Cathode lithium protection lithium-sulfur electrolyte and preparation method thereof

An electrolyte and lithium-sulfur technology, which is applied in the lithium-sulfur electrolyte protected by negative electrode lithium and its preparation field, can solve the problems that the capacity of lithium-sulfur batteries does not play a substantial role, the battery cycle performance decreases, and the role of additives is limited. Improved capacity retention and cycle stability, improved battery safety factor, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

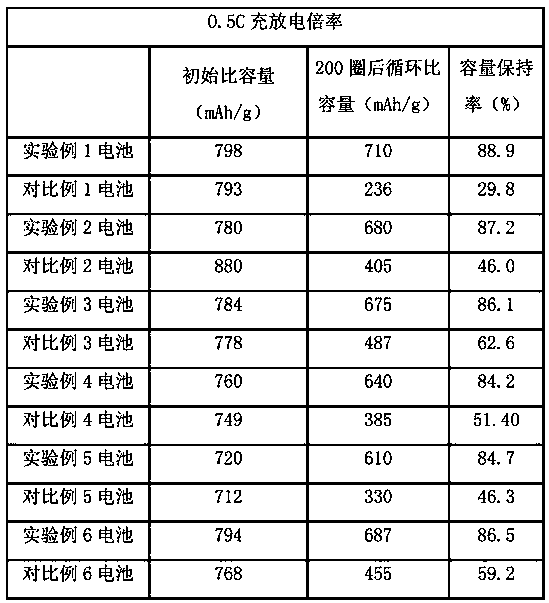

Examples

preparation example Construction

[0015] A method for preparing a lithium-sulfur electrolyte protected by negative electrode lithium includes the following steps:

[0016] Step 1: Make the inside of the glove box in an argon atmosphere, and the water and oxygen content inside does not exceed the standard condition, mix the two solvents evenly to make an ether solvent; the water content value is less than 1ppm, and the oxygen content value is less than 1ppm;

[0017] Step 2: Take the lithium salt, slowly add the lithium salt to the ether solvent described in Step 1, and mix uniformly to form a mixed solution; the mass fraction of the lithium salt in the mixed solution is 10-30%;

[0018] Step 3: Take the transition metal nitrate, and place the transition metal nitrate in a vacuum drying box for drying treatment; the temperature in the vacuum drying box is: 180°C, the drying time is: 24h; high purity is used every 2h Argon replaces the gas in the vacuum drying oven once;

[0019] Step 4: Add the crystalline water-free ...

Embodiment 1

[0022] A lithium-sulfur electrolyte for negative electrode lithium protection, comprising ether solvents, lithium salts and transition metal nitrates. The ether solvents are a mixture of two solvents, and the first solvent is 1,3-dioxolane , The second solvent is ethylene glycol dimethyl ether; the lithium salt is LiTFSi; the transition metal nitrate is La(NO 3 ) 3 ·9H 2 O.

[0023] A method for preparing a lithium-sulfur electrolyte protected by negative electrode lithium includes the following steps:

[0024] Step 1: Make the inside of the glove box in an argon atmosphere, and under the condition that the internal water and oxygen content does not exceed the standard, take 1,3-dioxolane and ethylene glycol dimethyl ether and mix them uniformly to make an ether solvent; The water content value is less than 1 ppm, and the oxygen content value is less than 1 ppm;

[0025] Step 2: Take LiTFSi, slowly add LiTFSi to the ether solvent described in Step 1, and mix them evenly to form a mi...

Embodiment 2

[0029] A lithium-sulfur electrolyte for protection of negative electrode lithium, comprising ether solvents, lithium salts and transition metal nitrates. The ether solvents are a mixture of two solvents. The first solvent is 1,4-dioxane , The second solvent is diethylene glycol dimethyl ether; the lithium salt is LiFSi; the transition metal nitrate is La(NO 3 ) 3 ·9H 2 O.

[0030] A method for preparing a lithium-sulfur electrolyte protected by negative electrode lithium includes the following steps:

[0031] Step 1: Make the inside of the glove box in an argon atmosphere, and under the condition that the internal water and oxygen content does not exceed the standard, take 1,4-dioxane and diethylene glycol dimethyl ether and mix evenly to make an ether solvent ; The water content value is less than 1ppm, and the oxygen content value is less than 1ppm;

[0032] Step 2: Take LiFSi, slowly add LiFSi to the ether solvent described in Step 1, and mix uniformly to make a mixed solution; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com