Safe and energy-saving environmental coal drying system

A coal drying and clean technology, applied in the direction of drying room/container, drying gas arrangement, non-progressive dryer, etc., to achieve the effect of improving yield, improving safety and reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

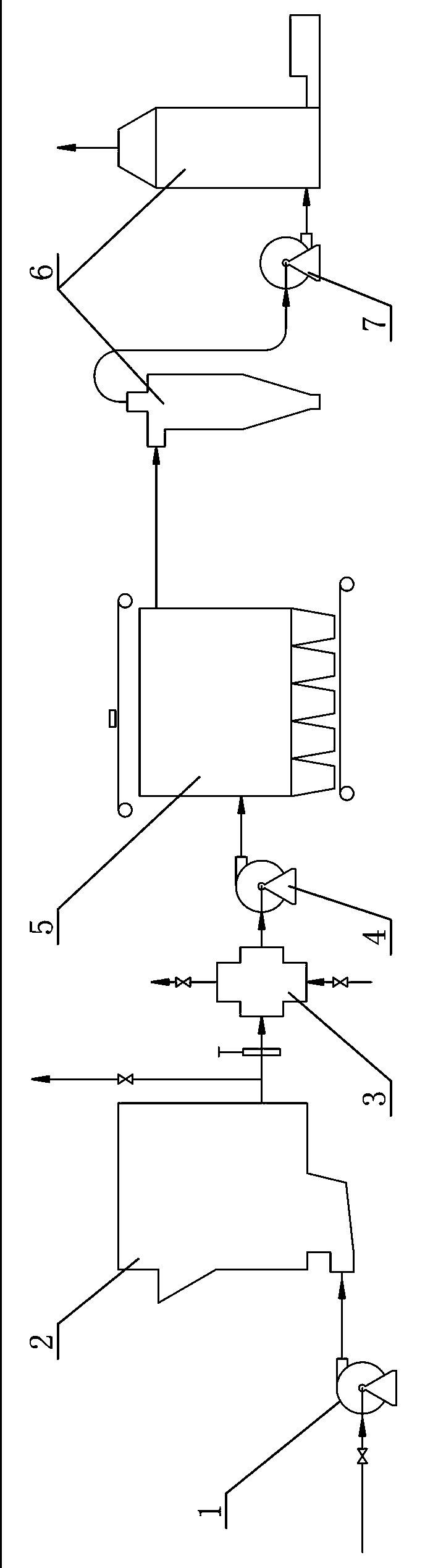

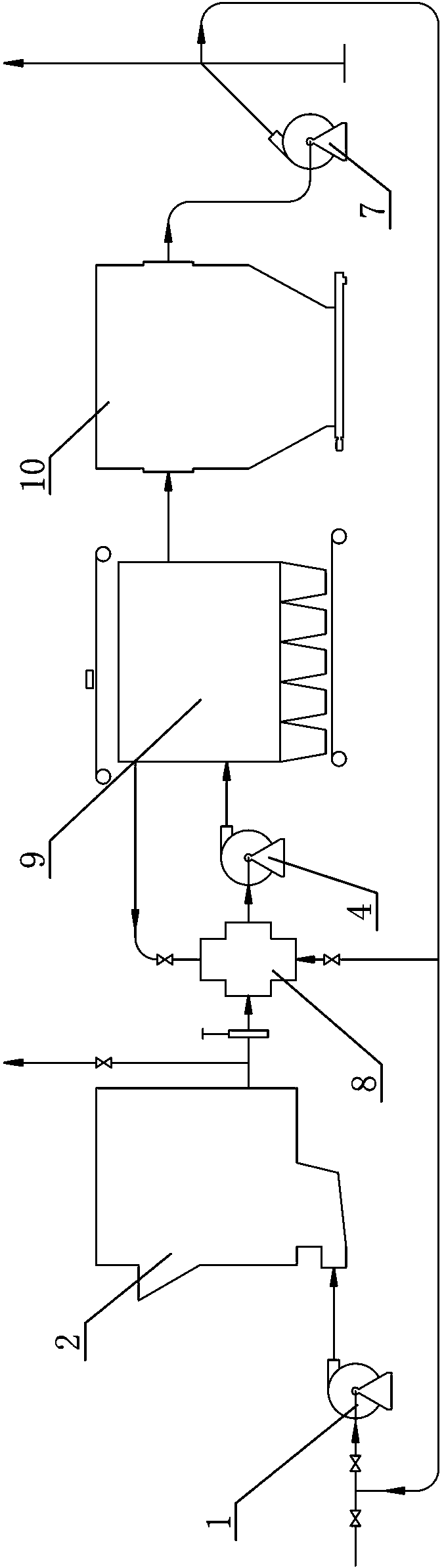

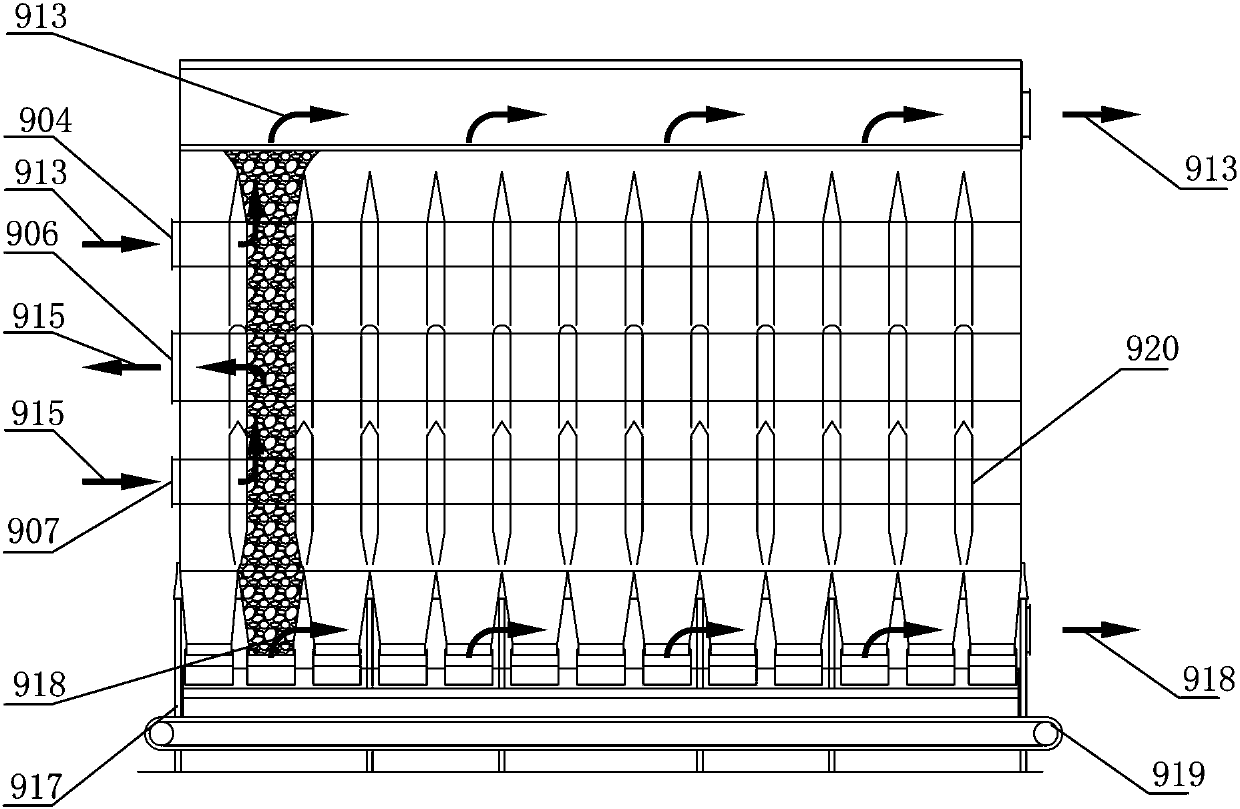

[0028] see Figure 1-9, this embodiment is a safe, energy-saving and clean briquette drying system, including fan A1, the outlet of fan A1 is connected to hot blast stove 2, part of the flue gas at the outlet of hot blast stove 2 is discharged through a safety valve, and part of it is connected to a rotary DC diffusion distribution through a high temperature valve The air device 8, the outlet of the swirling DC diffusion air distribution device 8 is connected to the fan B4, the fan B4 is connected to the internal circulation clean briquette dryer 9, the outlet of the internal circulation clean briquette dryer 9 is connected to the dry dust removal system 10, and the swirling DC diffusion Type air distributor 8 includes a cylindrical air mixing pipe 808, one end of the air mixing pipe 808 is a high-temperature flue gas inlet 803, and the other end is a mixed flue gas outlet 807, and the air mixing pipe 808 is close to the high-temperature flue gas inlet The tangential direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com