Fuyanting granule and preparation method thereof

A technology of Fuyanting and granules, which is applied in the field of Fuyanting granules and its preparation, can solve the problems of easy loss of active ingredients, small loading capacity of tablets, and incomplete active ingredients, so as to promote extraction, accelerate dissolution rate, and promote high-efficiency and the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

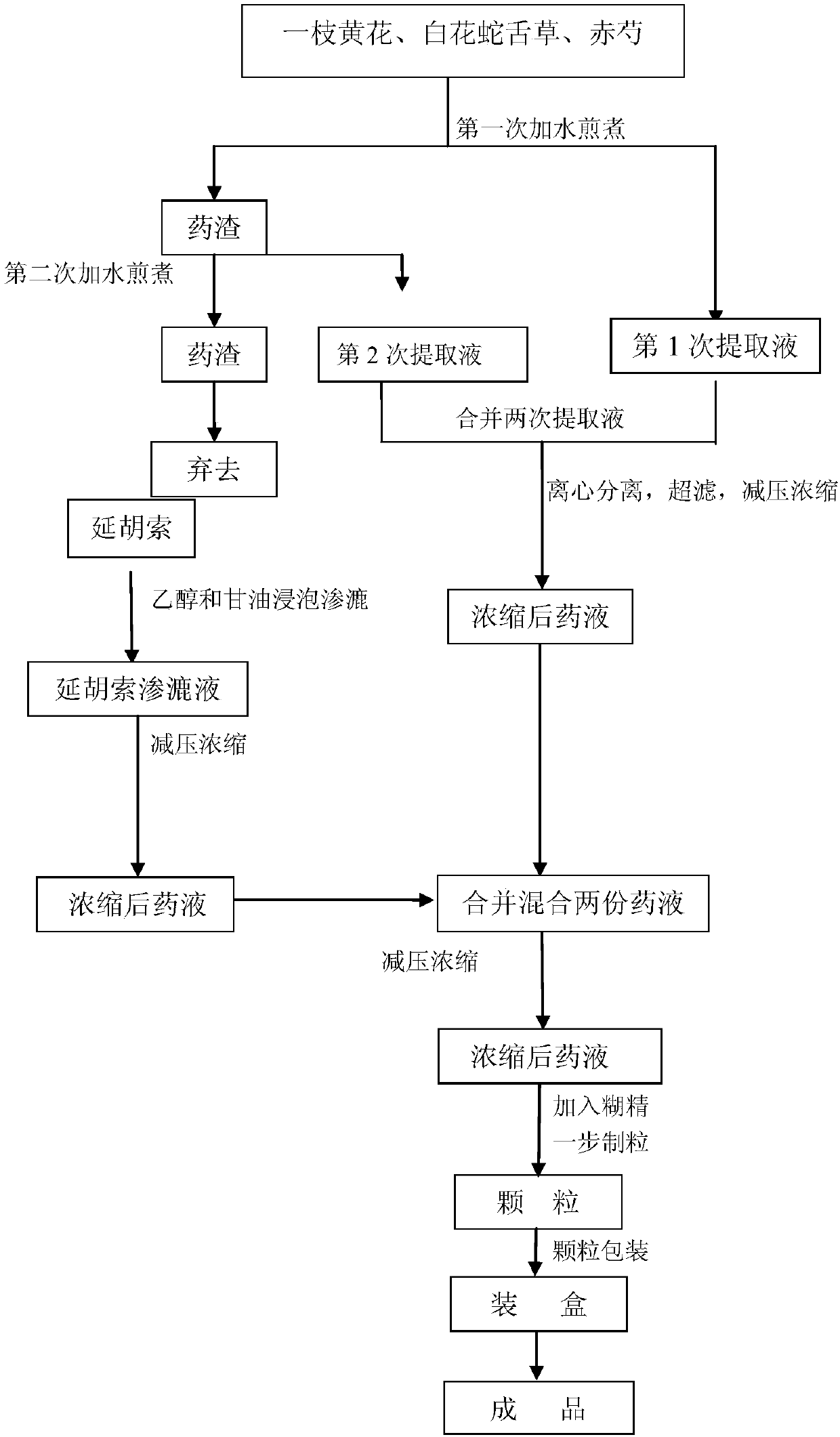

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh 1000g of Solidago, 1000g of Hedyotis diffusa and 667g of Radix Paeoniae Rubra, add 15 and 10 times the amount of glycerin to the water solution and decoct twice, among which Hedyotis diffusa is added to the solution twice for decoction Boil, each time for 1.5 hours, and filter in several times to obtain the primary extract and the secondary extract respectively, and then mix the two extracts; wherein the volume fraction of glycerin in the aqueous solution is 10%, and each component is decocted before Place in a ball mill jar equipped with dry ice for ball milling, and pass through 350 meshes to obtain a fine powder;

[0030] (2) Use a centrifuge at 4000rpm / min to separate the mixture of the two extracts for 30 minutes, take the upper layer of the centrifuge for ultrafiltration, and then concentrate the obtained filtrate under reduced pressure to obtain a concentrated solution with a relative density of 1.15. The density of water is measured at 65°C, and a memb...

Embodiment 2

[0035] (1) Weigh 800g of goldenrod, 800g of Hedyotis diffusa and 500g of Radix Paeoniae Rubra, add 15 and 10 times the amount of glycerin solution to decoct twice according to the weight ratio, and add Hedyotis diffusa into the solution twice for decoction Boil, each time for 1 hour, and filter in several times to obtain the primary extract and the secondary extract respectively, and then mix the two extracts; the volume fraction of glycerol in the aqueous solution is 10%, and each component is mixed before decocting Place in a ball mill jar equipped with dry ice for ball milling, and pass through 350 meshes to obtain a fine powder;

[0036] (2) Use a centrifuge at 4000rpm / min to separate the mixture of the two extracts for 60 minutes, take the upper layer of the centrifuge for ultrafiltration, and then concentrate the obtained filtrate under reduced pressure to obtain a concentrated solution with a relative density of 1.25. The density of water is measured at 65°C, and a memb...

Embodiment 3

[0041](1) Weigh 900g of Solidago, 900g of Hedyotis diffusa and 600g of Radix Paeoniae Rubra, add 15 and 10 times the amount of glycerin to the water solution and decoct twice, among which Hedyotis diffusa is added to the solution twice for decoction Boil for 2 hours each time, and filter in several times to obtain the primary extract and the secondary extract respectively, and then mix the two extracts; the volume fraction of glycerin in the aqueous solution is 10%, and each component is mixed before decocting Place in a ball mill jar equipped with dry ice for ball milling, and pass through 350 meshes to obtain a fine powder;

[0042] (2) Use a centrifuge at 4000rpm / min to separate the mixture of the two extracts for 45 minutes, take the upper layer of the centrifuge for ultrafiltration, and then concentrate the obtained filtrate under reduced pressure to obtain a concentrated solution with a relative density of 1.20. The density of water is measured at 65°C, and a membrane wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com