PVDF fluorocarbon powder coating and preparation method thereof

A powder coating, fluorocarbon technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of uneven mixing of PVDF resin and acrylic resin, uneven coating thickness, poor gloss and leveling, etc., to achieve finished products. High rate, balanced hardness and flexibility, good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

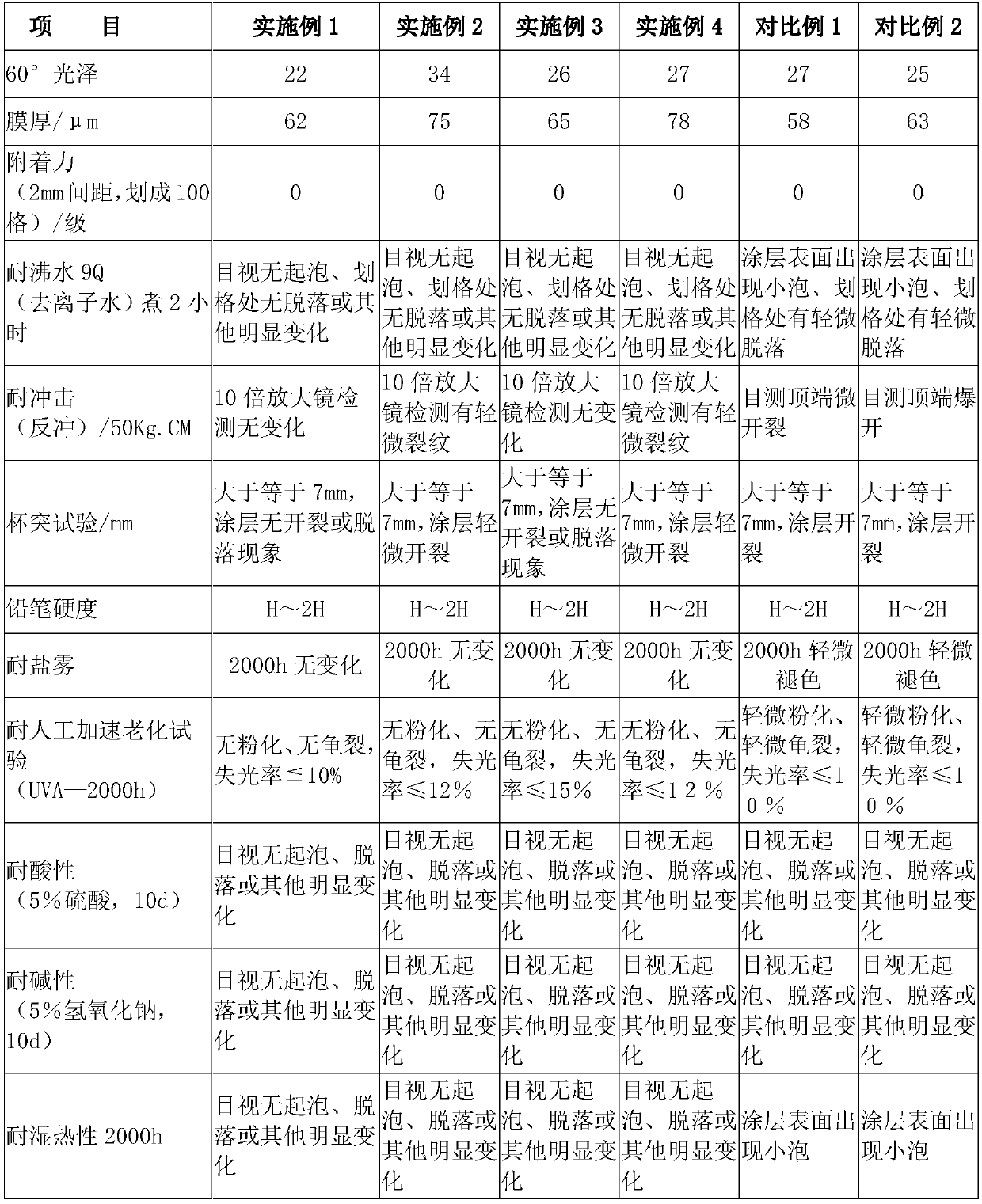

Examples

preparation example Construction

[0036] A kind of preparation method of synthesizing above-mentioned PVDF fluorocarbon powder coating, adopts melt mixing extrusion method, and its process step is:

[0037] Put the auxiliary solid resin and pigment into a high-speed mixer for high-speed dispersion mixing and frictional heat generation. The temperature of frictional heat generation is controlled at 50-70°C; 2) After mixing, add ultra-fine PVDF resin to the high-speed mixer to continue High-speed dispersion mixing and frictional heat generation, the temperature of frictional heat generation is controlled at 70-120°C; 3) The mixture obtained in step 2) is melted and extruded, cooled, dried, pressed into pellets, and the temperature of melted extrusion is The range is: 160-210°C. ; 4) Put the granulated pellets obtained in step 3) into the storage bin for spraying and freezing with liquid nitrogen, drenching and soaking to make them brittle, and the freezing temperature of liquid nitrogen is lower than or equal to...

Embodiment 1

[0039] The specific formula parameters are as follows:

[0040] 28 kg of titanium dioxide, the brand is DuPont R-960 in the United States; 25 kg of acrylic resin, 5 kg of alicyclic epoxy resin; 70 kg of PVDF resin (customized model); adhesion promoter of solid organic silicon phosphorus additives 1 kg and 0.2 kg of nano-modifier additives.

[0041] The concrete preparation steps of embodiment 1:

[0042] (1) Add all the titanium dioxide, acrylic resin, and cycloaliphatic epoxy resin into a high-speed mixer; carry out high-speed dispersion for 25 minutes, and the high-speed dispersion temperature is 65°C.

[0043] (2) After the above steps are completed, add all the PVDF resin (customized model) into the high-speed mixer; then disperse at high speed for 35 minutes, and the high-speed dispersion temperature is 85°C.

[0044] (3) The material mixture obtained in step (2) enters the extruder to be extruded into strips and cut into pellets with a diameter of 0.5-3mm, and the melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com