Grass carp feed and preparation method thereof

A grass carp feed and raw material technology, applied in the field of feed, can solve the problem of high feed cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

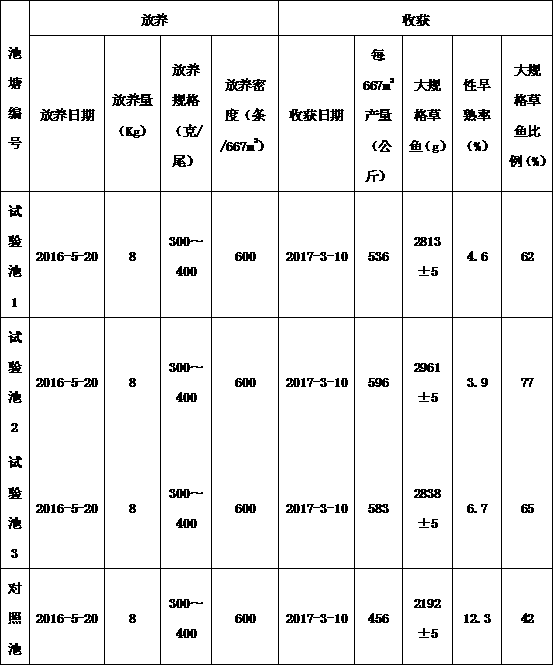

Examples

Embodiment 1

[0043] A grass carp feed, which comprises the following raw materials in parts by weight: bagasse 100, fruit waste 30, apple snail 20, superphosphate 10, shrimp shell 10, calcium carbonate 10, sea salt 10, molasses 10, earthworm powder 8, compound 8 enzymes, 6 additives, 4 compound amino acids, 1 trace element.

[0044] The compound enzyme includes the following components in parts by weight: cellulase 3, trypsin 8, pectinase 6, β-glucanase 10; each component is mixed and placed at 35-45°C for 40-50 minutes. The complex enzyme can be obtained.

[0045] Fruit waste refers to one or more mixtures of various low-grade fruits, defective fallen fruits, peels, fruit scraps or fruit cores left after fruit processing.

[0046] The weight ratio of additive ingredients includes the following raw materials: 10 grams of mannan-oligosaccharides, 25 grams of soybean lecithin, 8 grams of sodium alginate, 1 gram of saccharoterpenoids, 6 grams of dodder, 6 grams of licorice, 0.5 grams of tea ...

Embodiment 2

[0059] A grass carp feed, which comprises the following raw materials in parts by weight: bagasse 100-200, fruit waste 40, apple snail 25, superphosphate 15, shrimp shell 15, calcium carbonate 15, sea salt 15, molasses 15, earthworm powder 9 , compound enzyme 9, additive 7, compound amino acid 5, trace element 2.

[0060] The compound enzyme includes the following components in parts by weight: cellulase 4, trypsin 9, pectinase 7, β-glucanase 13; each component is mixed and placed at 35-45°C for 40-50 minutes. The complex enzyme can be obtained.

[0061] Fruit waste refers to one or more mixtures of various low-grade fruits, defective fallen fruits, peels, fruit scraps or fruit cores left after fruit processing.

[0062] The weight ratio of the additive ingredients includes the following raw materials: 13 grams of mannan oligosaccharides, 28 grams of soybean lecithin, 9 grams of sodium alginate, 2 grams of saccharoterpenoids, 7 grams of dodder, 7 grams of licorice, 1 gram of ...

Embodiment 3

[0075] A grass carp feed, which comprises the following raw materials in parts by weight: bagasse 100-200, fruit waste 50, apple snail 30, superphosphate 20, shrimp shell 20, calcium carbonate 20, sea salt 20, molasses 20, earthworm powder 10 , 10 compound enzymes, 8 additives, 6 compound amino acids, 3 trace elements.

[0076] The compound enzyme includes the following components in parts by weight: cellulase 5, trypsin 10, pectinase 8, β-glucanase 15; each component is mixed and placed at 35-45°C for 40-50 minutes. The complex enzyme can be obtained.

[0077] Fruit waste refers to one or more mixtures of various low-grade fruits, defective fallen fruits, peels, fruit scraps or fruit cores left after fruit processing.

[0078] The weight ratio of additive ingredients includes the following raw materials: 15 grams of mannan-oligosaccharides, 30 grams of soybean lecithin, 10 grams of sodium alginate, 3 grams of saccharoterpenoids, 8 grams of dodder, 8 grams of licorice, 1.5 gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com