Low-viscosity display screen flame-retardant surface mounting pouring sealant

A technology of display screen and potting glue, which is applied in the field of potting glue, can solve problems such as insufficient viscosity, poor fluidity, and small stress, and achieve good flame retardant effect, good insulation performance, and low oil absorption value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

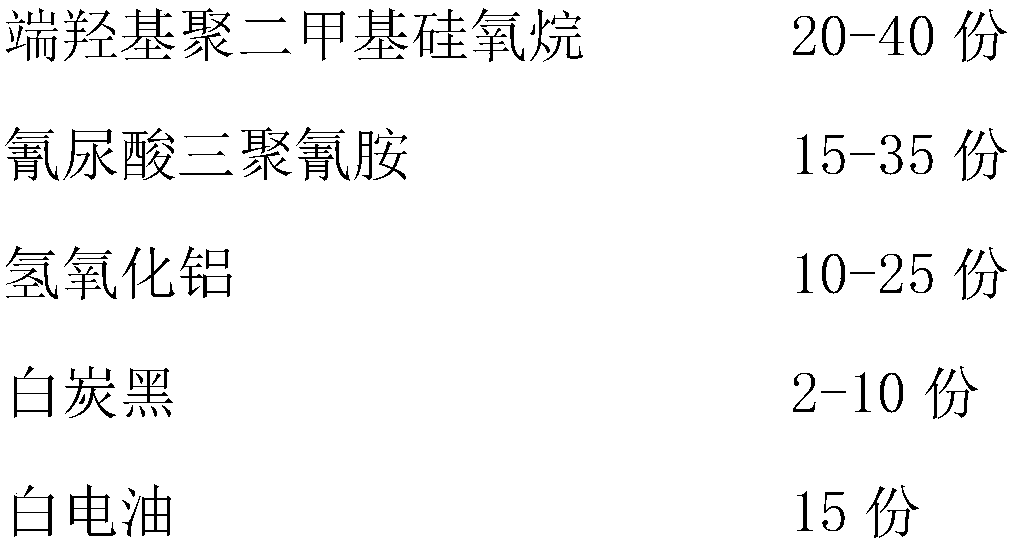

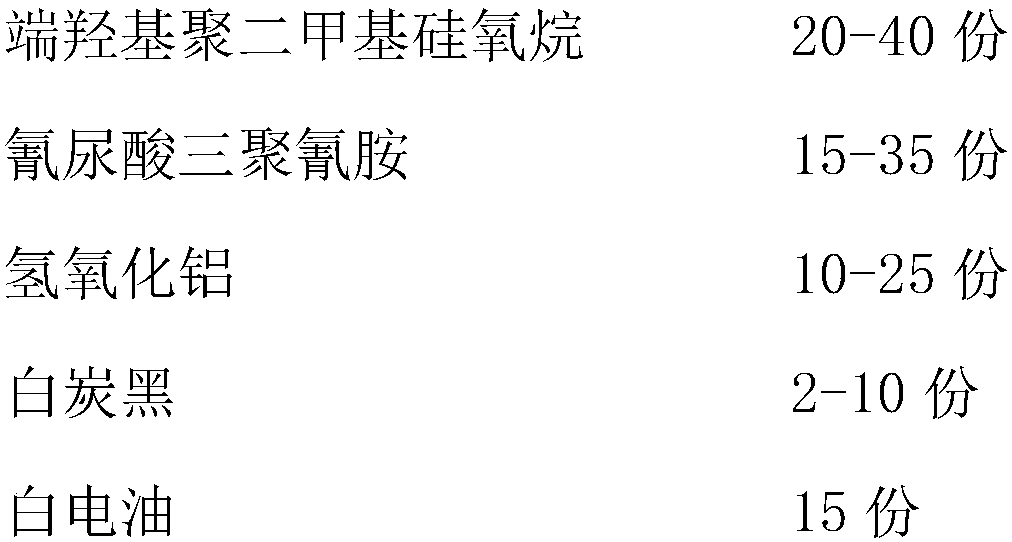

Embodiment 1

[0017] Put 30g of hydroxyl-terminated polydimethylsiloxane, 25g of melamine cyanurate, 17.5g of aluminum hydroxide, and 6g of white carbon black into the reaction kettle with agitator in sequence, and start high-speed stirring by feeding nitrogen gas at room temperature , the stirring speed is 1200 rpm, and the stirring time is 2 hours. After the high-speed stirring is completed, the stirring material in the reactor is cooled to room temperature, and 15g of white electric oil is put in, and the low-speed stirring is carried out again. After stirring evenly, use a 120-mesh filter to filter out material, to obtain the A component; in the reaction kettle with a stirrer, 3 g of γ-aminopropyltriethoxysilane, 3 g of tetraethyl orthosilicate, and 0.5 g of dibutyltin dilaurate are sequentially put into the reactor, Introduce nitrogen at room temperature and start stirring at a low speed. After stirring evenly, the B component is obtained; before the A component and the B component are ...

Embodiment 2

[0019] 40g of hydroxyl-terminated polydimethylsiloxane, 35g of melamine cyanurate, 25g of aluminum hydroxide, and 15g of white carbon black were sequentially put into a reaction kettle with a stirrer, and nitrogen gas was introduced at room temperature to start high-speed stirring. The stirring speed is 1200 r / min, and the stirring time is 2 hours. After the high-speed stirring is completed, the stirring material in the reactor is cooled to room temperature, and 15g of white electric oil is put in, and the low-speed stirring is carried out again. After stirring evenly, use a 120-mesh filter to filter the material. , to obtain the A component; put 5 g of γ-aminopropyltriethoxysilane, 5 g of ethyl orthosilicate, and 1 g of dibutyltin dilaurate into a reaction kettle with a stirrer in sequence, at room temperature Under nitrogen, start stirring at a low speed. After stirring evenly, the B component can be obtained; before the A component and the B component are mixed, the A compon...

Embodiment 3

[0021] Add 20 g of hydroxyl-terminated polydimethylsiloxane, 15 g of melamine cyanurate, 10 g of aluminum hydroxide, and 2 g of white carbon black in sequence into a reaction kettle with a stirrer, and start high-speed stirring by feeding nitrogen gas at room temperature. The stirring speed is 1200 r / min, and the stirring time is 2 hours. After the high-speed stirring is completed, the stirring material in the reactor is cooled to room temperature, and 15g of white electric oil is put in, and the low-speed stirring is carried out again. After stirring evenly, use a 120-mesh filter to filter the material. , to obtain the A component; put 1 g of γ-aminopropyltriethoxysilane, 1 g of ethyl orthosilicate, and 0 g of dibutyltin dilaurate into a reaction kettle with a stirrer in sequence, at room temperature Under nitrogen, start stirring at a low speed. After stirring evenly, the B component can be obtained; before the A component and the B component are mixed, the A component needs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com