HEMT device with back field plate structure and preparation method thereof

A technology of plate structure and back field, which is applied in the field of HEMT devices, can solve the problems of low thermal conductivity of sapphire substrates, achieve the effects of improving electric field distribution, solving back breakdown, and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

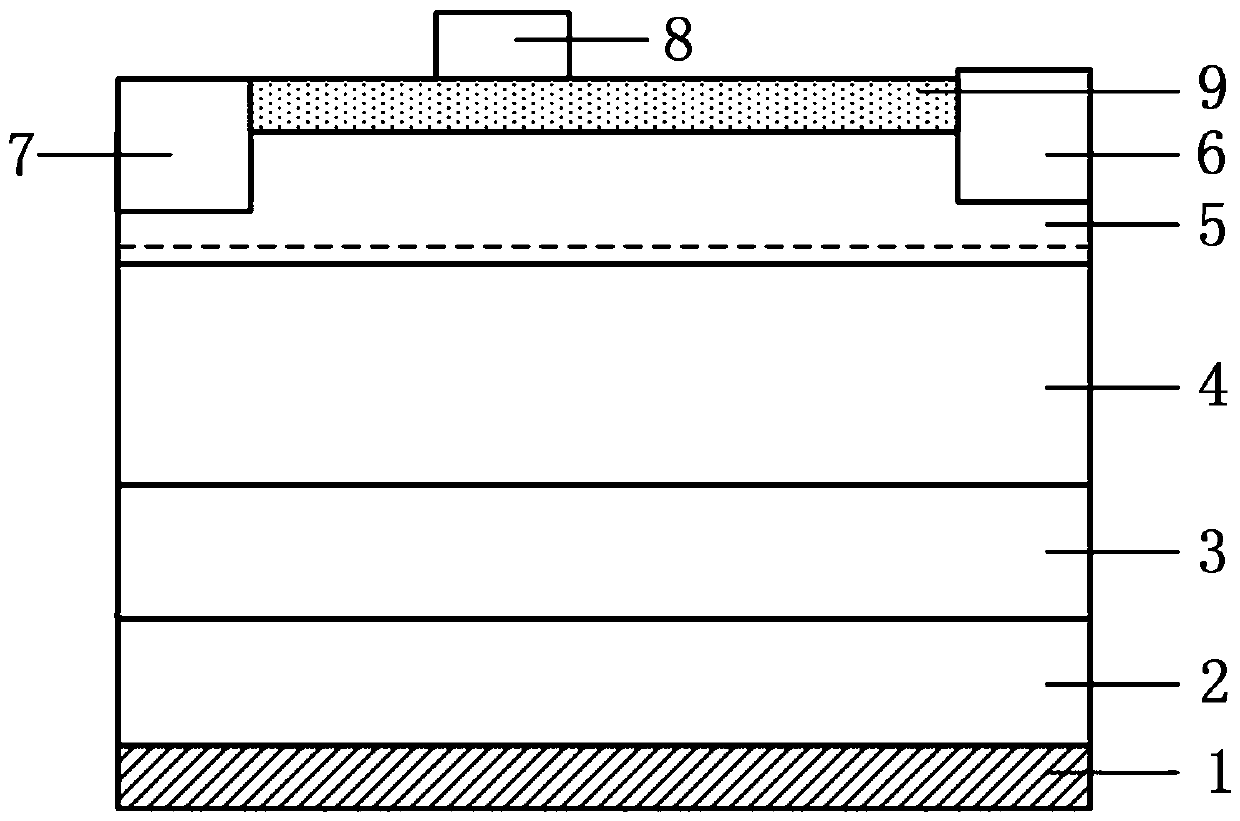

[0027] The structure of the present invention is as figure 1 As shown, from bottom to top are back field plate 1 , substrate 2 , buffer layer 3 , first semiconductor layer 4 , second semiconductor layer 5 and gate oxide layer 9 . Wherein, the drain electrode 6 and the source electrode 7 are provided on the second semiconductor layer 5, the first semiconductor layer 4 and the second semiconductor layer 5 are heterogeneous structures, and a two-dimensional electron gas channel is formed at the interface between the two, The drain 6 and the source 7 form an ohmic contact with the second semiconductor layer 5 and are connected through the two-dimensional electron gas channel. Meanwhile, a gate 8 is provided on the gate oxide layer 9 .

[0028] The materials of each layer in this embodiment are as follows: the back field plate 1 is a single-layer metal material Cu, the substrate 2 is a single-sided polished (0001) sapphire substrate, the buffer layer 3 is an AlN buffer layer, and ...

Embodiment 2

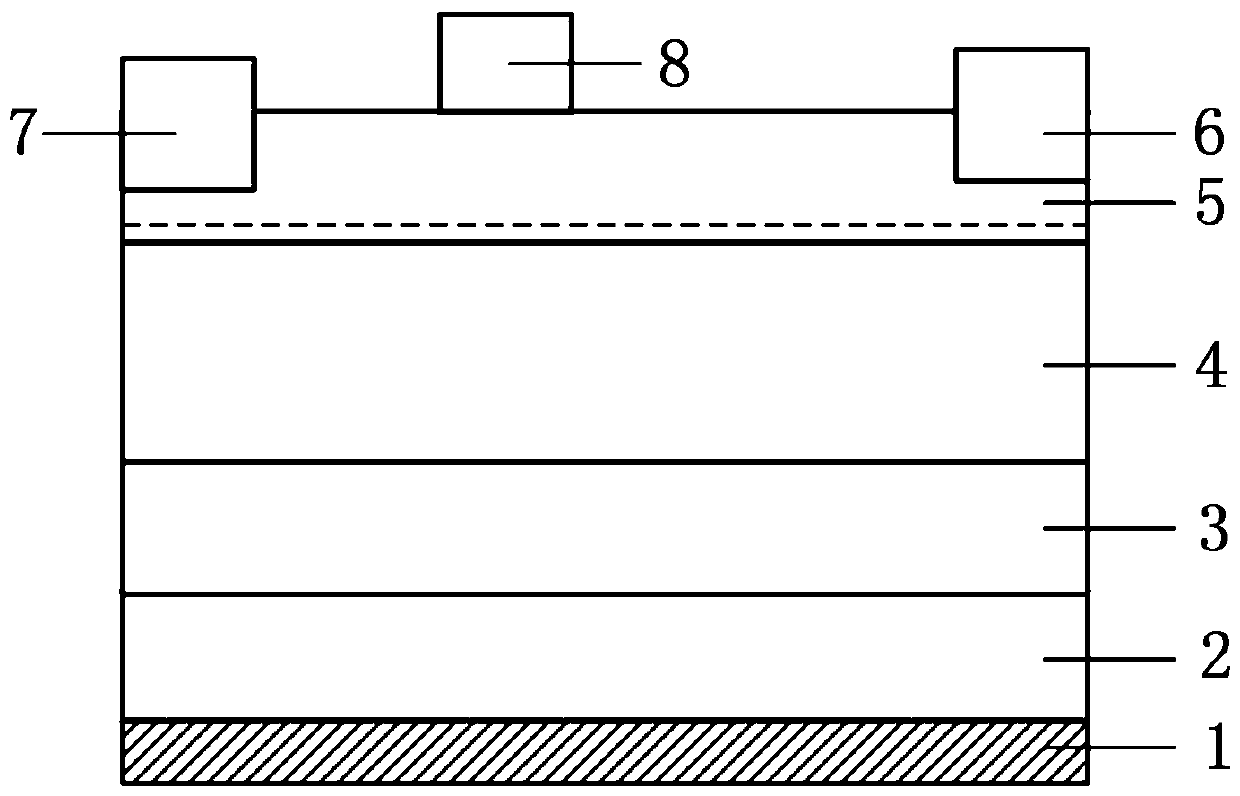

[0038] The structure of the present invention is as figure 2 As shown, from bottom to top are back field plate 1 , substrate 2 , buffer layer 3 , first semiconductor layer 4 and second semiconductor layer 5 . Among them, the drain 6, the source 7 and the gate 8 are arranged on the second semiconductor layer 5, the first semiconductor layer 4 and the second semiconductor layer 5 are heterostructures, and two-dimensional electrons are formed at the interface between the two. The gas channel, the drain 6 and the source 7 form an ohmic contact with the second semiconductor layer 5 and are connected through the two-dimensional electron gas channel.

[0039] The materials of each layer in this embodiment are as follows: the back field plate 1 is a Ni / Au alloy, the substrate 2 is a (001) surface AlN substrate polished on one side, the buffer layer 3 is an AlGaN buffer layer, and the first semiconductor layer 4 is GaN layer, the second semiconductor layer 5 is Al 0.82 In 0.18 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com