High-conductivity copper alloy and preparation method thereof

A high conductivity, copper alloy technology, applied in the direction of metal/alloy conductors, etc., can solve the problems of increasing the difficulty of development, and achieve the effects of enhanced mechanical properties, good mechanical properties, and less element burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

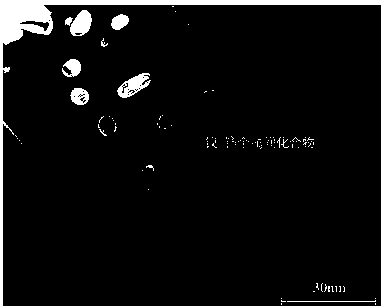

Image

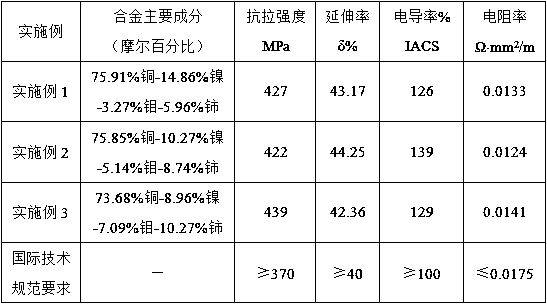

Examples

Embodiment 1

[0039] A preparation method of high-conductivity copper alloy, comprising the following steps:

[0040] S1. With an ingot weight of 20kg in total, prepare electrolytic copper, copper-molybdenum master alloy (molybdenum content of 40%), and nickel-cerium master alloy (cerium content of 30%) according to mole percentage, and prepare for smelting;

[0041] S2. Place the prepared electrolytic copper in a vacuum induction furnace, -2 The low vacuum state of MPa is filled with argon for protection, and the temperature is heated to 1600°C for melting, and the melting time is 127 minutes;

[0042] After the smelting is complete, add copper-molybdenum master alloy to the liquid electrolytic copper, and keep 1×10 -2 MPa low vacuum argon protection state, continue melting for 127min under the condition of raising the temperature to 1680°C;

[0043] Finally, add nickel-cerium master alloy to the liquid metal liquid, and keep 1×10 -2 MPa low-vacuum argon protection state, the temperatur...

Embodiment 2

[0048] A preparation method of high-conductivity copper alloy, comprising the following steps:

[0049] S1. Based on an ingot weight with a total mass of 15kg, electrolytic copper, copper-molybdenum master alloy (45% molybdenum content), and nickel-cerium master alloy (35% cerium content) are prepared for melting according to mole percentage;

[0050] S2. Place the prepared electrolytic copper in a vacuum induction furnace, -3The low vacuum state of MPa is filled with argon for protection, and the temperature is heated to 1520°C for melting, and the melting time is 90 minutes;

[0051] After the smelting is complete, add copper-molybdenum master alloy to the liquid electrolytic copper, and keep 5×10 -3 In the low vacuum argon protection state of MPa, continue melting for 90 minutes under the condition of raising the temperature to 1660°C;

[0052] Finally, add nickel-cerium master alloy to the liquid metal liquid, and keep 5×10 -3 MPa low-vacuum argon protection state, the ...

Embodiment 3

[0057] A preparation method of high-conductivity copper alloy, comprising the following steps:

[0058] S1. With an ingot weight of 10kg in total mass, electrolytic copper, copper-molybdenum master alloy (40% molybdenum content), and nickel-cerium master alloy (30% cerium content) are prepared for melting according to mole percentage;

[0059] S2. Place the prepared electrolytic copper in a vacuum induction furnace, -3 The low vacuum state of MPa is filled with argon for protection, and the temperature is heated to 1480°C for melting, and the melting time is 63 minutes;

[0060] After the smelting is complete, add copper-molybdenum master alloy to the liquid electrolytic copper, and keep 1×10 -3 In the low vacuum argon protection state of MPa, continue melting for 63 minutes under the condition of raising the temperature to 1650°C;

[0061] Finally, add nickel-cerium master alloy to the liquid metal liquid, and keep 1×10 -3 MPa low vacuum argon protection state, the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com