Method of manufacturing ZnO strip waveguide by carbon ion beam irradiation

A carbon ion beam, strip waveguide technology, applied in the direction of optical waveguide light guide, etc., can solve the problems of difficult optical waveguide structure and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Fabrication of ZnO Ridge Optical Waveguide

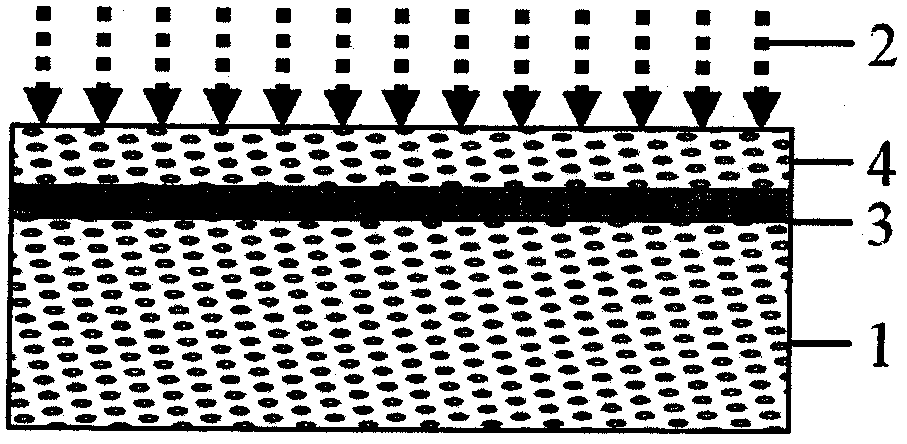

[0016] Preparation of planar waveguide: cut ZnO crystal (1) z-cut, size 5 mm×10 mm, thickness 0.5 mm, surface and end face optically polished. The ZnO crystal is cleaned with acetone, ethanol and deionized water; the prepared sample is placed in the accelerator target chamber, irradiated, the beam current is 55 nanoamperes, the energy is 4.5 MeV, and the dose is 2×10 15 ion / carbon ion per square centimeter (2), a barrier layer (3) with reduced refractive index is formed at the end of the ion beam under the crystal surface, and a planar waveguide (4) is formed between the layer and the air.

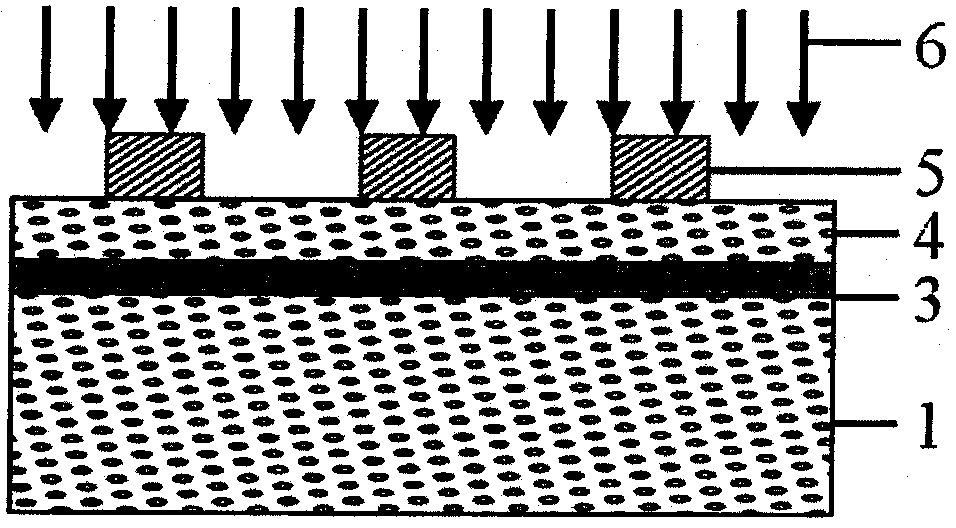

[0017] Preparation of surface mask: apply photoresist (5) on the polished surface of ZnO crystal with a high-speed coater, rotate at 3500 rpm, and bake at 80 degrees Celsius for 20 minutes. The photoresist is BP218 UV positive resist. Expose the photoresist with a photoresist plate, the photoresist plate is a 50mm×10mm chrome plate, the ...

Embodiment 2

[0021] Fabrication of ZnO Channel-Shaped Optical Waveguide

[0022] Sample polishing: cut ZnO crystal (1) z-cut, size 5 mm × 10 mm, thickness 0.5 mm, surface and end faces optically polished. After cleaning the ZnO crystals with acetone, ethanol, and deionized water, prepare the mask.

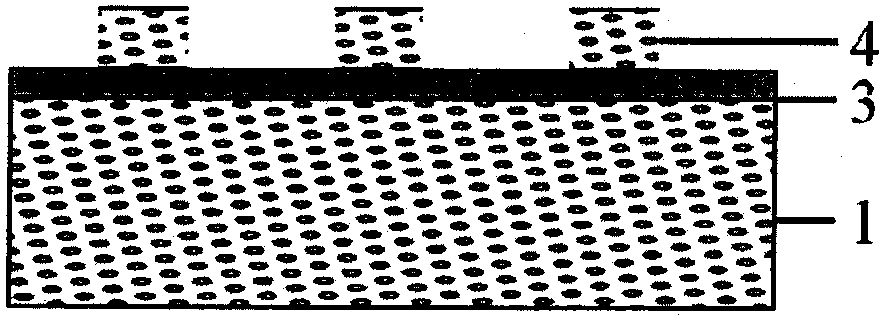

[0023] Preparation of surface mask: apply photoresist (5) on the polished surface of ZnO crystal with a high-speed coater, rotate at 3500 rpm, and bake at 80 degrees Celsius for 20 minutes. The photoresist is BP218 UV positive resist. Expose the photoresist with a photoresist plate, the photoresist plate is a 50mm×10mm chrome plate, the line shading part is 5mm, the non-shielding part is 45mm, and the stripe period is 50 microns. After exposure, develop with a special developing solution and rinse with deionized water to form a photoresist mask. The stencil produced after photolithography is heated to 160 degrees Celsius for 20 minutes under the protection of nitrogen. During this process, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com