reactor immediately after stirring. Control the mass ratio of ethylene / vinyl alcohol / vinyl acetate copolymer to ε-caprolactone monomer to be 1.1:1, and obtain a uniform viscous mixture after 15-30 minutes. It has been determined that during the above process in this embodiment, when the mixed system melts, the set point temperature decreases from 205°C to 178°C. Then add the initiator into the mixing system at 178°C for d...

Embodiment 2

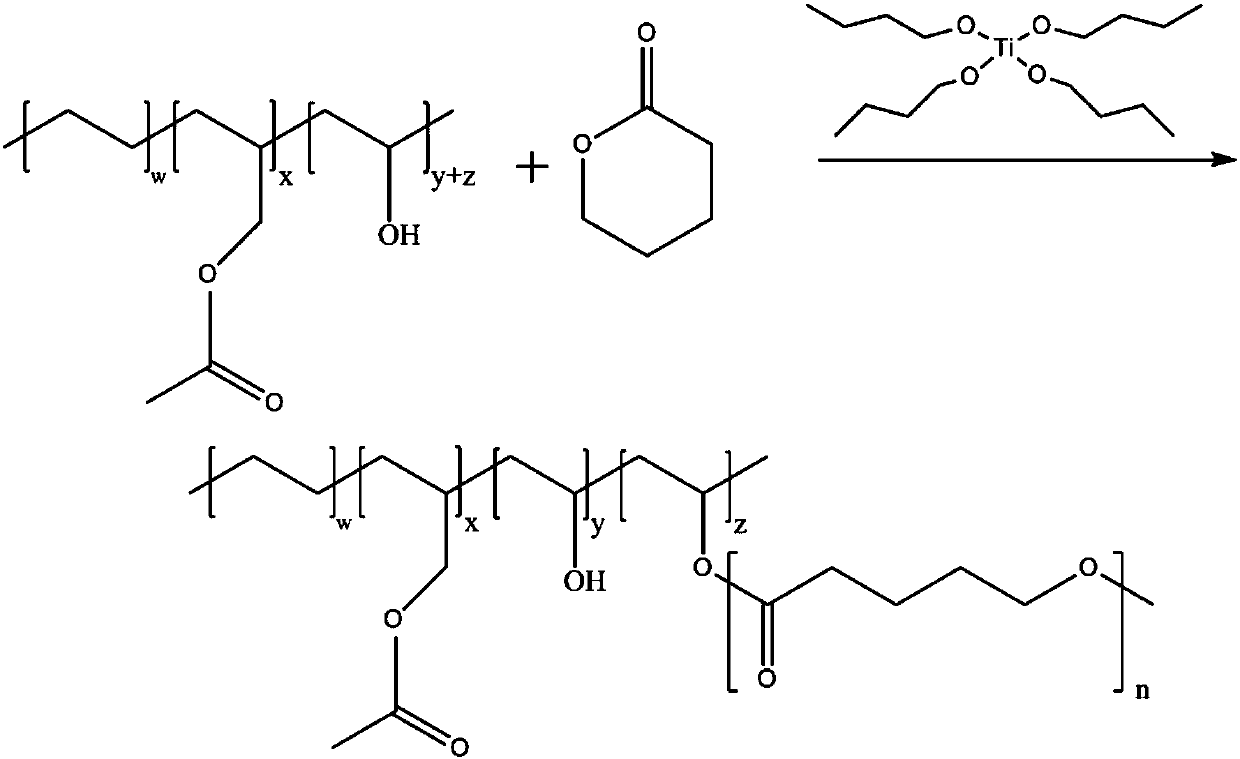

[0078] Preparation of ethylene / vinyl alcohol / ethyl acrylate copolymer-graft-poly(delta-valerolactone). The graft polymer was formed by introducing ring-opening polymerized delta-valerolactone on the hydroxyl functionality of an ethylene / vinyl alcohol / ethyl acrylate copolymer.

[0079] The same preparation method as in Example 1 was used.

[0080] In this embodiment, the ethylene monomer content in the ethylene / vinyl alcohol / ethyl acrylate copolymer is 39%. The formulation ratio used in this example is: 239 g of ethylene / vinyl alcohol / ethyl acrylate copolymer, 308 g of δ-valerolactone, and 21 g of dibutyltin dilaurate as the initiator. Analysis of the sample after 15 minutes of reaction showed a 100% conversion of the monomers and a measured average degree of polymerization equal to 3.5.

Embodiment 3

[0082] A plastic bottle for long-lasting storage of highly corrosive pesticides.

[0083] As shown in the figure, the bottle body of the plastic bottle that can store highly corrosive pesticides for a long time adopts a five-layer composite structure, which includes an inner layer 1, a high-efficiency barrier layer 2 and an outer layer 3 in order from the inside to the outside. The high-efficiency barrier layers 2 are connected by an adhesive layer 4, and the high-efficiency barrier layer 2 and the outer layer 3 are connected by an adhesive layer 5, wherein

[0084] The material of the high-efficiency barrier layer 2 is the graft polymer prepared in Example 1, the material of the inner layer 1 is high-density polyethylene, and the material of the outer layer 3 is metallocene linear low-density polyethylene, The material of the adhesive layer is an anhydride-modified ethylene-vinyl acetate copolymer.

[0085] The mouth of the bottle is sealed by an aluminum foil gasket, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com