Preparation method of curing agent for resin anchoring agent

A technology of resin anchoring agent and curing agent, which is applied in the field of preparation of curing agent for resin anchoring agent, which can solve the problems of high pressure in pipeline transportation of curing agent and reduction of metal elements, so as to improve appearance aesthetics and product quality, and reduce pipeline pressure , The effect of uniform and delicate appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method for curing agent for resin anchoring agent, comprising the following steps:

[0019] (1) Weigh the following raw materials by weight (g): 2,4-dichlorobenzoyl peroxide 4, propylene glycol 2, starch grafted sodium polyacrylate 0.5, water 50, inorganic filler 80, pigment 1;

[0020] (2) Mix propylene glycol and starch-grafted sodium polyacrylate, disperse at a high speed for 20 minutes at a speed of 2000r / min, heat up to 20°C, stir for 5 minutes, then add water and stir for 20 minutes to form a gel;

[0021] (3) Initiator, inorganic filler and pigment are added in order to the colloid, and the stirring is continued for 30 minutes until the materials are mixed homogeneously, and the curing agent for resin anchoring agent is obtained.

Embodiment 2

[0023] A preparation method for curing agent for resin anchoring agent, comprising the following steps:

[0024] (1) Weigh the following raw materials by weight (g): benzoyl peroxide 25, diethylene glycol 20, hydroxypropyl cellulose 1, pregelatinized starch 1, water 100, inorganic filler 140, pigment 2;

[0025] (2) Mix diethylene glycol, hydroxypropyl cellulose and pregelatinized starch, disperse at a high speed of 2500r / min for 15 minutes, heat up to 30°C, stir for 20 minutes, then add water and stir for 40 minutes to form a gel;

[0026] (3) Initiator, inorganic filler and pigment are added in order to the colloid, and the stirring is continued for 50 minutes until the materials are mixed homogeneously, and the curing agent for resin anchoring agent is obtained.

Embodiment 3

[0028] A preparation method for curing agent for resin anchoring agent, comprising the following steps:

[0029] (1) Weigh the following raw materials by weight (g): tert-butyl peroxybenzoate 32, ethylene glycol 15, n-butanol 10, xanthan gum 3, dextran 2, water 150, inorganic filler 160, pigment 3;

[0030] (2) Mix alcohol and thickener, disperse at a high speed of 3000r / min for 10 minutes, heat up to 40°C, stir for 30 minutes, then add water and stir for 60 minutes to form a gel;

[0031] (3) Initiator, inorganic filler and pigment are added in order to the colloid, and the stirring is continued for 60 minutes until the materials are mixed homogeneously, and the curing agent for resin anchoring agent is obtained.

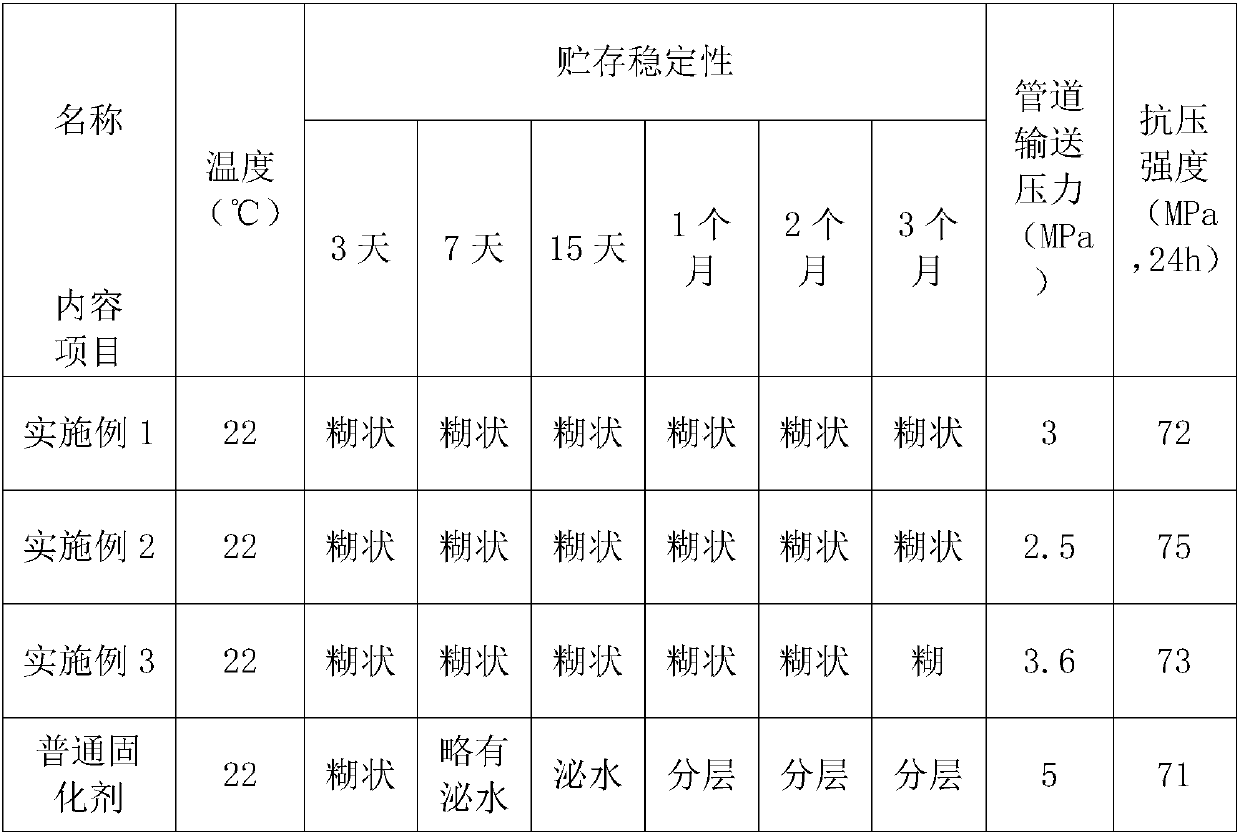

[0032] The compressive strength of the 4×4×4 test piece was made with the resin anchoring agent cement prepared in the above-mentioned Examples 1-3 at a solid glue ratio of 5%.

[0033] The following table 1 is the comparison of the effects of the curing agent for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com