Nitraria fruit active extract preparation method and application

A technology of extract and Nitraria fruit, which is applied in the field of preparation of Nitraria fruit active extract, can solve the problems of cumbersome steps, explosiveness, toxicity, etc., and achieve the effect of mild extraction conditions, large extraction volume and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] supercritical extraction

[0062] Supercritical fluid (supercritical fluid, SF) refers to a certain gas (liquid) or gas (liquid) mixture when the operating pressure and temperature are higher than the critical point, making its density close to liquid, while its diffusion coefficient and viscosity are close to gas , a fluid whose properties are between that of a gas and a liquid. Supercritical fluid extraction (SFE) technology is a technology that uses supercritical fluid as a solvent to extract certain effective components from solid or liquid and separate them. Carbon dioxide-supercritical fluid extraction is more suitable for the extraction of lipophilic, relatively small molecular weight substances. Here, the carbon dioxide-supercritical fluid extraction method is suitable for extracting the oil components in Nitraria.

[0063] (1) obtain the white thorn fruit raw material;

[0064] The Nitraria raw material comprises Nitraria fresh fruit, Nitraria dried fruit, N...

Embodiment 2

[0116] solvent extraction

[0117] The solvent extraction method has simple steps, can be extracted in large quantities, and is easy to carry out large-scale production and application in industry.

[0118] (1) obtain the white thorn fruit raw material;

[0119] The used Nitraria raw material of solvent extraction method is identical with the used Nitraria raw material of the supercritical extraction method in the last embodiment,

[0120] (2) In the extraction equipment, the raw material of Nitraria japonica and 65% ethanol are stirred and extracted at a temperature of -55°C;

[0121] In order to achieve a better extraction effect, at least one of the following extraction conditions can also be optimized:

[0122] (2.1) Adjust the mass volume ratio of Nitraria japonica raw material and 65% ethanol, preferably any value in 1:3~5;

[0123] (2.2) Select an appropriate stirring and extraction time, preferably 1 to 2 hours for extraction;

[0124] (2.3) Perform repeated extrac...

Embodiment 3

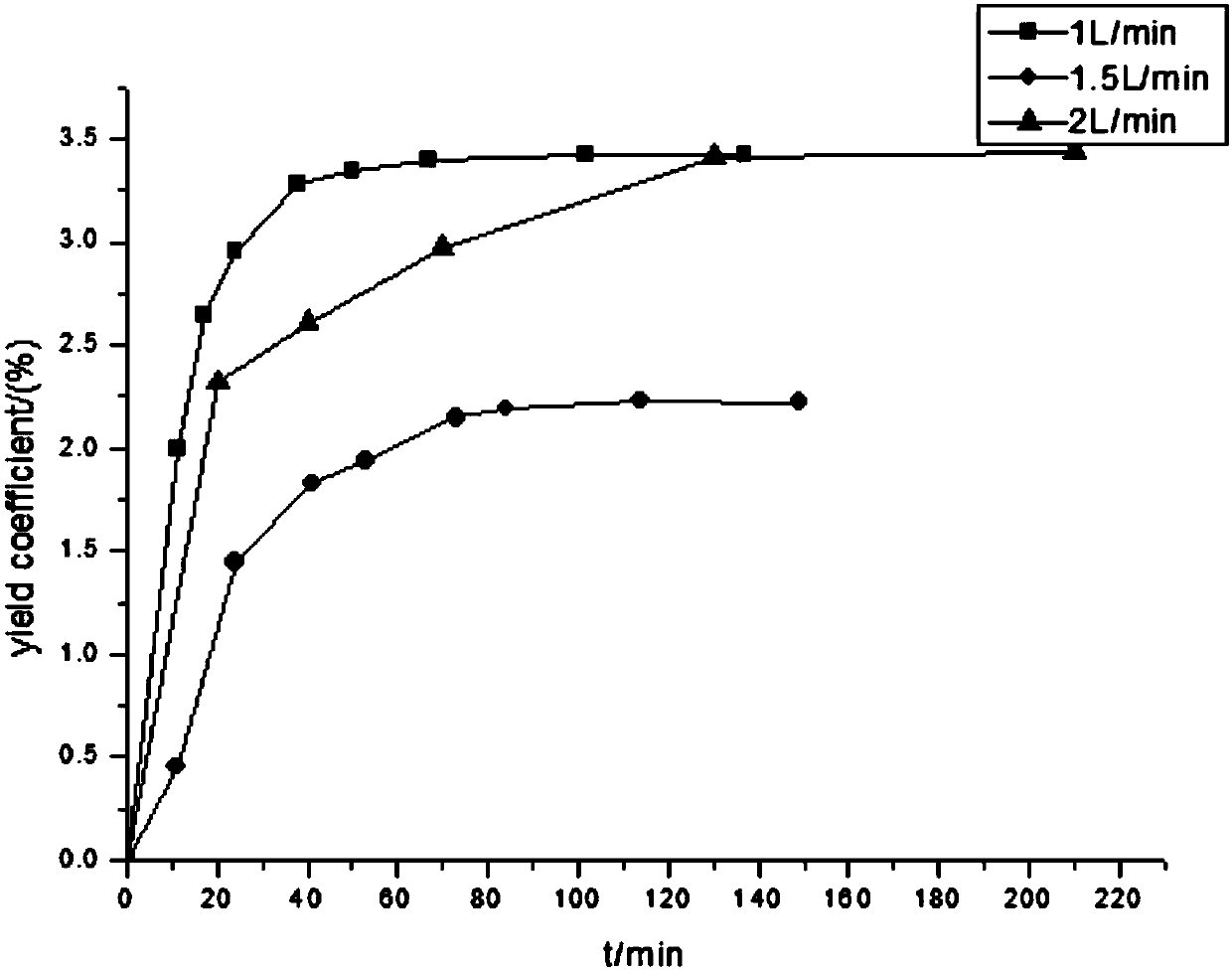

[0140] Comparison of the Yield and Content of Active Components in Nitraria

[0141] Based on the supercritical extraction method described in Example 1, the active extract of Nitraria japonica raw materials was extracted one by one according to the conditions shown in Table 8, and the corresponding yield, red pigment content and total polyphenol content were obtained.

[0142] The results show that in the range of better extraction conditions, when the degreasing raffinate with higher oil removal degree is extracted again, the product yield, red pigment content and total polyphenol content are all higher; In addition, increasing the static soaking time and prolonging the dynamic extraction time also help to increase the yield and the total polyphenol content, but the effects of these two methods on the increase of the red pigment content are not obvious.

[0143] The comparison of productive rate, red pigment content and total polyphenol content under each condition of table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com