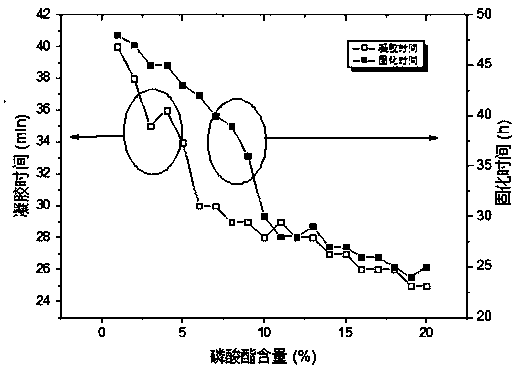

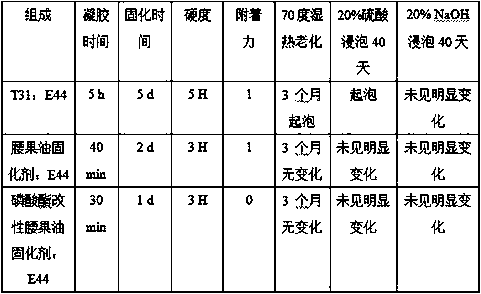

Preparation method and application of phosphate modified cashew nut oil curing agent

A technology of cashew nut oil and phosphoric acid ester is applied in the field of coating resins and achieves the effects of wide sources, simple and convenient production process and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the phosphoric acid ester modified cashew nut oil solidifying agent of the present embodiment may further comprise the steps:

[0028] Step (1), add 3.7 kg of ethylene glycol solution into the 10L reactor, turn on the jacket circulation, and add 1.4 kg of phosphorus pentoxide to the ethylene glycol solution in ten equal portions under the stirring condition of 800 rpm. Esterification reaction, control the temperature below 50°C;

[0029] Step (2), after adding the materials, stir for half an hour, raise the temperature to 100 degrees Celsius and react for half an hour, discharge the material to the storage tank while it is hot, and cool to room temperature to obtain polyol phosphate;

[0030] Step (3), first add 3kg of cashew nut oil phenalkamine curing agent to another 10L reaction kettle, start the jacket circulation, slowly add 30g of the above-mentioned polyol phosphate under stirring, and the addition rate is based on the temperature rise ...

Embodiment 2

[0032] The preparation method of the phosphoric acid ester modified cashew nut oil solidifying agent of the present embodiment may further comprise the steps:

[0033] Step (1), add 3.5 kg of ethylene glycol, glycerol, and monoglyceride solution into the 10L reaction kettle, open the jacket circulation, and add 1.4 kg of phosphorus pentoxide to the above solution under the stirring condition of 1200 rpm Add in ten equal portions for esterification reaction, and control the temperature below 50°C;

[0034] Step (2), after adding the materials, stir for half an hour, raise the temperature to 100 degrees Celsius and react for half an hour, discharge the material to the storage tank while it is hot, and cool to room temperature to obtain polyol phosphate;

[0035] Step (3), first add 3kg of cashew nut oil phenalkamine curing agent to another 10L reaction kettle, start the jacket circulation, slowly add 300g of the above-mentioned polyol phosphate under stirring, and the addition r...

Embodiment 3

[0037] Step (1), add 3.7 kg of ethylene glycol and monoglyceride solution into a 10L reactor, open the jacket circulation, and add 0.5 kg of pentoxide to the glycerol monostearate solution under stirring at 1500 rpm Diphosphorus is added in two equal parts for esterification reaction, and the temperature is controlled below 50°C;

[0038] Step (2), after adding the materials, stir for half an hour, under reduced pressure, raise the temperature to 100 degrees Celsius and react for half an hour, further raise the temperature to 120 degrees Celsius to distill off unreacted ethylene glycol, cool to room temperature, and obtain multi-component alcohol phosphate;

[0039] Step (3), first add 3kg of cashew nut oil phenalkamine curing agent to another 10L reaction kettle, start the jacket circulation, slowly add 600g of the above polyol phosphate under stirring, continue to stir for 1 hour, and then unload to the storage tank Cans get different phosphate-modified cashew butter harden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com