Working electrolyte of aluminum electrolytic capacitor for 500-WV strobe lamp and preparation method thereof

A technology of aluminum electrolytic capacitors and preparation methods, applied in electrolytic capacitors, capacitors, circuits, etc., to achieve the effects of excellent stroboscopic characteristics, reduced ion collisions, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

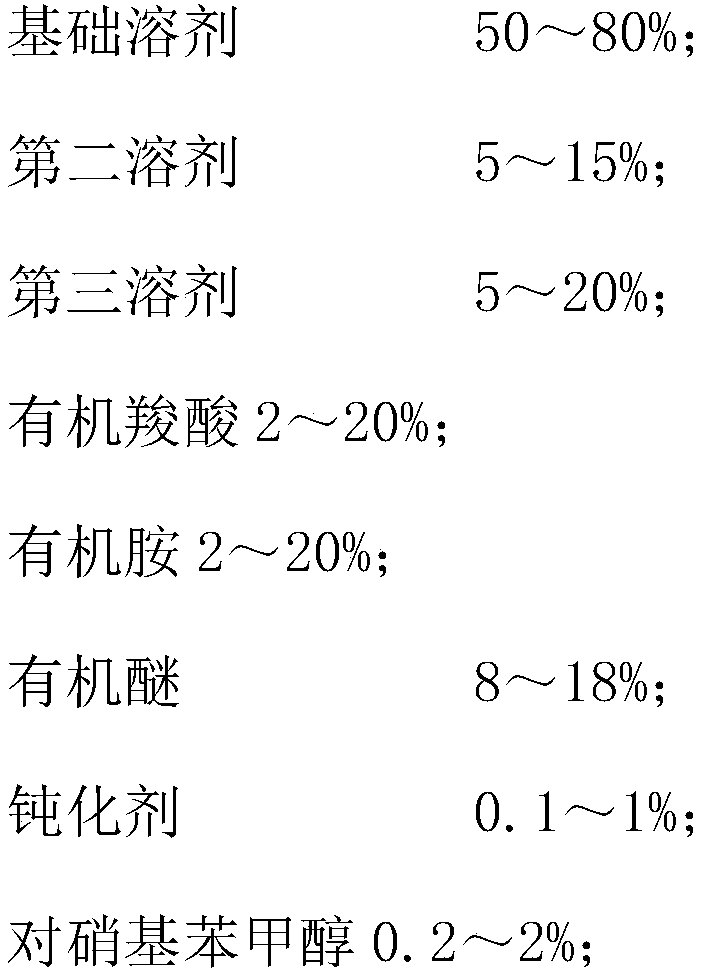

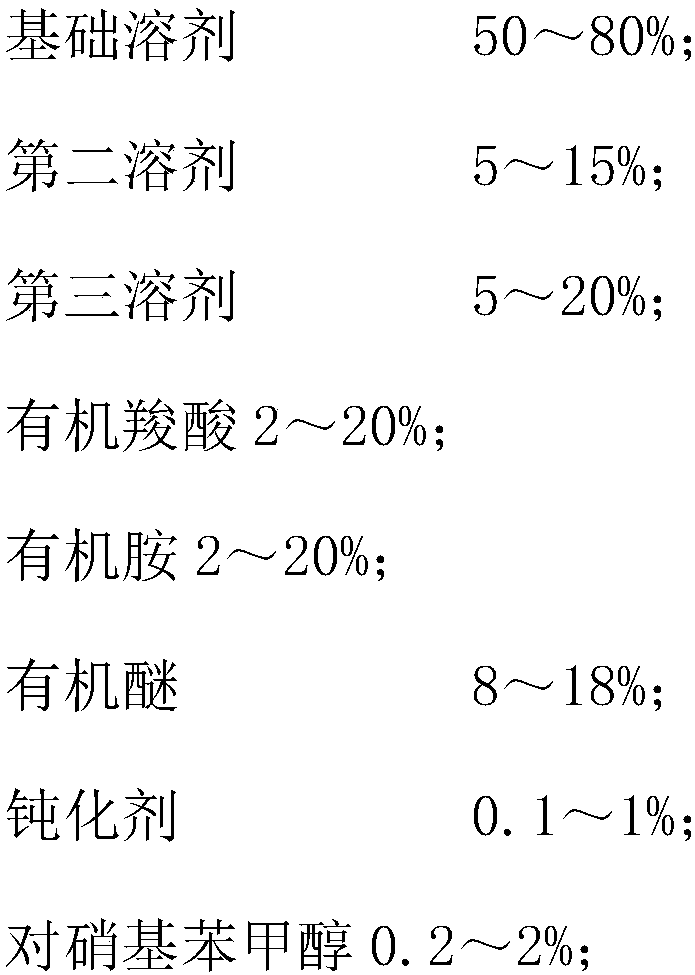

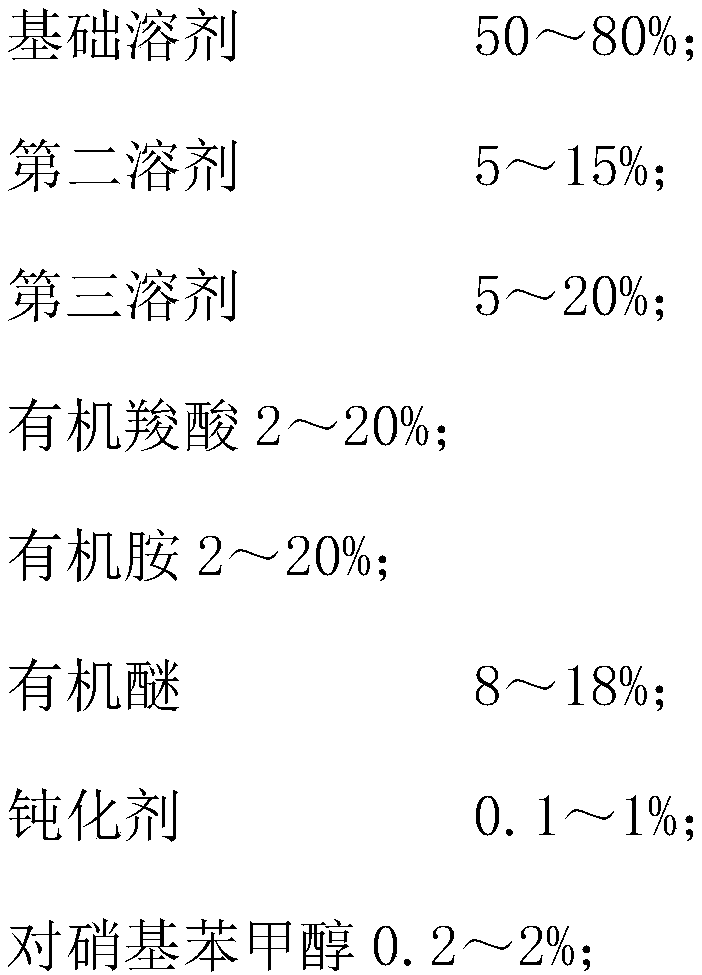

Method used

Image

Examples

Embodiment 1

[0052] Weigh by weight: 50 parts of ethylene glycol, 5.5 parts of adipic acid, 10 parts of dimethyl sulfoxide, 14 parts of N,N-dimethylformamide, 11 parts of organic amine, 8 parts of diethylene glycol ether, 0.3 parts of ammonium hypophosphite; 1.2 parts of p-nitrobenzyl alcohol.

[0053] Preparation of boron-free high-voltage (500WV) working electrolyte with good stroboscopic characteristics from the raw materials weighed above:

[0054] Step 1: Add ethylene glycol and adipic acid into the container, stir evenly and heat to 50°C; stop heating, stir until completely dissolved;

[0055] Step 2, then use a pipetting device to slowly drop in the organic amine and accelerate stirring for 30 minutes;

[0056] Step 3, adding diethylene glycol ether, hypophosphorous acid, and p-nitrobenzyl alcohol into the container successively and stirring;

[0057] Step 4, after adding the above-mentioned component materials in sequence, keep the temperature at 135°C for 150 minutes and stir; ...

Embodiment 2

[0062] Weigh by weight: 63 parts of ethylene glycol, 3 parts of suberic acid, 6 parts of N,N-dimethylformamide, 10 parts of methyl cyanide, 6 parts of organic amine, 10 parts of polyethylene glycol ether, 0.5 parts of ammonium hypophosphite; 1.5 parts of p-nitrobenzyl alcohol.

[0063] Preparation of boron-free high-voltage (500WV) working electrolyte with good stroboscopic characteristics from the raw materials weighed above:

[0064] Step 1, add ethylene glycol and suberic acid into the container, stir evenly and heat to 50°C; stop heating, stir until completely dissolved;

[0065] Step 2, then use a pipetting device to slowly drop in the organic amine and accelerate stirring for 30 minutes;

[0066] Step 3, adding polyethylene glycol ether, hypophosphorous acid, and p-nitrobenzyl alcohol into the container successively and stirring;

[0067] Step 4, after adding the above-mentioned component materials in sequence, keep the temperature at 135°C for 150 minutes and stir;

...

Embodiment 3

[0072] Weigh by weight: 57 parts of ethylene glycol, 7 parts of hydrogen azelaic acid, 6 parts of acetone, 7 parts of 4-hydroxybutyrolactone, 6 parts of organic amine, 15 parts of polyglyceryl ether, 0.8 parts of ammonium hypophosphite Parts; 1.2 parts of p-nitrobenzyl alcohol.

[0073] Preparation of boron-free high-voltage (500WV) working electrolyte with good stroboscopic characteristics from the raw materials weighed above:

[0074] Step 1, add ethylene glycol and azelaic acid hydrogen into the container, stir evenly and heat to 50°C; stop heating, stir until completely dissolved;

[0075] Step 2, then use a pipetting device to slowly drop in the organic amine and accelerate stirring for 30 minutes;

[0076] Step 3, adding polyglyceryl ether, hypophosphorous acid, and p-nitrobenzyl alcohol into the container in sequence and stirring;

[0077] Step 4, after adding the above-mentioned component materials in sequence, keep the temperature at 135°C for 150 minutes and stir; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com