An intelligent responsive graphene-based separation membrane for the separation of mixed molecules and its preparation method

A graphene-based molecular separation technology, applied in semipermeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problem of selective separation of mixed ions/molecules, and achieve easy large-scale preparation, easy control of thickness, The effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

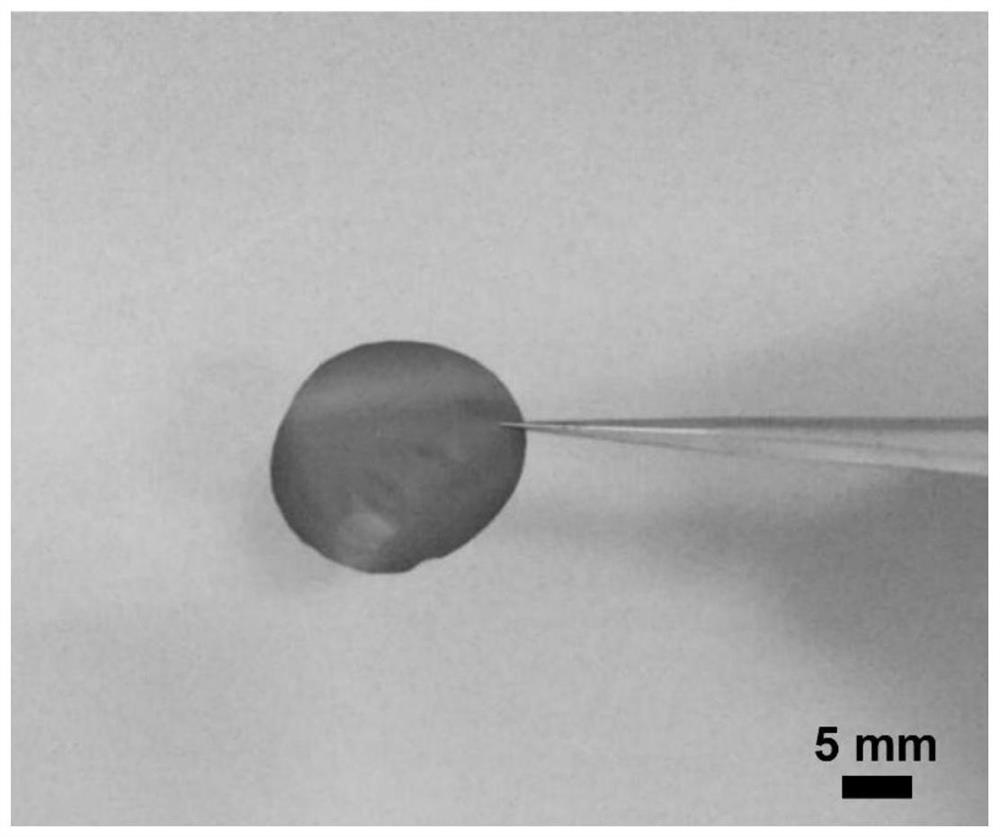

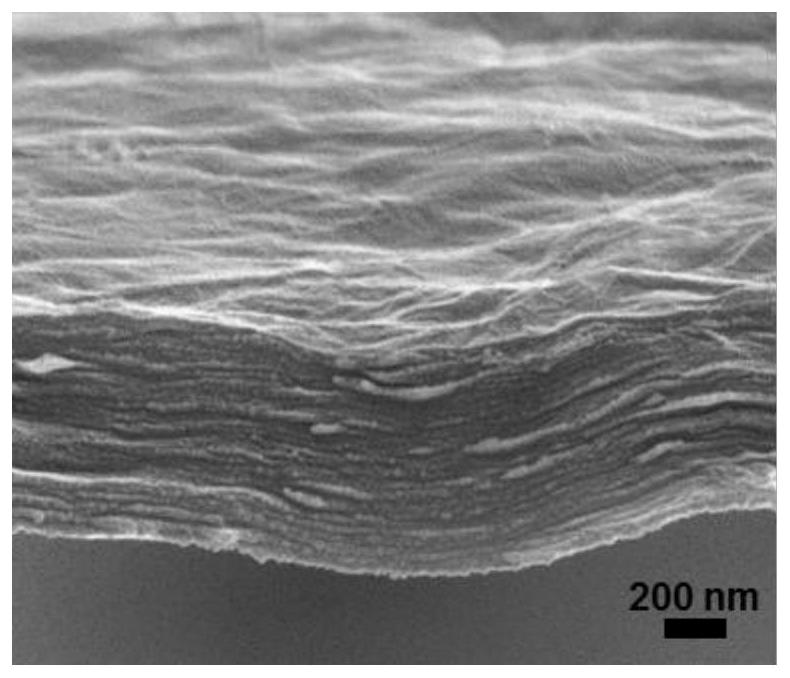

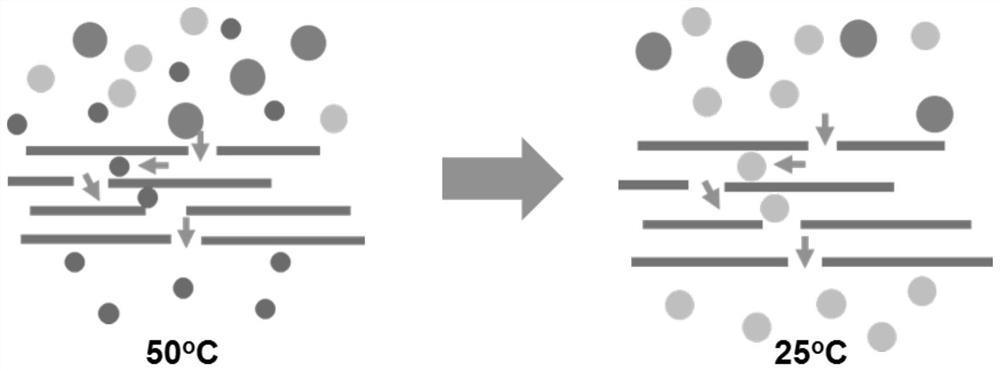

[0025] Disperse 50 mg of graphene oxide GO into 50 mL of N,N-dimethylformamide, and sonicate to obtain a GO dispersion with a concentration of 1 mg / mL.

[0026] According to the mass ratio of 100:1, 5.659g of N-isopropylacrylamide and 0.056g of azobisisobutyronitrile were added to the GO dispersion and stirred thoroughly to obtain a mixed solution. The mixed solution was transferred to a Schlenk bottle, and the moisture and oxygen in the system were removed. Then put the Schlek bottle in an oil bath heated to 65°C and stir for 12 hours. After the reaction, wash three times with 300 mL of deionized water and 300 mL of ethanol, and centrifuge at a centrifugal speed of 10,000 rpm for 1 hour to remove unreacted N-isopropylacrylamide monomer and ungrafted GO in the reaction system. poly(N-isopropylacrylamide). Finally, the obtained precipitate was freeze-dried for 48 hours under a vacuum of 0.03 mbar to obtain GO / poly(N-isopropylacrylamide) nanocomposites. 20 mg of GO / poly(N-iso...

Embodiment 2

[0028] Disperse 100 mg of rGO into 20 mL of dimethyl sulfoxide and sonicate to obtain a rGO dispersion with a concentration of 5 mg / mL. According to the mass ratio of 100:0.5, 7.206 g of acrylic acid and 0.036 g of azobisisoheptanonitrile were added to the rGO dispersion liquid and stirred thoroughly to obtain a mixed liquid. The mixed solution was transferred to a Schlenk bottle, and the moisture and oxygen in the system were removed. Then put the Schlek bottle in an oil bath heated to 55°C and stir for 6 hours. After the reaction, wash three times with 300 mL deionized water and 300 mL ethanol, and centrifuge at a centrifugal speed of 10,000 rpm for 1 hour to remove unreacted acrylic acid monomer and polyacrylic acid not grafted to rGO in the reaction system. Finally, the obtained precipitate was freeze-dried under a vacuum of 0.03 mbar for 48 hours to obtain rGO / polyacrylic acid nanocomposites. Take 100 mg of rGO / polyacrylic acid nanocomposite and disperse it in 50 mL of ...

Embodiment 3

[0030]Disperse 10 mg of graphene into 100 mL of N-methylpyrrolidone, and perform ultrasonic treatment to obtain a graphene dispersion with a concentration of 0.1 mg / mL. According to the mass ratio of 100:1.5, 8.365g of N-isopropylacrylamide-co-acrylic acid and 0.125g of dimethyl azobisisobutyrate were added to the graphene dispersion and fully stirred to obtain a mixed solution. The mixed solution was transferred to a Schlenk bottle, and the moisture and oxygen in the system were removed. Then the reaction bottle was placed in an oil bath heated to 70°C and stirred for 24 hours. After the reaction, wash three times with 300mL deionized water and 300mL ethanol and centrifuge at a centrifugal speed of 10,000 rpm for 1 hour to remove unreacted N-isopropylacrylamide-co-acrylic acid monomer and unreacted N-isopropylacrylamide-co-acrylic acid monomer in the reaction system Poly(N-isopropylacrylamide-co-acrylic acid) grafted onto graphene. Finally, the obtained precipitate was free...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com