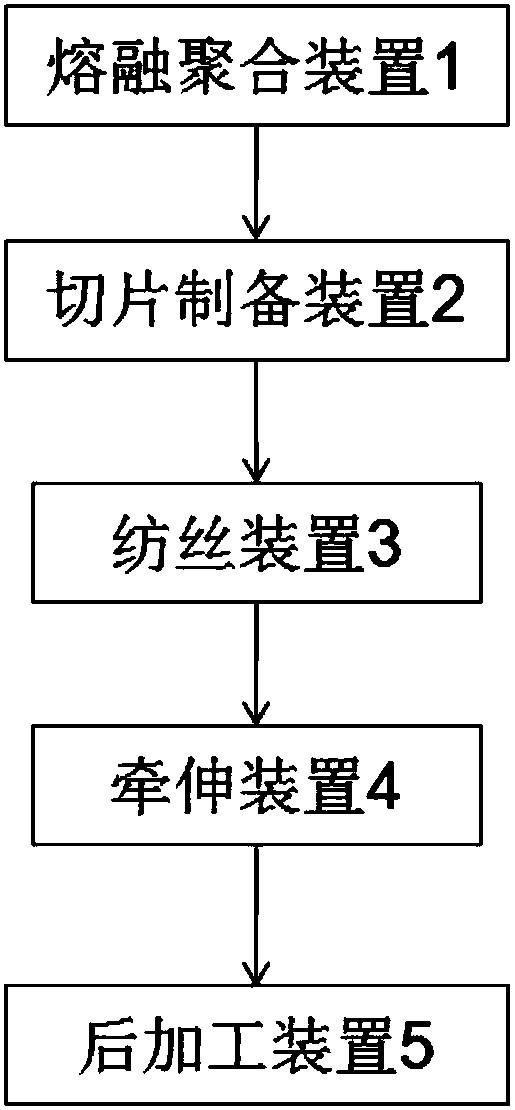

Fine-denier polyamide fiber 6 filament production line and production method thereof

A technology of fine denier nylon and a production method, applied in the field of machinery, can solve the problems of poor slice size uniformity, high impurity content, and high rejection rate, and achieve the effects of good slice size uniformity, easy cutting, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

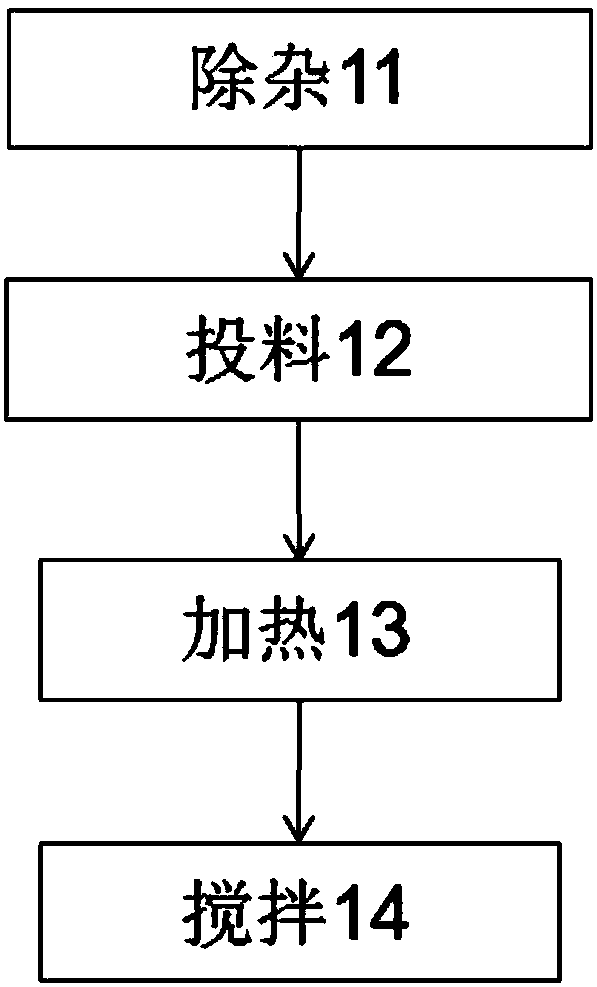

Method used

Image

Examples

Embodiment approach

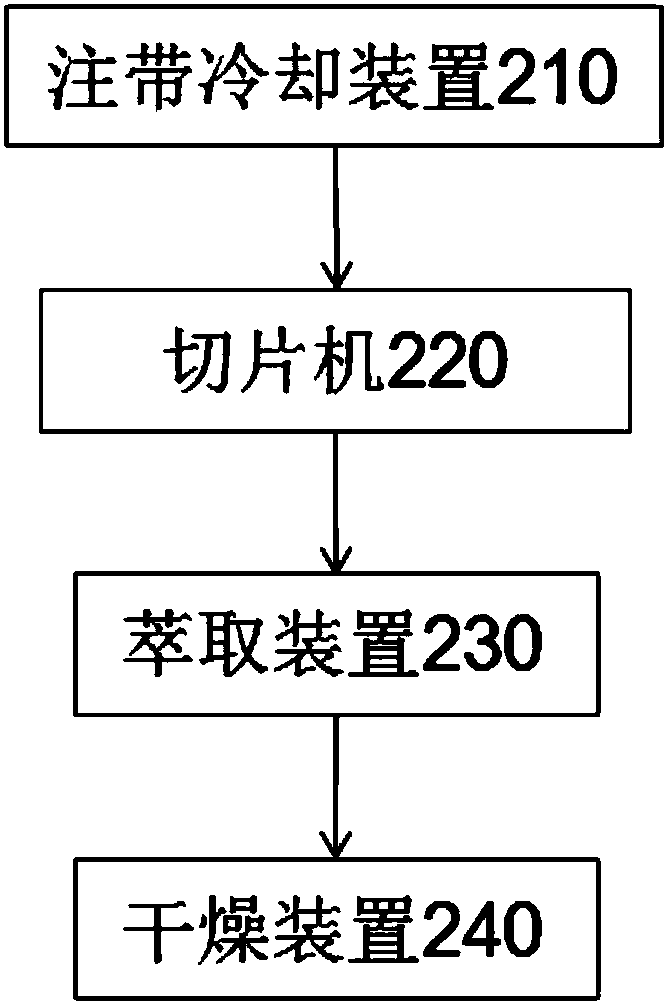

[0078] As a preferred embodiment, the pure hot water supply device 235 includes a water storage tank 212, a second delivery pump 213, and a second filter 214, and the water inlet of the water storage tank 212 is connected to the water outlet of the centrifugal separation device 236 , the water outlet of the water storage tank 212 is connected to the water inlet of the second delivery pump 213, the water inlet of the second filter 214 is connected to the water outlet of the second delivery pump 214, and the water outlet of the second filter 214 It is connected with the bottom of the extraction tower 232.

[0079] As a preferred embodiment, the lower circulation device 234 of the extraction tower includes a second heater 211, the inlet of the second heater 211 is connected to the side near the bottom of the extraction tower 232, and the outlet of the second heater 211 is It is connected with the inlet of the second filter 214 , and the water outlet of the second filter 214 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com