SBS (styrene butadiene styrene block copolymer) adhesive and preparation method thereof

An adhesive and antioxidant technology, applied in the directions of adhesives, adhesive types, rosin adhesives, etc., can solve the problems of unsatisfactory, poor elongation at break and tensile shear strength, and inability to improve yellowing resistance. , to achieve good yellowing resistance, improve elongation at break and tensile shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are provided below to specifically describe the present invention. It is necessary to point out that the following examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention. Some non-essential improvements or adjustments made by the embodiments to the present invention still belong to the protection scope of the present invention.

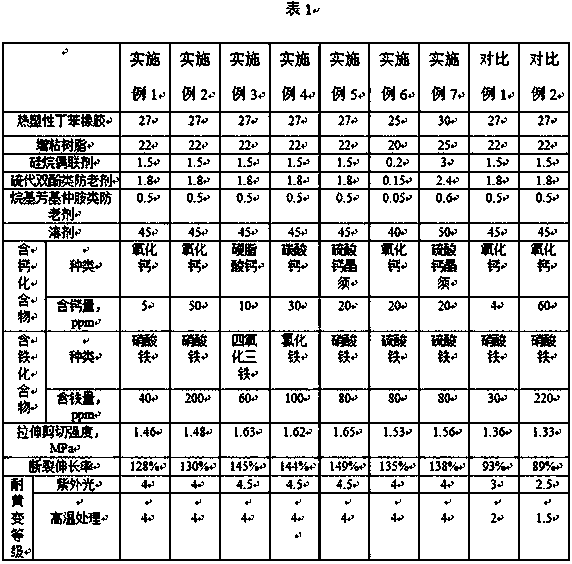

[0028] The preparation of SBS adhesive in embodiment 1-7 and comparative example 1-2:

[0029] According to the formula in Table 1, first add the solvent to the reaction kettle with a temperature of 14-20°C, and then add thermoplastic styrene-butadiene rubber, tackifying resin, silane coupling agent, calcium-containing compound, iron-containing compound and anti-aging agent to the reaction kettle in sequence And stir for 2-3 hours until uniform, then pour out and filter to obtain the SBS adhesive.

[0030] Wherein, the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com