Fireproof silica gel soft package and manufacturing method thereof

A soft bag and silica gel technology, which is applied in the field of architectural decoration, can solve the problems of sponges being difficult to dry, easy to turn yellow, poor stain resistance of sponges, etc., and achieve the effects of environmentally friendly and pollution-free components, long service life and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

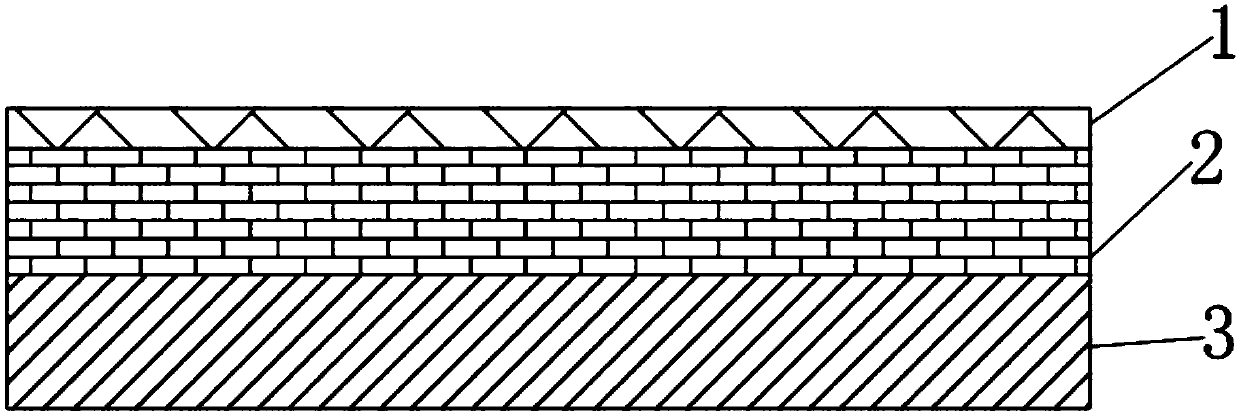

[0028] Mix 75 parts of vinyl silicone oil and 35 parts of white carbon black evenly, then add 115 parts of hydroxyl silicone oil with a viscosity of 1500Mpa.s and stir and mix evenly; then add 20 parts of hydroxyl silicone oil with a viscosity of 20Mpa. 3 parts of vinyl ring delay agent and stir and mix evenly; finally add 70 parts of hydrogen-containing silicone oil with a hydrogen atom content of 1.6% and mix evenly, and then put it in an oven at 130°C for 10 minutes, the density of the silicone foam layer 2 0.15kg / m 3 .

Embodiment 2

[0030] Mix 80 parts of vinyl silicone oil and 40 parts of white carbon black evenly, then add 120 parts of hydroxyl silicone oil with a viscosity of 1500Mpa.s and stir and mix evenly; then add 25 parts of hydroxyl silicone oil with a viscosity of 25Mpa. 3.5 parts of vinyl ring delay agent and stir and mix evenly; finally add 73 parts of hydrogen-containing silicone oil with a hydrogen atom content of 1.6% and mix evenly, and then place it in an oven at 130°C for 10 minutes, the density of the silicone foam layer 2 0.17kg / m 3 .

Embodiment 3

[0032] Mix 85 parts of vinyl silicone oil and 45 parts of white carbon black evenly, then add 125 parts of hydroxyl silicone oil with a viscosity of 1500Mpa.s and stir and mix evenly; then add 30 parts of hydroxyl silicone oil with a viscosity of 30Mpa. 4 parts of vinyl ring delay agent and stir and mix evenly; finally add 75 parts of hydrogen-containing silicone oil with a hydrogen atom content of 1.6% and mix evenly, and then put it in an oven at 130°C for 10 minutes, the density of the silicone foam layer 2 0.18kg / m 3 .

[0033] The silica gel foam layer prepared in Examples 1, 2, and 3 was tested, as shown in Table 1 below:

[0034] Table 1

[0035]

[0036]Among them, the oxygen index indicates the flame retardancy, and the flame retardancy effect increases with the increase of the oxygen index. When the oxygen index is greater than 27, it is a flame retardant material; the maximum smoke density is the measure of the amount of smoke generated under the specified expe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com