Heating tool and heating method for thermal expansion pipe of plastic pipe

A technology for heating tools and plastic pipes, which is applied in the field of heat expansion and forming of plastic pipes. It can solve the problems of thin and easily damaged pipe walls, uneven thickness of pipe walls, and uneven heating, so as to improve safety and reliability, and work The environment is comfortable and safe, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

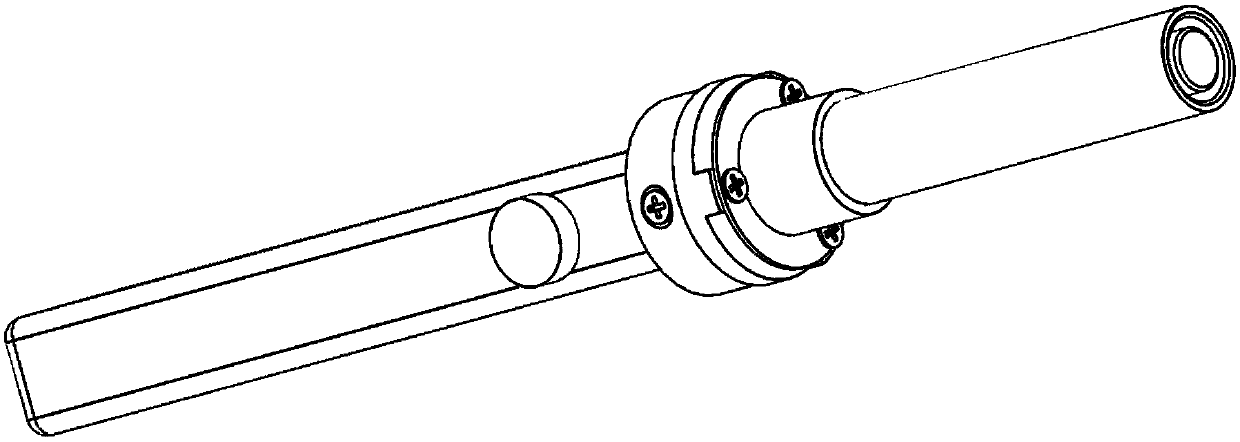

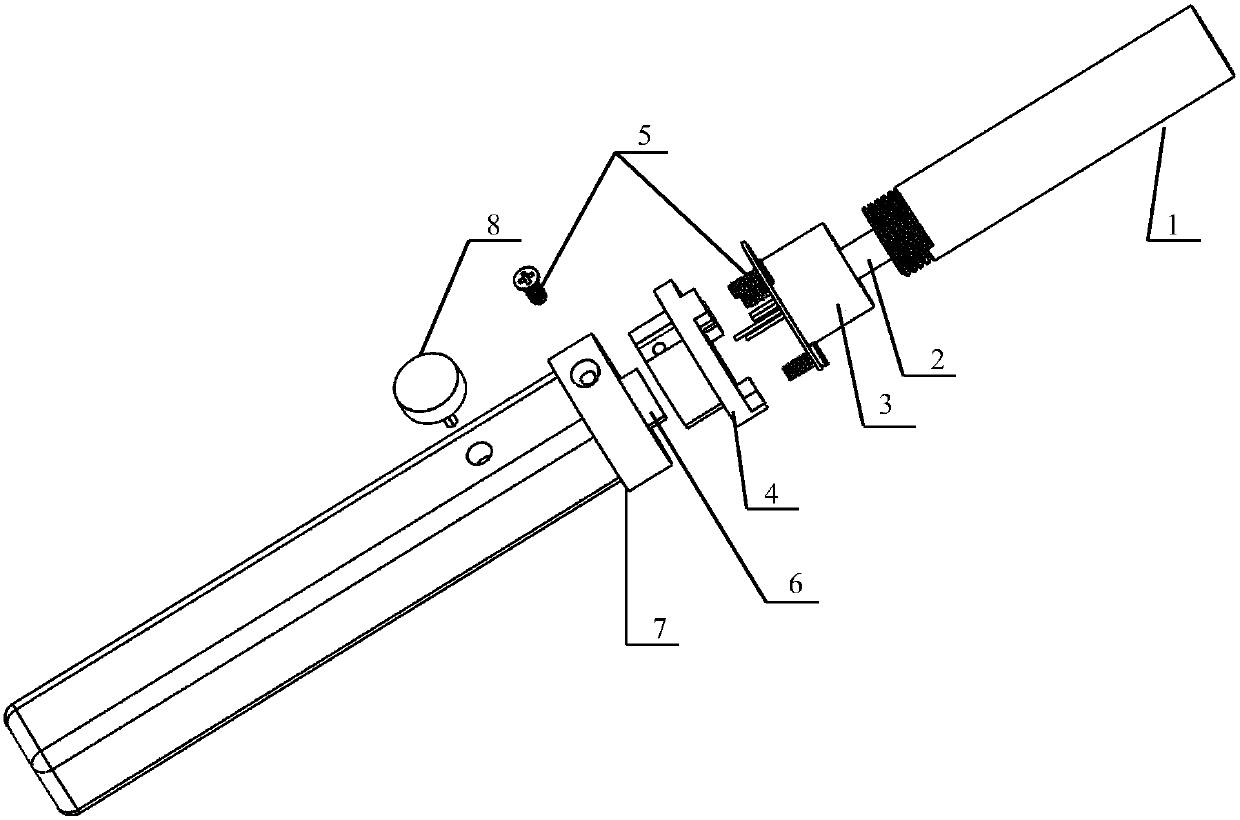

[0026] Embodiment 1: as figure 1 , 2 As shown, the heating tool for thermal expansion of plastic pipes includes: heat conduction element 1, electric heating element 2, fixing head 3, fixing seat 4, self-tapping screw 5, circuit board 6, handle 7, temperature adjustment knob 8, power supply cord and plug.

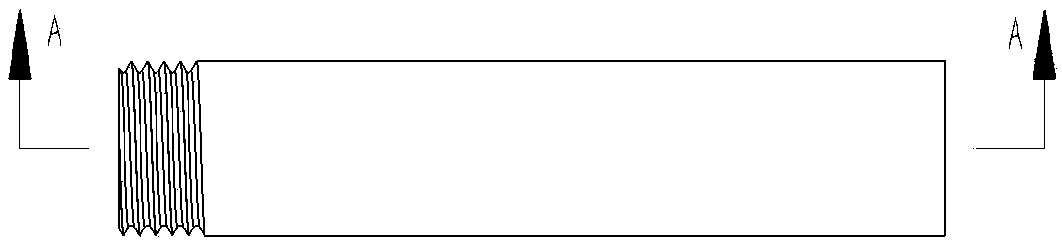

[0027] The heat conduction element 1 is made of image 3 In the shape shown, the heat conduction element 1 is made of copper or other materials with high thermal conductivity, the purpose of which is to have a good temperature consistency of the heat conduction element itself, Figure 3a and Figure 3b As shown, one end of the heat conduction element 1 is threaded 1.1 for screwing into the fixed head 3, and the inner wall of the corresponding fixed head 3 has an internal thread matching the external thread, and the outer ring 1.2 of the heat conduction element 1 and the inner cylinder 1.3 There is an annular gap 1.4 between them, and a heating hole 1.5 is arranged in the...

Embodiment 2

[0035] Embodiment 2: It is basically the same as the above embodiment 1, the difference is that the heat conduction element 1 is made into the second form, such as Figure 10 and Figure 10a In the shape shown, the electric heating element 2 is inserted into the heating hole 10.1 of the heat conduction element 1 to heat from the inside; the outer cylinder 10.2 of the heat conduction element is inserted into the plastic pipe hole to be expanded. This embodiment adopts the internal heating method, and the outer wall of the heat conduction element and The inner wall of the plastic pipe to be expanded is in contact, and the plastic pipe to be expanded is heated through heat conduction and short-distance heat radiation.

Embodiment 3

[0036] Embodiment 3: It is basically the same as the above embodiment 1, the difference is that the heat conduction element 1 is made into a third form, such as Figure 11 and Figure 11a In the shape shown, the electric heating element 2 is inserted into the heating hole 11.1 of the heat conduction element 1 to heat from the inside; the cylinder 11.2 at the front end of the heat conduction element is relatively thin, which is suitable for expanding small-diameter plastic pipes, and the cylinder 11.2 of the heat conduction element is inserted into the pipe to be expanded In the hole of the plastic tube, its outer wall is in contact with the inner wall of the plastic tube to be expanded, and the plastic tube to be expanded is heated by heat conduction and short-distance heat radiation, and the inner wall heating method is also adopted.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap