Master batch with heat storage and insulation functions, master batch product and preparation method of master batch

A thermal insulation product and heat storage technology, which is applied in the manufacture of rayon, textiles and paper, single-component polyester rayon, etc., can solve the problem of no light absorption heat storage effect, limited heat preservation effect, and poor far-infrared radiation efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: Preparation of heat storage heat preservation masterbatch and heat preservation products

[0050]

[0051] After fully mixing the compound powder of tungsten bronze compound, antimony-doped tin oxide and titanium nitride, dispersant and masterbatch carrier polymer with a certain proportion, using a high-speed mixer, the twin-screw extruder is used to Blending, melting and extruding the well-mixed mixture at a temperature of 250°C to 280°C to obtain a heat storage and heat preservation masterbatch.

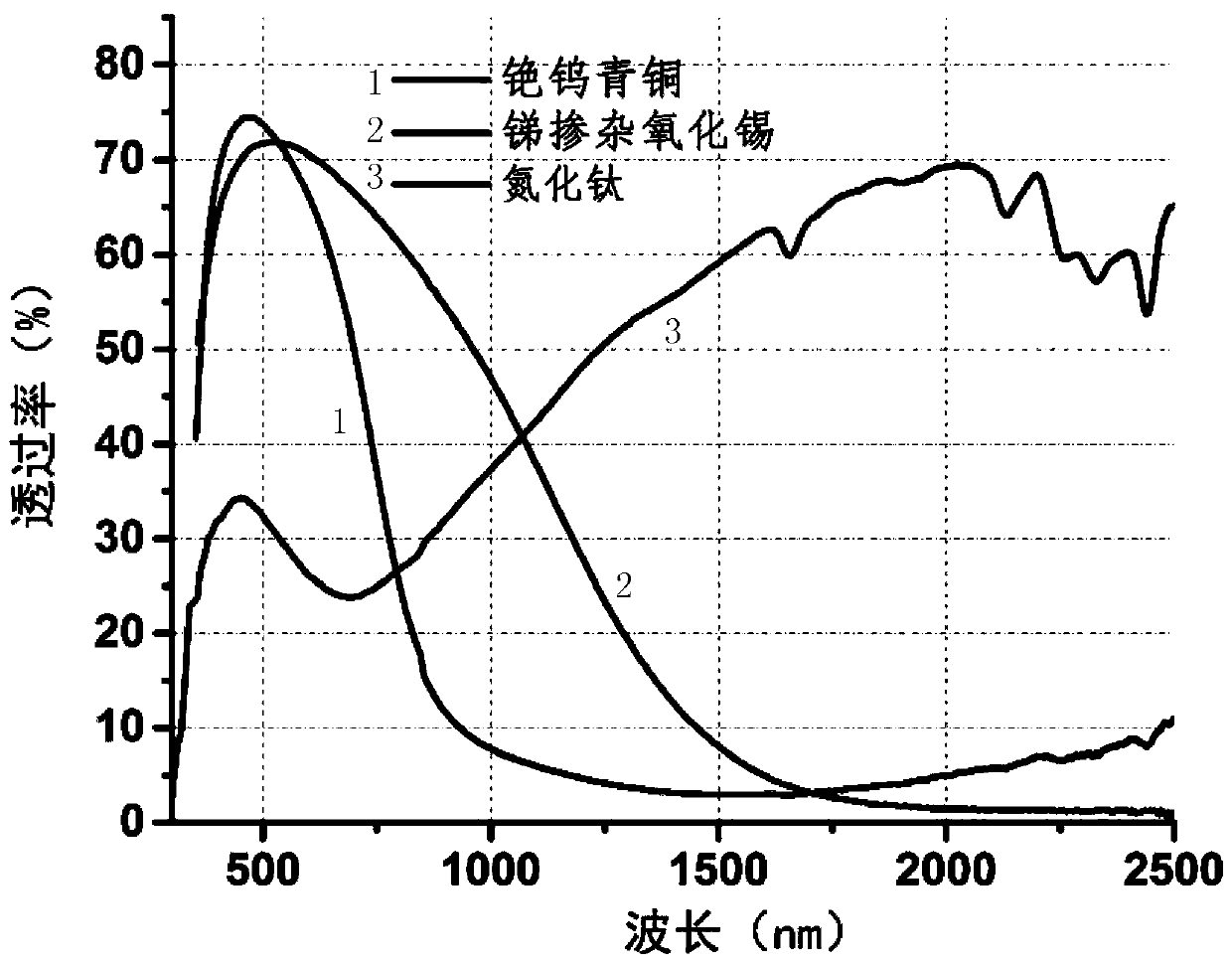

[0052] In this example, the inorganic ceramic powders with photothermal response effect were all synthesized by the inventors through solid phase method. Among them, tungsten bronze is cesium tungsten bronze with Cs 0.32 WO 3 The molecular formula, the particle size is between 40nm and 100nm. The atomic ratio of antimony to tin in antimony-doped tin oxide is 1:9, and the particle size is between 5nm and 25nm. The particle size of titanium nitride is betwe...

Embodiment 2

[0060] Embodiment 2: Preparation of thermal storage and thermal insulation masterbatch and thermal insulation products

[0061]

[0062] After fully mixing the compound powder of tungsten bronze compound, antimony-doped tin oxide and titanium nitride, dispersant and masterbatch carrier polymer with a certain proportion, using a high-speed mixer, the twin-screw extruder is used to Blending, melting and extruding the well-mixed mixture at a temperature of 220°C to 250°C to obtain a heat storage and heat preservation masterbatch.

[0063] The inorganic powders with photothermal response effect in this example were all synthesized by the inventor himself (the synthesis method is the same as in Example 1). Among them, tungsten bronze is cesium tungsten bronze with Cs 0.32 WO 3 Molecular formula, the particle size is between 40nm and 100nm; the atomic ratio of antimony to tin in antimony-doped tin oxide is 1:9, the particle size is between 5nm and 25nm; the particle size of tita...

Embodiment 3

[0069] Embodiment 3: Preparation of thermal storage and thermal insulation masterbatch and thermal insulation products

[0070] This embodiment is similar to Embodiment 2. Compared with Embodiment 2, this embodiment has the following differences.

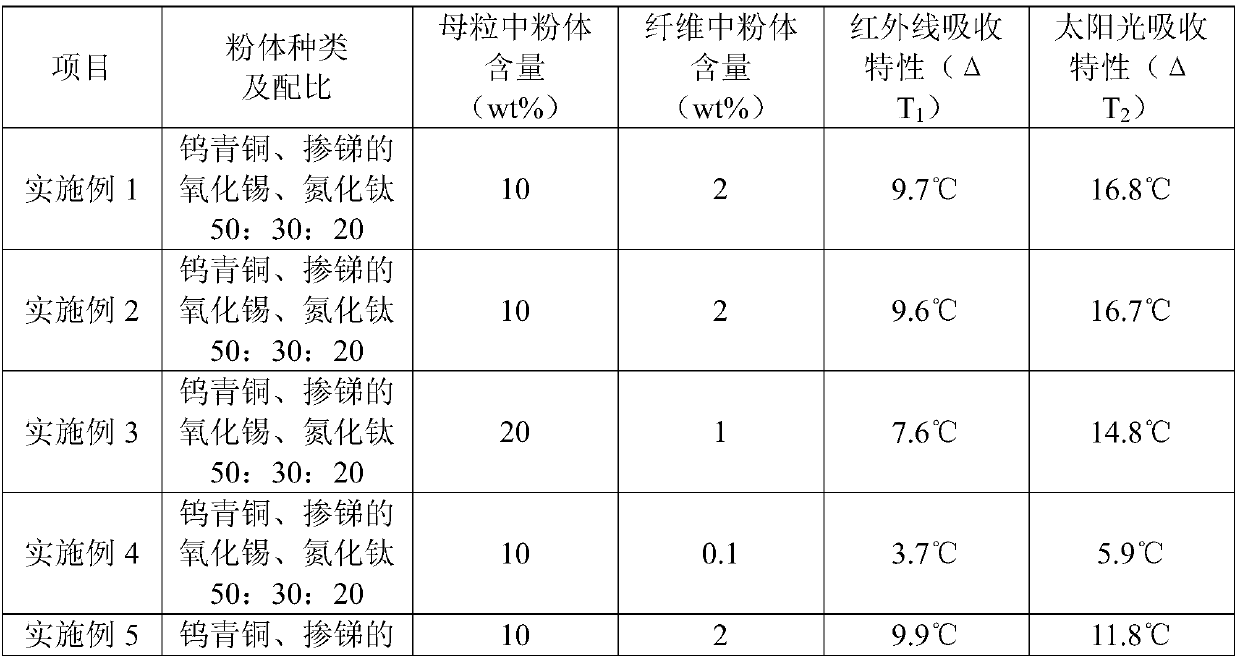

[0071] In the production of heat storage and heat preservation masterbatch, the mass ratio of inorganic ceramic powder with photothermal effect, dispersant and carrier polymer is 1:0.1:3.9, that is, based on the total mass of the heat storage heat preservation masterbatch, it has light and heat The content of thermally responsive inorganic ceramic powder is 20% by mass.

[0072] In the production of heat storage and heat preservation fibers, the heat storage and heat preservation masterbatch is mixed with the fiber matrix polymer at a mass ratio of 1:19. Based on the total mass of the heat storage and heat preservation fiber, the fiber contains 1 mass percent of inorganic ceramic powder with photothermal response effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com