A kind of polylactic acid base film and preparation method thereof

A polylactic acid-based, polylactic acid technology, applied in the field of polylactic acid-based film and its preparation, can solve the problems of difficulty in maintaining transparency, low elongation at break, inability to withstand impact and impact, etc. Production application, preparation method is simple and easy to operate, and the effect of good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

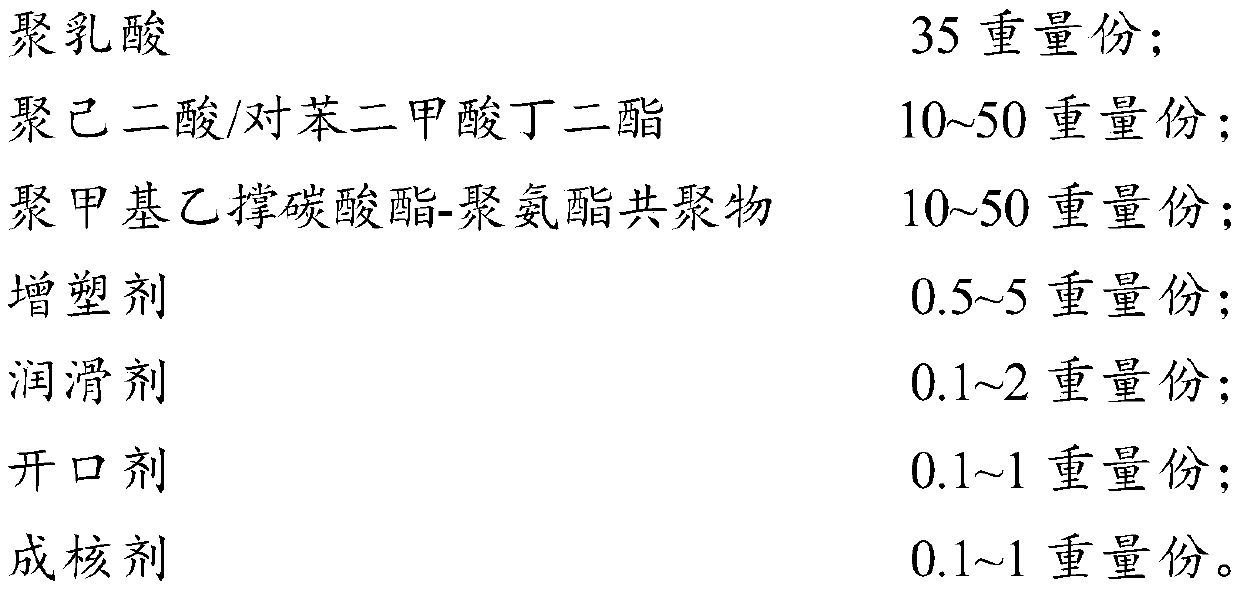

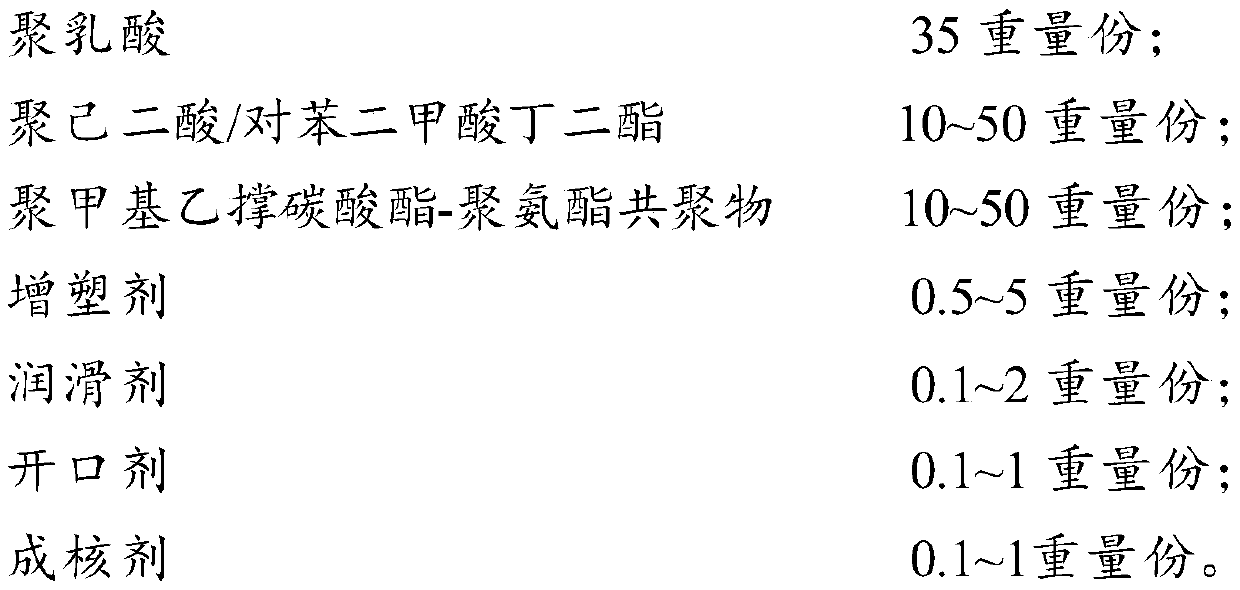

[0034] The present invention also provides a preparation method for the above-mentioned polylactic acid-based film, comprising the following steps:

[0035] a) mixing polylactic acid, polyadipate / butylene terephthalate, polymethylethylene carbonate-polyurethane copolymer, plasticizer, lubricant, blocking agent and nucleating agent to obtain a raw material mixture;

[0036] b) melting and extruding the raw material mixture through a twin-screw extruder to obtain a resin material;

[0037] c) The resin material is blown into a film by a film blowing machine to obtain a polylactic acid-based film.

[0038] Among them, the type, dosage and source of polylactic acid, polyadipate / butylene terephthalate, polymethylethylene carbonate-polyurethane copolymer, plasticizer, lubricant, blocking agent and nucleating agent, etc. The features are consistent with the above-mentioned technical solutions, and will not be repeated here.

[0039] In the present invention, in the step a), the mix...

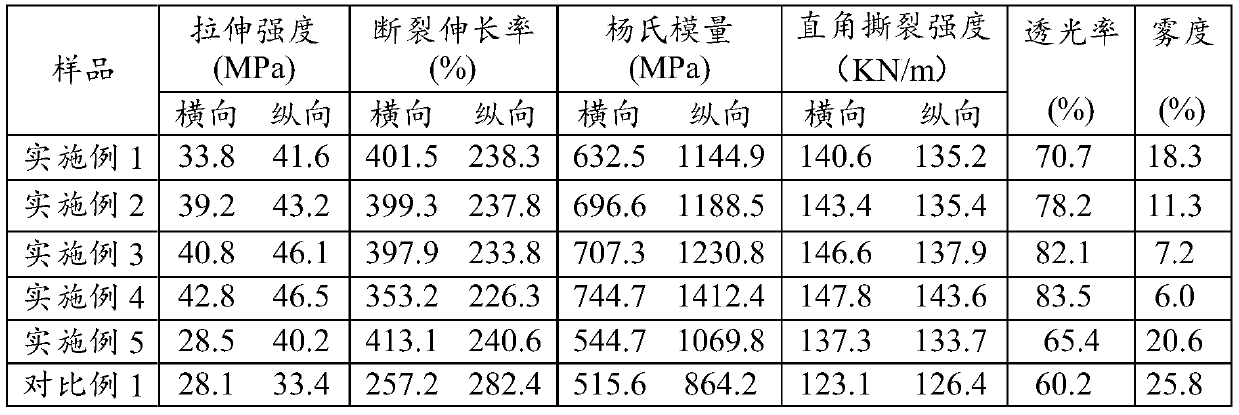

Embodiment 1

[0045] Raw material: 35 parts by weight of PLA, 41.5 parts by weight of PBAT, 20 parts by weight of PPCU, 1 part by weight of plasticizer GMS, 0.6 part by weight of plasticizer ATBC, 0.5 part by weight of lubricant EBS, 1 part by weight of blocking agent EA, nucleating agent talc Powder 0.4 parts by weight.

[0046] Preparation: Mechanically blend the above components in proportion for 5 minutes to obtain a raw material mixture; put the obtained raw material mixture into a twin-screw extruder, and the extrusion granulation conditions are as follows: ①The set temperature of the twin-screw extruder is a zone 120~140℃, zone 2 150~170℃, zone 3 160~180℃, zone 4 170~190℃, zone 5 170~190℃, zone 6 170~190℃, zone 7 170~190℃, zone 8 170 ~190°C; ②The head temperature is 170~190°C; ③The screw speed is 100~300rpm. After the raw material mixture is melted and extruded, water cooling, pelletizing and drying are carried out in sequence to obtain the resin material. Use the blown film machin...

Embodiment 2

[0048] Raw material: 35 parts by weight of PLA, 31.5 parts by weight of PBAT, 30 parts by weight of PPCU, 1 part by weight of plasticizer GMS, 0.5 part by weight of plasticizer ATBC, 0.6 part by weight of lubricant EBS, 1 part by weight of blocking agent EA, nucleating agent talc Powder 0.4 parts by weight.

[0049] Preparation: Prepare according to the preparation method of Example 1, and control the thickness of the film to be 0.02-0.04mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com