Method of comprehensively extracting grease, proteins, aucubin, and eucommia ulmoides gum from eucommia seeds

A technique for comprehensive extraction of aucubin, applied in the fields of chemical industry and food, to achieve the effects of reducing emissions, high extraction yield, and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

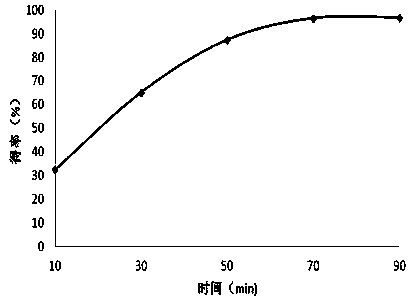

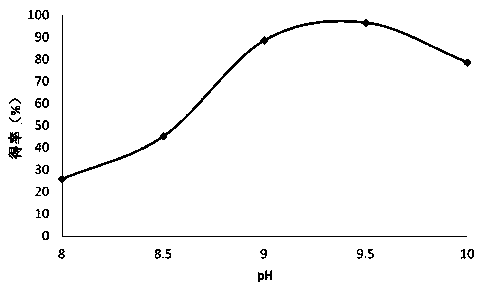

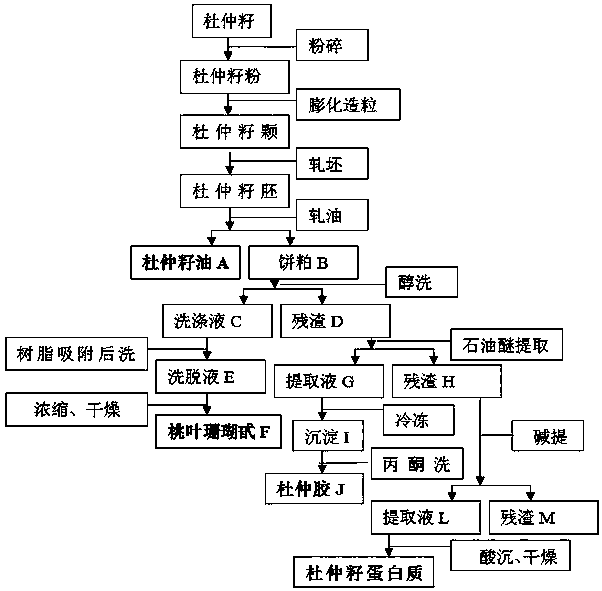

Method used

Image

Examples

Embodiment 1

[0027] A comprehensive extraction method for oil, protein, aucubin and eucommia gum in Eucommia ulmoides seeds, the steps are as follows:

[0028] (1) Using Eucommia ulmoides seeds as raw material, after crushing eucommia ulmoides seeds to 20 meshes, a twin-screw extruder is used for extrusion puffing and granulation. The extrusion temperature during granulation is 220°C, and the water content of the granules after extrusion is 5%;

[0029] (2) After granulation, use a roller press to slab to a thickness of less than 0.5mm, and then press at 60°C and 4.0MPa to obtain eucommia seed oil A and cake B;

[0030] (3) The cake B obtained after pressing is first washed with 100% ethanol as an alcohol washing solvent to obtain washing liquid C and residue D;

[0031] (4) Washing liquid C was adsorbed by macroporous resin T8 and then eluted with 3 times column volume of acetone to obtain eluent E. The eluent was concentrated in vacuum at 60°C and dried to obtain aucubin F; residue D was...

Embodiment 2

[0039] A comprehensive extraction method for oil, protein, aucubin and eucommia gum in Eucommia ulmoides seeds, the steps are as follows:

[0040] (1) Using Eucommia ulmoides seeds as raw material, after crushing eucommia ulmoides seeds to 60 meshes, extruding and puffing granulation with a twin-screw extrusion device, the extrusion temperature during granulation is 200°C, and the water content of the granules after extrusion is 7%;

[0041] (2) After granulation, use a roller press to slab to a thickness of less than 0.5mm, and then press at 70°C and 3.8MPa to obtain Eucommia seed oil A and cake B;

[0042] (3) The cake B obtained after pressing is first washed with 50-100% ethanol as an alcohol washing solvent to obtain washing liquid C and residue D;

[0043] (4) Washing solution C was adsorbed by macroporous resin T8 and eluted with 3 times column volume of acetone to obtain eluent E. The eluent was concentrated in vacuum at 40°C and dried to obtain aucubin F; residue D wa...

Embodiment 3

[0051] A method for comprehensively extracting oil, protein, aucubin and eucommia gum from Eucommia ulmoides seeds, the steps are as follows:

[0052] (1) Using Eucommia ulmoides seeds as raw material, after crushing eucommia ulmoides seeds to 20 meshes, a twin-screw extruder is used for extrusion puffing and granulation. The extrusion temperature during granulation is 50°C, and the water content of the granules after extrusion is 6%;

[0053](2) After granulation, use a roller press to roll the billet until the thickness is less than 1.0mm, and then press at 80°C and 3.5MPa to obtain Eucommia seed oil A and cake B;

[0054] (3) The cake B obtained after pressing is first washed with 100% ethanol as an alcohol washing solvent to obtain washing liquid C and residue D;

[0055] (4) Washing liquid C was adsorbed by macroporous resin T8 and then eluted with 3 times column volume of acetone to obtain eluent E. The eluent was concentrated in vacuum at 60°C and dried to obtain aucubi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com