Extraction method for improving content of water-soluble dietary fibers in square bamboo shoots

A technology of dietary fiber content and extraction method, which is applied in the functions of food ingredients, food processing, food science, etc., can solve the problems of breaking glycosidic bonds, increasing SDF content, and DF crystal structure being easily attacked by water molecules. Simple, improved water-soluble dietary fiber content, excellent physicochemical properties, and effects of hypoglycemic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

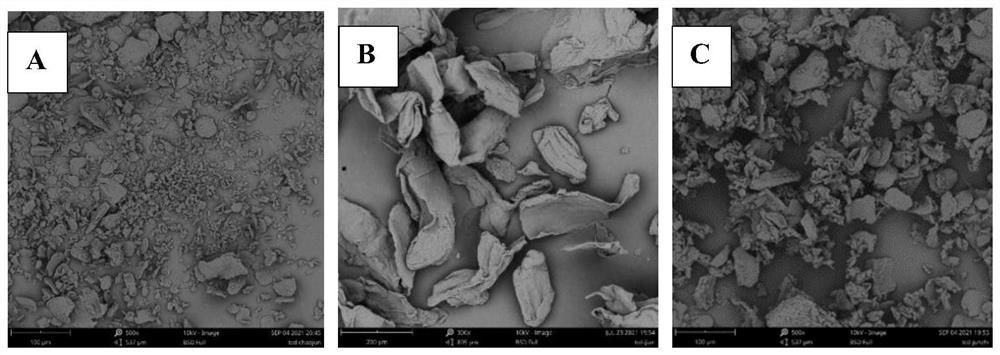

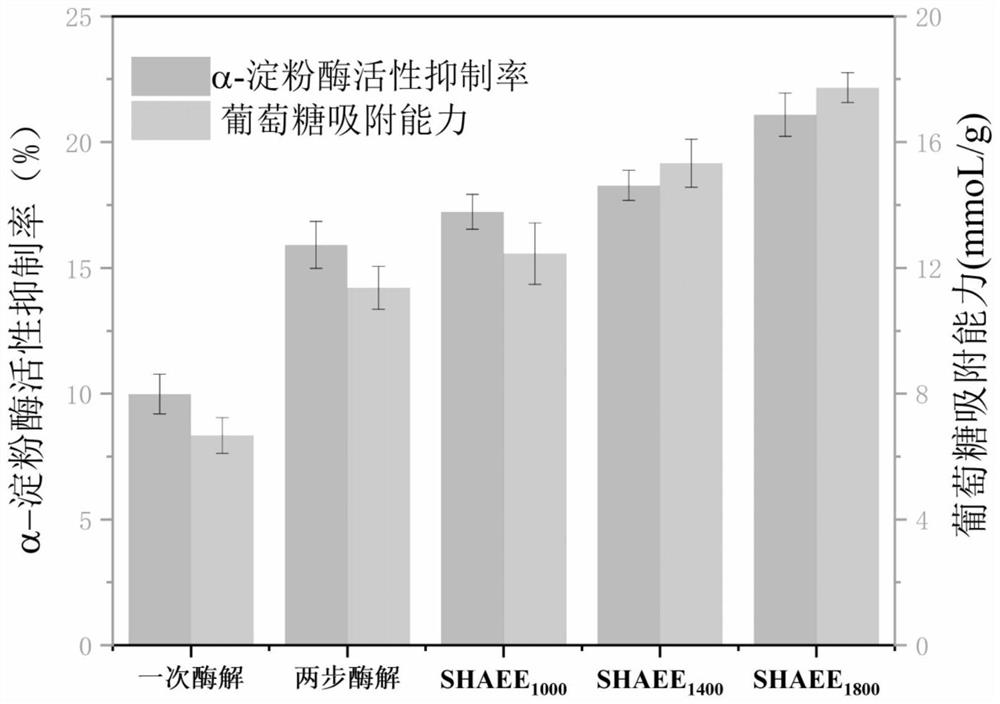

[0049] Take the leftovers of 1kg of canned square bamboo shoots, cut them into uniform slices, and freeze-dry them in vacuum for 24 hours. The dried square bamboo shoots were preliminarily pulverized with an ordinary pulverizer to obtain about 90 g of square bamboo shoots coarse powder. Weigh 20 g of square bamboo shoots coarse powder into a 1000 mL beaker, add deionized water at a ratio of 1:40 (w / w), mix and shake well, set the gear gap to 10 μm, and use a colloid mill to process twice. The high-pressure homogenization pretreatment was carried out under the condition that the homogenization pressure was 50MPa and the homogenization times were 2 times. After that, high-temperature cooking treatment was performed at a temperature of 115° C. for 15 minutes. The solution obtained from the pretreatment was placed in a water bath, and BSDF was extracted with the aid of shear homogenization at a shear rate of 1000 r / min. The pH of the solution was adjusted to 6 with malic acid an...

Embodiment 2

[0051] Take 2kg of leftovers from square bamboo shoots, cut into uniform slices, and freeze-dried in vacuum for 29h. The dried square bamboo shoots were placed in a high-speed universal pulverizer for preliminary pulverization to obtain about 190 g of square bamboo shoots coarse powder. Weigh 20 g of square bamboo shoots coarse powder into a 1000 mL beaker, add deionized water at a ratio of 1:40 (w / w), mix well, and use a colloid mill with a gear gap of 30 μm for three times. The mixed solution obtained by the colloid mill was subjected to high-pressure homogenization pretreatment under the conditions of a homogenization pressure of 70 MPa and three times of homogenization. After that, it was placed in an autoclave, and subjected to high-temperature cooking treatment at a temperature of 121° C. for 20 minutes. Then, with the aid of shear homogenization at a shear rate of 1000-1800 r / min, two enzymatic hydrolysis was performed to extract BSDF. The pH of the solution was adjus...

Embodiment 3

[0053] Take 3kg of leftovers from canned bamboo shoots, clear water bamboo shoots and other production and processing, cut into uniform thin slices, and freeze-dried in vacuum for 34 hours. Then, the dried square bamboo shoots are pulverized with a plant tissue masher to obtain about 300 g of square bamboo shoots coarse powder. Weigh 20 g of square bamboo shoots coarse powder into a 1000 mL beaker, add deionized water at a ratio of 1:40 (w / w), mix well, set the gear gap to 40 μm, and use a colloid mill for 5 treatments. The mixed liquid obtained by the colloid mill was subjected to high-pressure homogenization pretreatment, the homogenization pressure was 90 MPa, and the homogenization times were 4 times. After that, a high-temperature cooking treatment was performed at a temperature of 130° C. for 30 minutes. With the aid of shear homogenization at a shear rate of 1800 r / min, the solution obtained from the pretreatment was heated in a water bath to extract BSDF. Use malic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com