Lubricant oil and preparation method of same

A lubricating oil and base oil technology, applied in the field of anti-wear lubricating oil, can solve problems such as large amount of wear, unreasonable selection of additives, poor anti-wear and anti-friction performance of lubricating oil, etc., and achieve high fuel saving rate and good anti-friction Rust performance, good wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

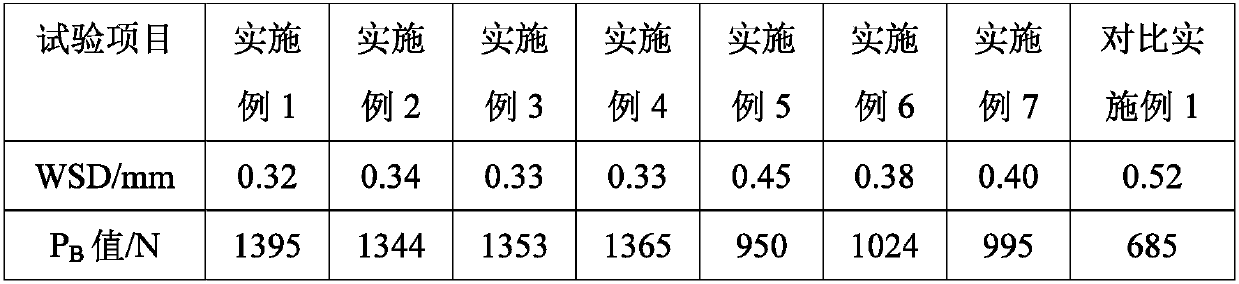

Examples

Embodiment 1

[0047] A kind of lubricating oil, is made up of following component by weight:

[0048] 120 parts of base oil

[0049] Anti-wear agent 15 parts

[0050] Anti-wear enhancer 8 parts

[0051] Antirust agent 7 parts.

[0052] Described base oil is the mixture of the mineral oil of ISO VG viscosity grade 100, castor oil and polyalphaolefin PAO15, and its mass proportion is 10: 2: 1;

[0053]The preparation method of described antiwear agent comprises the following steps:

[0054] S1, adding 2 parts by volume of sodium hypochlorite with a mass percentage concentration of 3% to 45 parts by volume of diesel oil to obtain sulfur-free fuel oil;

[0055] S2, remove all water and the sundries formed by sodium hypochlorite;

[0056] S3, blending 30 parts by volume of lead naphthenate with a mass percentage concentration of 24%, 15 parts by volume of sulfur-free fuel oil and 15 parts by volume of light mineral oil to form a blend;

[0057] S4. Slowly and uniformly heat the blend to 15...

Embodiment 2

[0062] A kind of lubricating oil, except that the base oil is mineral oil of ISO VG viscosity grade 100, other components, dosage ratio and preparation method are exactly the same as embodiment 1.

Embodiment 3

[0064] A lubricating oil, except that the base oil is a mixture of mineral oil and castor oil with a mass ratio of 5:1 ISO VG viscosity grade 100, other components, dosage ratios and preparation methods are exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com