Adhesive composition for conductive members

A technology of conductive components and adhesives, applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc., can solve the problems of oxidative degradation of adherends, achieve corrosion inhibition, The effect of preventing oxidation deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

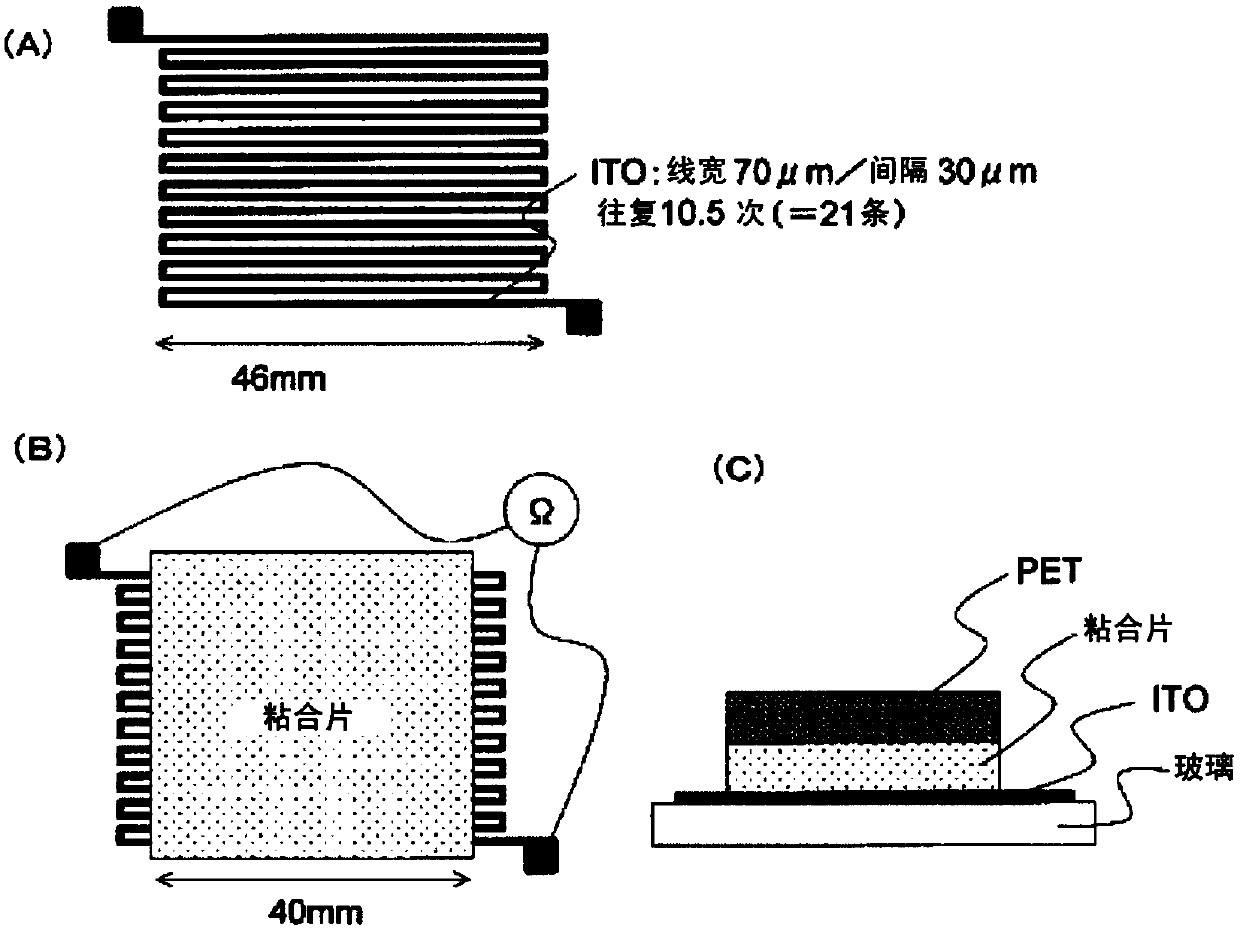

Method used

Image

Examples

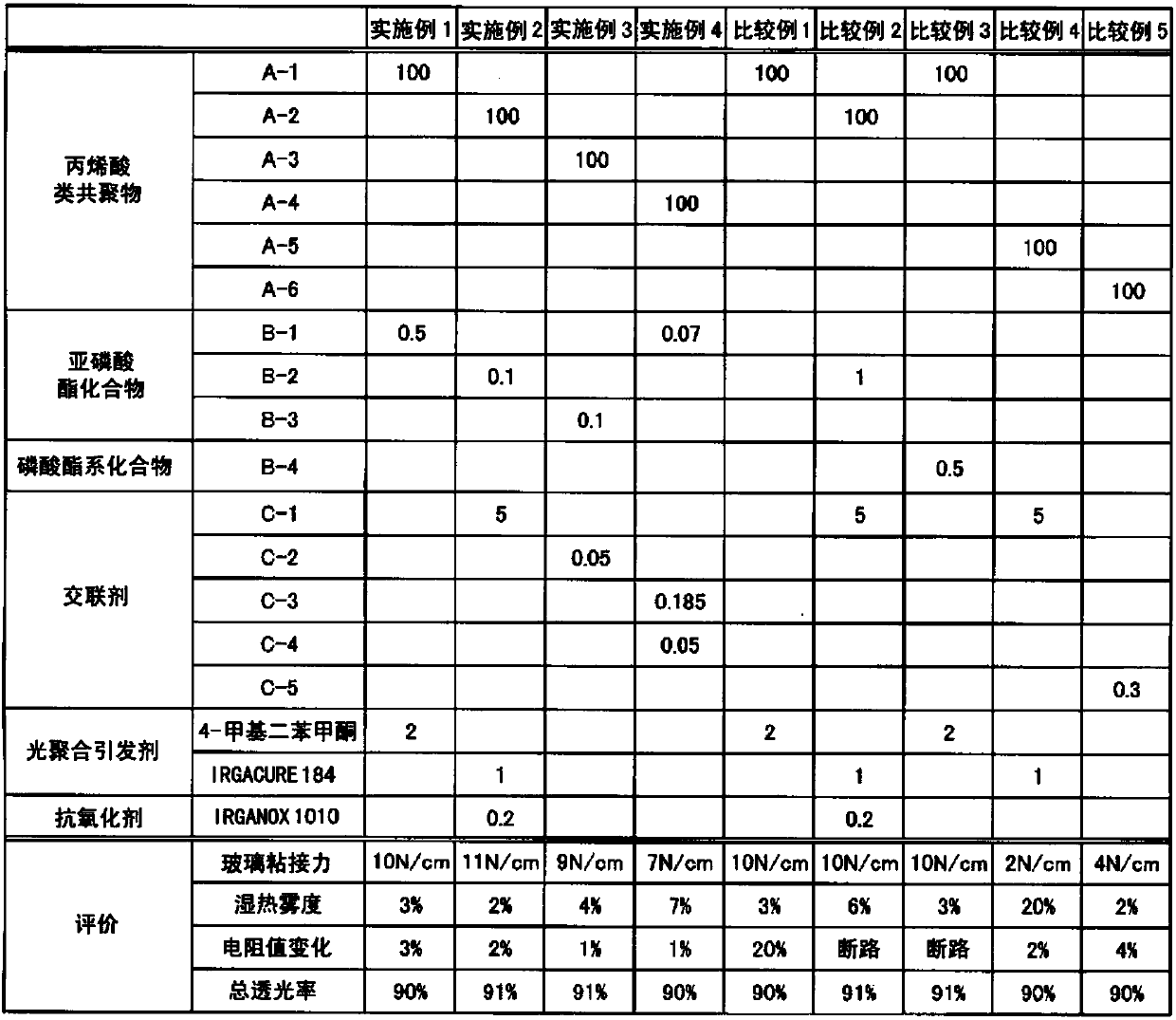

Embodiment 1

[0089] With respect to 76 mass parts of 2-ethylhexyl acrylate, 20 mass parts of vinyl acetate, 4 mass parts of acrylic acid copolymer (A-1, mass average molecular weight 400,000) 1kg, add as phosphite compound 5 g of tris(2,4-di-tert-butylphenyl) phosphate (B-1) ("IRGAFOS168" manufactured by BASF Corporation) and 20 g of 4-methylbenzophenone as a photopolymerization initiator were uniformly mixed, Adhesive composition 1 was obtained. Copolymer (A-1) is a copolymer containing 4% by mass of carboxyl group-containing (meth)acrylate or vinyl monomer.

[0090] Next, a peeled polyethylene terephthalate film (Mitsubishi Plastics Co., Ltd., DIAFOIL MRV, thickness 100 μm), and a peeled polyethylene terephthalate film (Mitsubishi Plastics Co., Ltd. Co., Ltd. product, DIAFOIL MRQ, thickness 75 μm) sandwiched the above-mentioned pressure-sensitive adhesive composition 1, and shaped it into a sheet shape using a laminator so that the thickness would be 150 μm.

[0091] By means of the pe...

Embodiment 2

[0093] Add triphosphite as a phosphite compound to 1 kg of a copolymer (A-2, mass average molecular weight: 300,000) consisting of 81 parts by mass of butyl acrylate, 15 parts by mass of methyl methacrylate, and 4 parts by mass of acrylic acid. 1 g of decyl ester (B-2) (“Adekastab 3010” manufactured by ADEKA CORPORATION), 50 g of glyceryl dimethacrylate (C-1) (manufactured by Shin-Nakamura Chemical Co., Ltd., NK Ester 701) as a cross-linking agent, as a photopolymerization 10 g of IRGACURE 184 (manufactured by BASF Corporation) as an initiator and 2 g of IRGANOX 1010 (manufactured by BASF Corporation) as an antioxidant were uniformly mixed to obtain an adhesive composition 2 . Copolymer (A-2) is a copolymer containing 4% by mass of carboxyl group-containing (meth)acrylate or vinyl monomer.

[0094] Next, the aforementioned pressure-sensitive adhesive composition 2 was molded into a sheet shape on a peeled polyethylene terephthalate film (manufactured by Mitsubishi Plastics Cor...

Embodiment 3

[0096] Solids of an ethyl acetate diluted solution of an acrylic copolymer (A-3, mass average molecular weight: 500,000) consisting of 74 parts by mass of butyl acrylate, 24 parts by mass of 2-ethylhexyl acrylate, and 2 parts by mass of acrylic acid Component 1kg, 3,9-bis(decyloxy)-2,4,8,10-tetraoxa-3,9-diphosphaspiro[5.5]undecane (B -3) 1 g of (JPE-10 manufactured by Johoku Chemical Co., Ltd.), 0.5 g of TETRAD-X (C-2) (manufactured by Mitsubishi Gas Chemical Co., Ltd.) as an amine-based cross-linking agent, mixed uniformly to make a bond Dosage Composition3. Copolymer (A-3) is a copolymer containing 2% by mass of carboxyl group-containing (meth)acrylate or vinyl monomer.

[0097] Next, the adhesive composition 3 was coated on a peeled polyethylene terephthalate film (manufactured by Mitsubishi Plastics Corporation, DIAFOIL MRV, thickness 100 μm) so that the thickness after drying became 50 μm, and then Drying was carried out at 70° C. for 5 minutes to obtain a sheet-shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com