Mesoporous silica nano-drug carrier and preparation method thereof

A nano drug carrier, mesoporous silica technology, applied in the field of materials and pharmaceuticals, inorganic chemistry, can solve the problem of difficult biodegradation of mesoporous silica, achieve good structural stability, improve biodegradability, and benefit Effects of degradation and excretion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The mesoporous silica nano-drug carrier in this example is composed of calcium phosphate and silicon dioxide with a mass ratio of 1:18.5.

[0029] Preparation of Mesoporous Silica Nano-Drug Carriers:

[0030] Dissolve 0.118g of disodium hydrogen phosphate in a mixed solvent of 25mL of distilled water + 8.75mL of ammonia water + 90mL of ethanol, then add 0.047g of octadecyltrimethoxysilane, stir and mix well, then add 0.055g of ethyl orthosilicate, Next, 0.055 g of calcium chloride was added under stirring conditions, and then the entire mixed solution was stirred and reacted at 30° C. for 8 hours. After the reaction was completed, suction filtration and washing were performed to obtain calcium phosphate-doped silica nanoparticles.

[0031] Calcium phosphate-doped silica nanoparticles were dried at 40° C. for 6 hours, and then sintered at 550° C. for 6 hours to obtain mesoporous silica nanometer drug carriers.

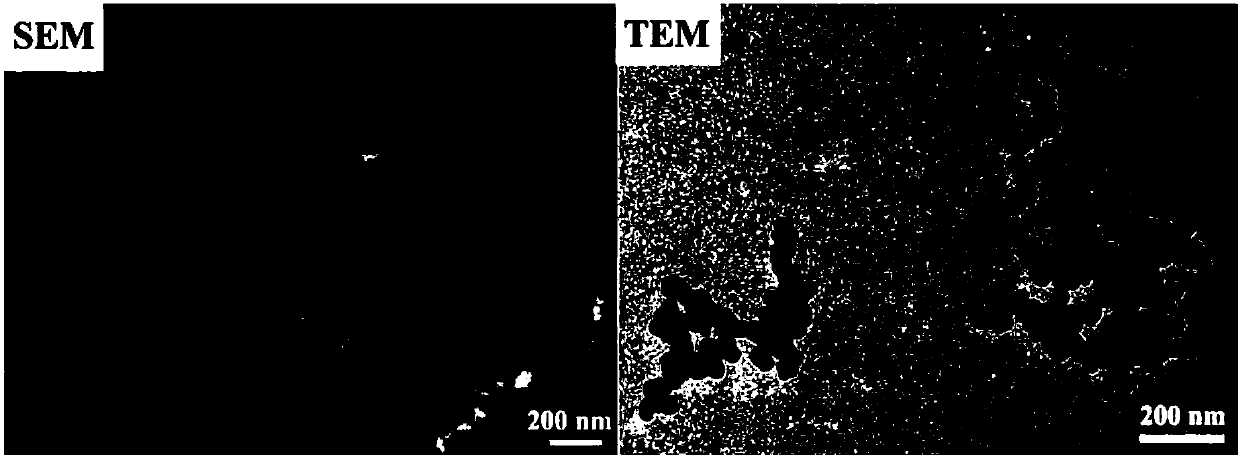

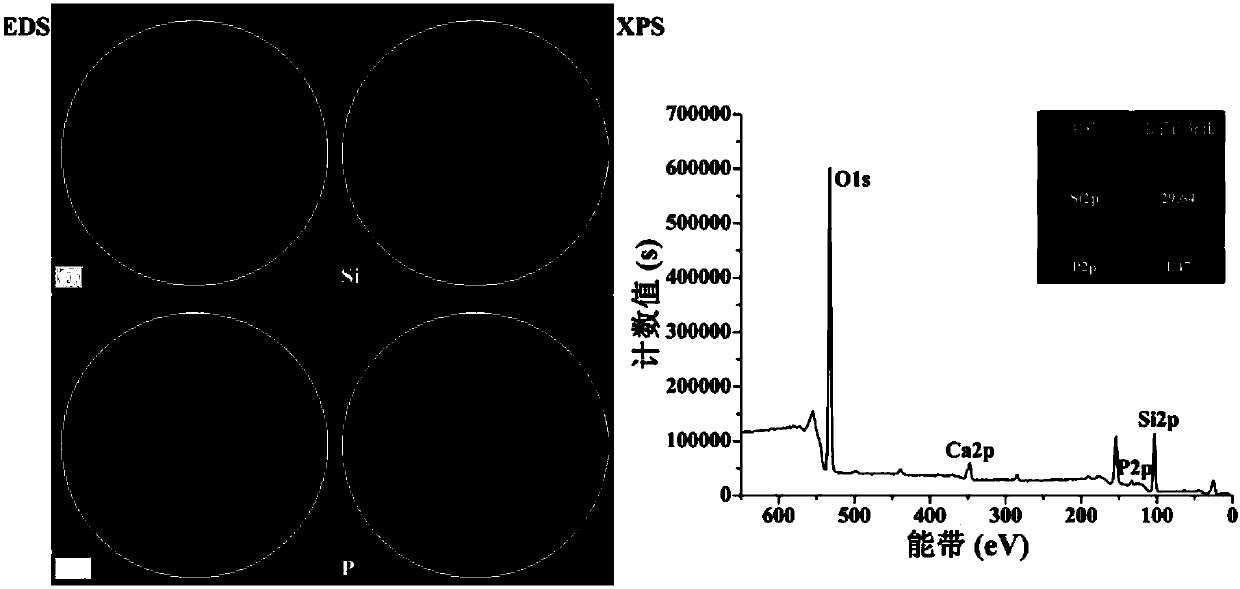

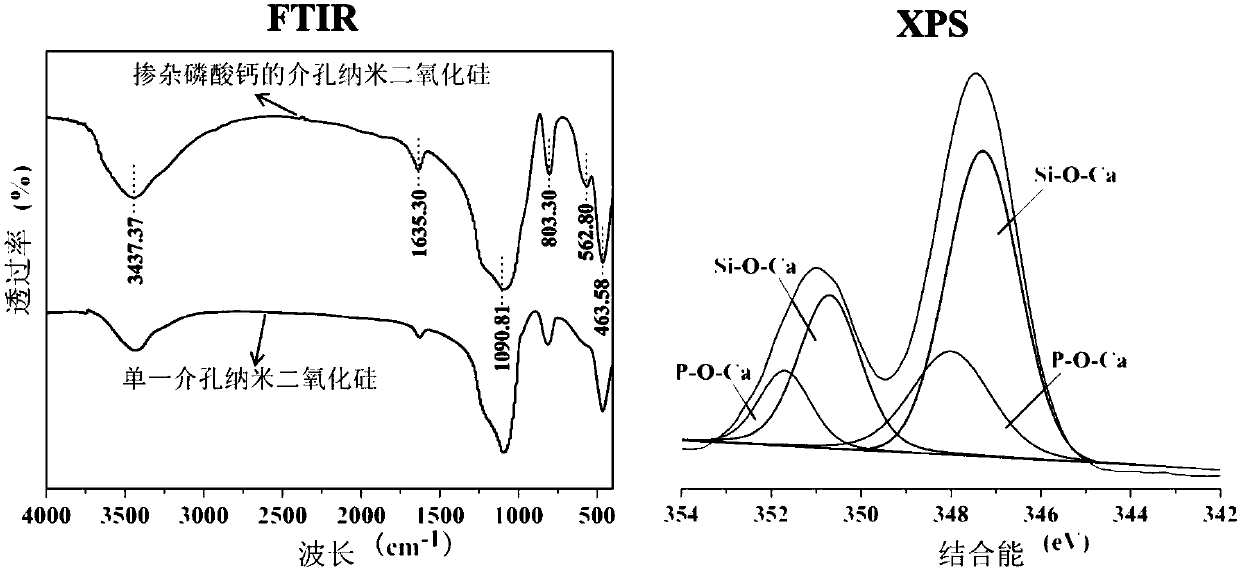

[0032] Structural characterization of mesoporous silica na...

Embodiment 2

[0042] The mesoporous silica nano-drug carrier in this example is composed of calcium phosphate and silicon dioxide with a mass ratio of 1:2.42.

[0043] Preparation of Mesoporous Silica Nano-Drug Carriers:

[0044] Dissolve 0.118g of disodium hydrogen phosphate in a mixed solvent of 100mL of distilled water + 8mL of ammonia water + 140mL of ethanol, then add 0.011g of octadecyltrimethoxysilane, stir and mix well, then add 0.042g of ethyl orthosilicate, then Add 0.177g of calcium chloride under stirring condition, then stir the whole mixed solution at 30°C for 8h, after the reaction is completed, suction filter and wash to obtain calcium phosphate doped silica nanoparticles.

[0045] Calcium phosphate-doped silica nanoparticles were dried at 30° C. for 12 hours, and then sintered at 700° C. for 5 hours to obtain mesoporous silica nanometer drug carriers.

[0046] The average particle diameter of the prepared mesoporous silica nano drug carrier is 25nm, and the average pore di...

Embodiment 3

[0048] In this example, the mesoporous silica nano drug carrier is composed of calcium phosphate and silica, and the mass ratio thereof is 1:25.8.

[0049] Preparation of Mesoporous Silica Nano-Drug Carriers:

[0050] Dissolve 0.118g of disodium hydrogen phosphate in a mixed solvent of 35mL of distilled water + 13mL of ammonia water + 80mL of ethanol, then add 1.084g of octadecyltrimethoxysilane, stir and mix well, then add 4.308g of ethyl orthosilicate, then Add 0.184g of calcium chloride under stirring condition, then stir the whole mixed solution at 30°C for 8h, after the reaction is completed, suction filter and wash to obtain calcium phosphate doped silica nanoparticles.

[0051] Calcium phosphate-doped silica nanoparticles were dried at 70° C. for 4 hours, and then sintered at 500° C. for 7 hours to obtain mesoporous silica nanometer drug carriers.

[0052] The average particle diameter of the prepared mesoporous silica nano drug carrier is 50nm, and the average pore di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com