A kind of high sulfur capacity zinc oxide fine desulfurizer and preparation method thereof

A technology of zinc oxide and fine desulfurization, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, etc. Wear and other problems, to achieve the effect of more active sites, increase the sulfur capacity, and increase the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

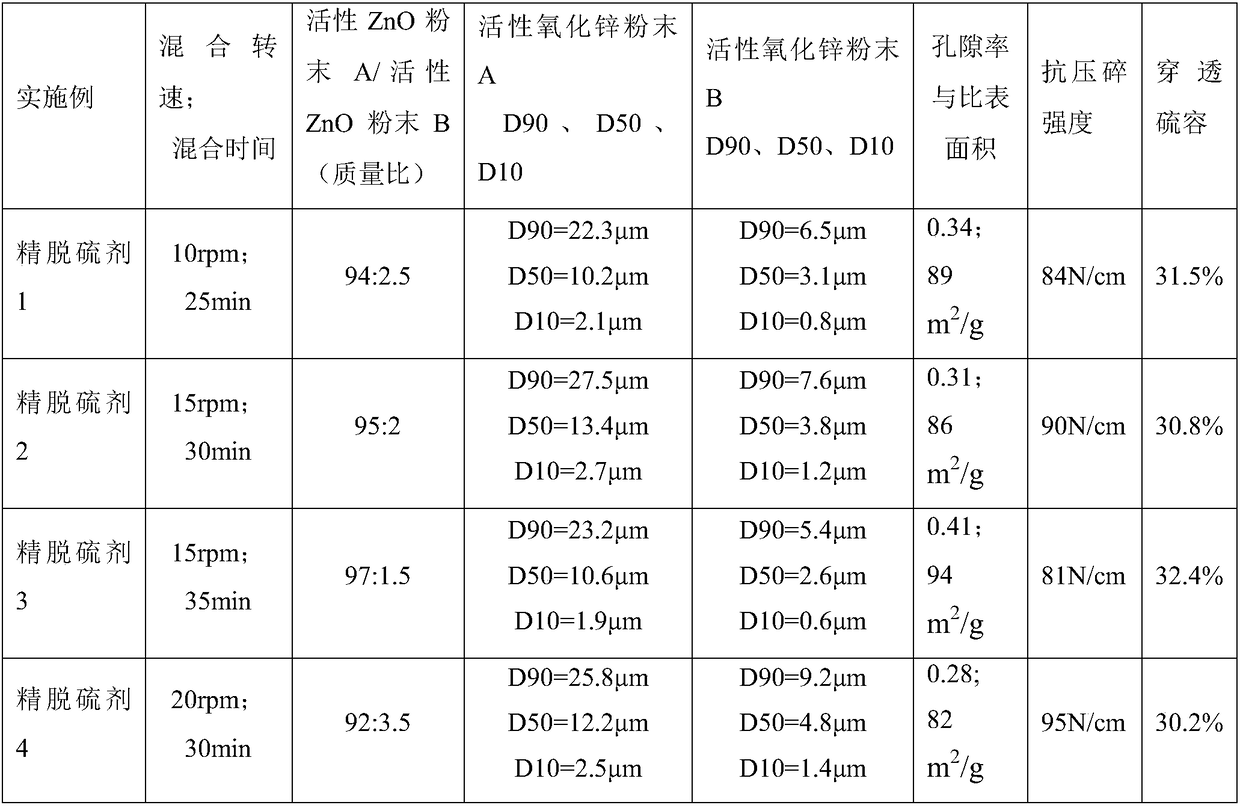

Examples

Embodiment 1

[0039] The preparation process of the fine desulfurizer in the present embodiment comprises the following steps:

[0040] S1: sieve commercially available zinc oxide through a vibrating sieve, and collect the raw material powder with a bulk density of 0.30kg / l after sieving for subsequent use; the raw material powder collected by the micropowder collection system (hereinafter referred to as the collected raw material powder) is shaken The sieve is sieved, and the raw material powder with a bulk density of 0.16kg / l after sieving is collected for use;

[0041] S2: 94 parts by weight of commercially available zinc oxide after sieving and 2.5 parts by weight of raw material powder collected for standby are added to the hopper mixer for mixing, the mixing speed is 10 rpm, and the mixing time is 25 minutes.

[0042] S3: adding the material after S2 mixing and kaolin to the kneader according to the weight ratio of 96.5:3.5, mixing, stirring and kneading at room temperature for 30 min...

Embodiment 2

[0047] The preparation process of the fine desulfurizer in the present embodiment comprises the following steps:

[0048] S1: sieve commercially available zinc oxide through a vibrating sieve, and collect the raw material powder with a bulk density of 0.38kg / l after sieving for subsequent use; the raw material powder collected by the micropowder collection system (hereinafter referred to as the collected raw material powder) is shaken The sieve is sieved, and the raw material powder with a bulk density of 0.20kg / l after sieving is collected for use;

[0049] S2: 95 parts by weight of commercially available zinc oxide after sieving and 2 parts by weight of raw material powder collected for standby are added to the hopper mixer for mixing, the mixing speed is 15 rpm, and the mixing time is 30 minutes.

[0050] S3: add the material mixed in S2 and the clay into the kneader according to the weight ratio of 97:3, mix, stir and knead at room temperature for 30 minutes, and add 2.5% ...

Embodiment 3

[0055] The preparation process of the fine desulfurizer in the present embodiment comprises the following steps:

[0056] S1: sieve commercially available zinc oxide through a vibrating sieve, and collect the raw material powder with a bulk density of 0.30kg / l after sieving for subsequent use; the raw material powder collected by the micropowder collection system (hereinafter referred to as the collected raw material powder) is shaken The sieve is sieved, and the raw material powder with a bulk density of 0.12 kg / l after sieving is collected for use;

[0057] S2: 97 parts by weight of commercially available zinc oxide after sieving and 1.5 parts by weight of raw material powder collected for standby are added to the hopper mixer for mixing, the mixing speed is 15 rpm, and the mixing time is 35 minutes.

[0058] S3: add the material after S2 mixing and cement into the kneader according to the weight ratio of 98.5:1.5, mix, stir and knead at room temperature for 35 minutes, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com