Waterproof shoe material and preparation method thereof

A technology for waterproof shoes and raw materials, applied in footwear, applications, clothing, etc., can solve the problems of complex production process, high labor cost, and time-consuming consumables, and achieve uniform texture, full toughness, and improve the effect of shoe material quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

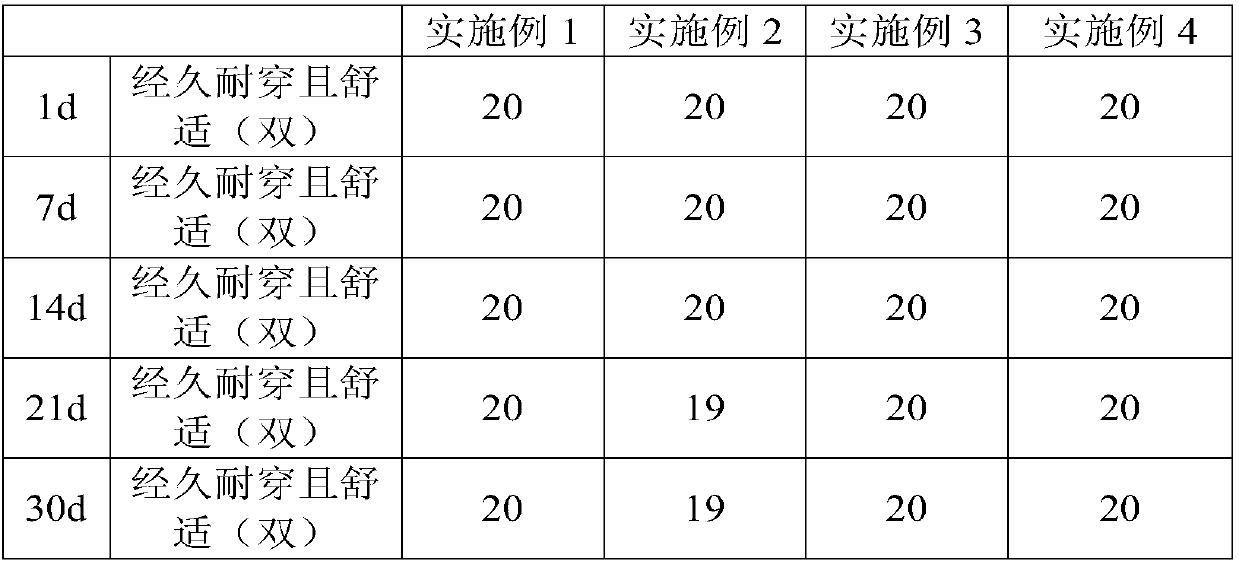

Examples

Embodiment 1

[0036] A kind of waterproof shoe material

[0037] Raw material and ingredient composition: (unit: g)

[0038]300g styrene-type thermoplastic elastomer, 100g polyurethane resin, 150g polypropylene, 80g glass fiber, 100g white mineral oil, 100g nano silicon oxide, 50g methyl p-hydroxybenzoate, 10g benzyl alcohol, 50g liquid paraffin, silane coupling agent 50g, plasticizer 30g, anti-impact agent 40g.

[0039] Among the above waterproof shoe materials, the polyurethane resin is made of polyester polyol or polybutadiene diol; the plasticizer is one or a combination of p-hydroxybenzenesulfonic acid and dioctyl phthalate; the anti-impact agent is benzene One or a combination of sodium formate and talcum powder.

[0040] The styrene-type thermoplastic elastomer in the waterproof shoe material includes at least one or a combination of styrene / ethylene-butadiene / styrene block copolymer and styrene / ethylene-propylene / styrene block copolymer.

[0041] Prepared by:

[0042] Step 1, pr...

Embodiment 2

[0049] A kind of waterproof shoe material

[0050] Raw material and ingredient composition: (unit: g)

[0051] Styrene-type thermoplastic elastomer 400g, polyurethane resin 200g, polypropylene 200g, glass fiber 150g, white mineral oil 160g, nano silicon oxide 160g, methyl p-hydroxybenzoate 100g, benzyl alcohol 50g, liquid paraffin 80g, silane coupling agent 80g, plasticizer 60g, anti-impact agent 80g.

[0052] Among the above waterproof shoe materials, the polyurethane resin is made of polyester polyol or polybutadiene diol; the plasticizer is one or a combination of p-hydroxybenzenesulfonic acid and dioctyl phthalate; the anti-impact agent is benzene One or a combination of sodium formate and talcum powder.

[0053] The styrene-type thermoplastic elastomer in the waterproof shoe material includes at least one or a combination of styrene / ethylene-butadiene / styrene block copolymer and styrene / ethylene-propylene / styrene block copolymer.

[0054] Prepared by:

[0055] Step 1,...

Embodiment 3

[0062] A kind of waterproof shoe material

[0063] Raw material and ingredient composition: (unit: g)

[0064] 320g styrene-type thermoplastic elastomer, 140g polyurethane resin, 170g polypropylene, 100g glass fiber, 120g white mineral oil, 140g nano silicon oxide, 70g methyl p-hydroxybenzoate, 30g benzyl alcohol, 60g liquid paraffin, silane coupling agent 60g, plasticizer 40g, anti-impact agent 40g.

[0065] Among the above waterproof shoe materials, the polyurethane resin is made of polyester polyol or polybutadiene diol; the plasticizer is one or a combination of p-hydroxybenzenesulfonic acid and dioctyl phthalate; the anti-impact agent is benzene One or a combination of sodium formate and talcum powder.

[0066] The styrene-type thermoplastic elastomer in the waterproof shoe material includes at least one or a combination of styrene / ethylene-butadiene / styrene block copolymer and styrene / ethylene-propylene / styrene block copolymer.

[0067] Prepared by:

[0068] Step 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com