System device for liquid deoxidization and application

A system device and liquid supply technology, which is applied in the direction of liquid degassing, degassed water/sewage treatment, separation methods, etc., can solve the problems of complex pipelines, large space occupied by equipment, and liquid leakage, so as to simplify the process, save space, The effect of controllable operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

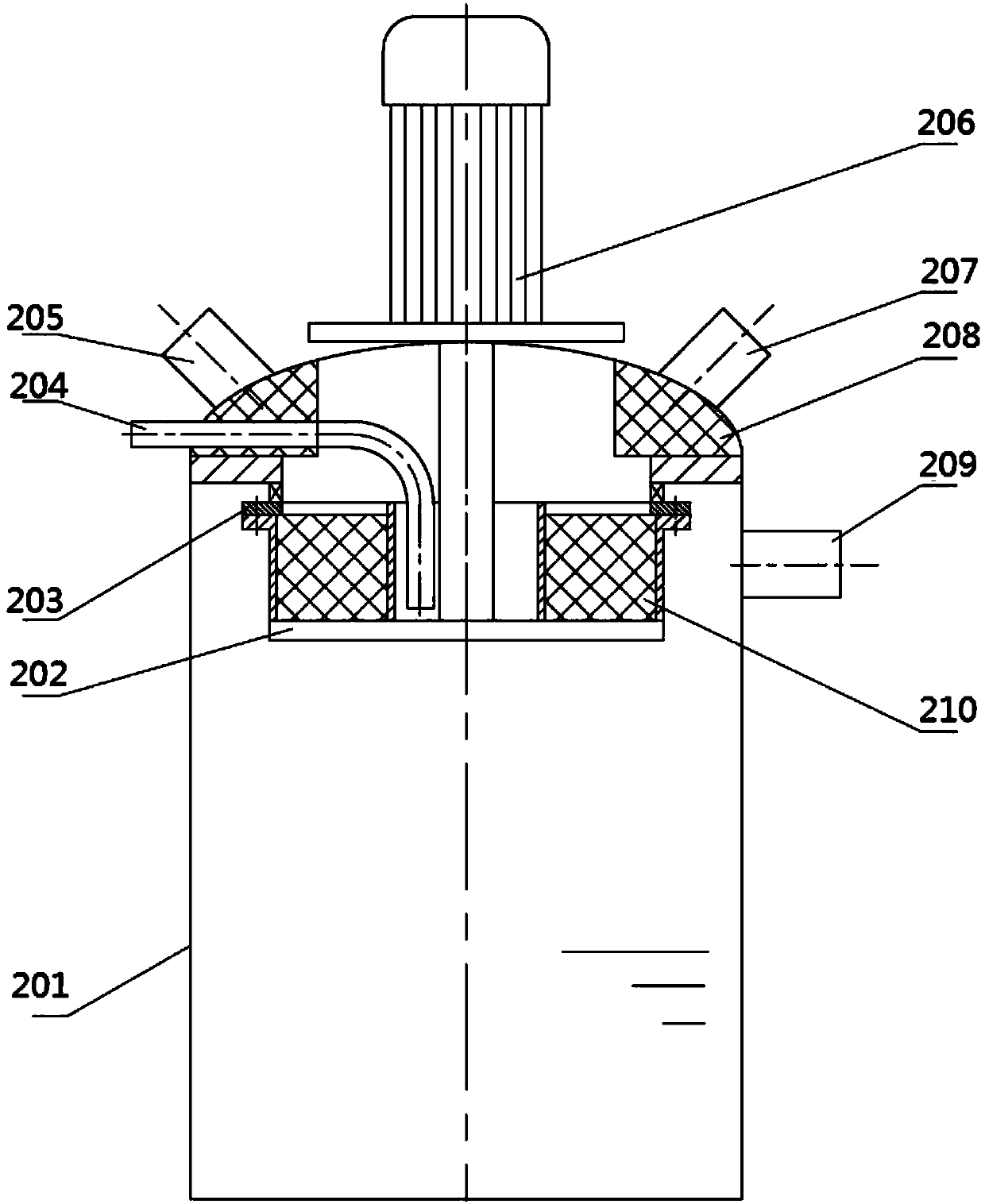

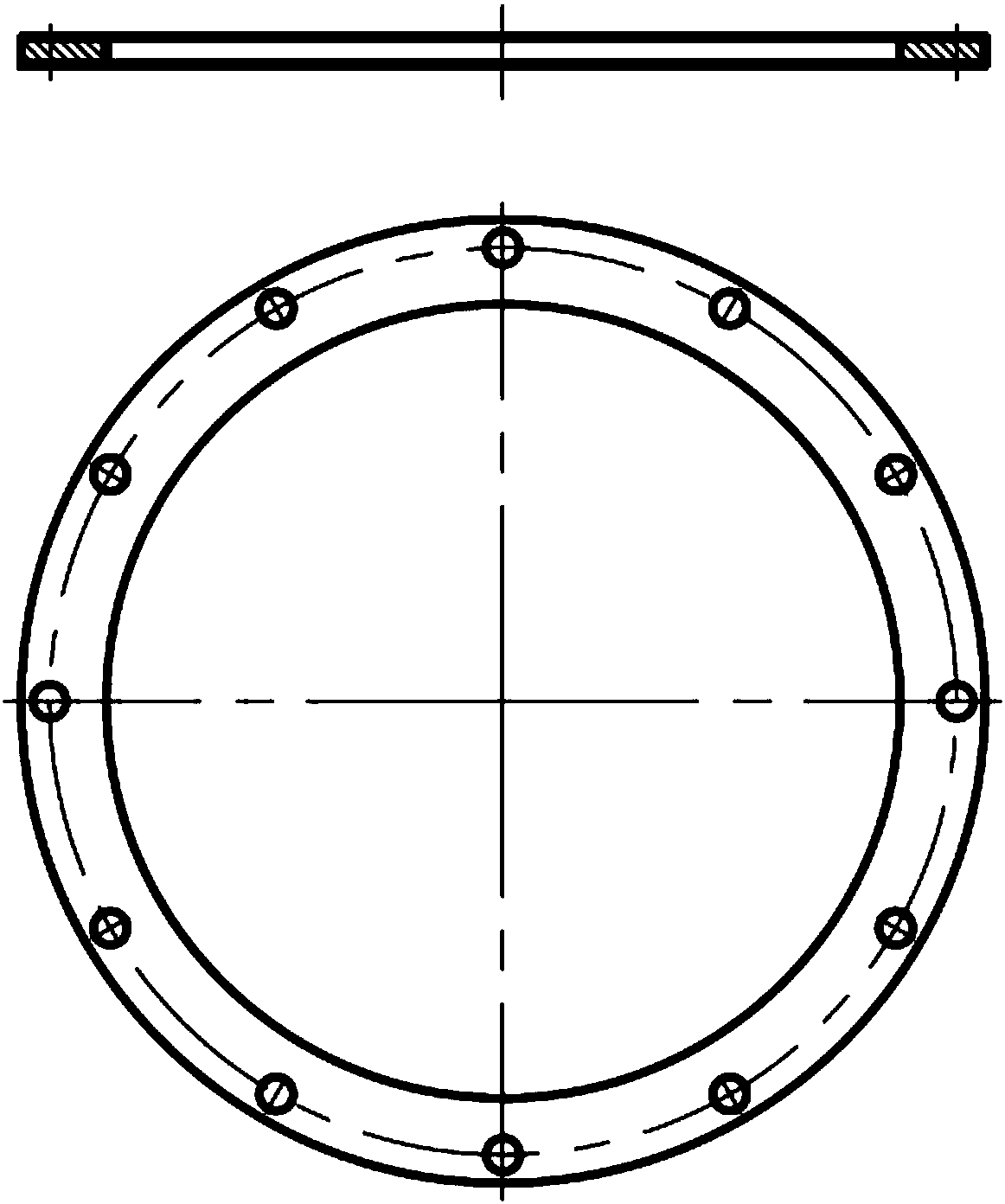

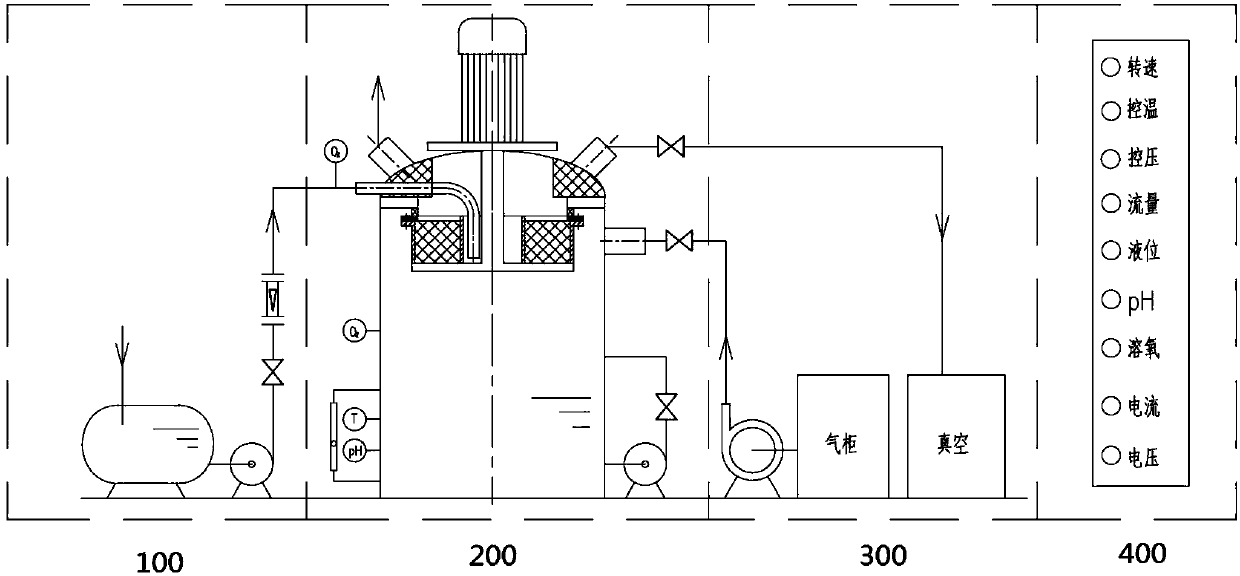

[0052] The sectional view in the liquid phase deoxidation module in the system device of the present invention is as follows figure 1 As shown, the section and top view of the rotor cover of the supergravity equipment are as follows figure 2 shown. image 3 A schematic diagram of the device of the system of the present invention is shown.

[0053] exist figure 1 , the meanings of the numbers in each part are: 201 liquid storage tank, 202 rotor, 203 rotor cover, 204 liquid inlet, 205 gas outlet, 206 motor, 207 vacuum interface, 208 demister, 209 gas inlet, 210 packing . exist image 3 , the meanings of the numbers in each part are: 100 liquid supply module, 200 deoxygenation module, 300 auxiliary module, 400 intelligent control module.

[0054] combine figure 1 and figure 2 It can be seen that the deoxygenation module of the present invention includes: the liquid storage tank 201 and the shell of the supergravity equipment are integrated, and the supergravity equipment...

Embodiment 2

[0058] In China, oilfield water injection is an important part of the production system of oil and gas fields. Due to the large demand for oxygen-poor water, vacuum deoxygenation is generally selected. The present invention provides the application of a liquid deoxygenation system device in oilfield water injection, and its process is as follows image 3 As shown, the specific steps are as follows:

[0059] (1) Seawater enters the raw material tank after being filtered upstream, and the liquid in the raw material liquid storage tank is pumped into the device of the deoxygenation module through the liquid. The treatment liquid volume of the gravity device should be less than or equal to 5000m 3 / d.

[0060] (2) Close the gas supply system and gas outlet. The vacuum pump adopts a water ring vacuum pump. Open and adjust the suction capacity of the vacuum pump to 200m 3 / h, the gas-liquid mixture discharged from the pump enters the gas-liquid separation tank, after the gas is s...

Embodiment 3

[0064] Beer is a popular beverage. However, the presence of oxygen in beer will lead to biological oxidation reactions such as proteins in beer, resulting in problems such as short shelf life and bad taste. The invention provides an application of a liquid deoxygenation system device in the preparation of deoxygenated water for high-concentration dilution in beer production, and its process is as follows image 3 As shown, the specific steps are as follows:

[0065] (1) The sterilized pure water is stored in the raw material tank, and enters the deoxygenation device through a liquid pump, and the liquid inlet pipeline is adjusted to 10m by a pressure regulating valve and a liquid flow meter 3 / h.

[0066] (2) Turn on the gas lift system and vacuum system at the same time, close the gas outlet in the deoxidation device, turn on the vacuum pump and regulating valve, turn on the gas pump and valve of carbon dioxide, and the reserve gas in the gas cabinet is a sufficient amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com