Technology for recycling valuable metal from electric core of waste tertiary power battery

A battery cell and valuable metal technology, which is applied in the field of recycling valuable metals in waste ternary power battery cells, can solve problems such as large consumption, secondary pollution of energy, and inability to process and recycle electrolyte, and achieve stable operation, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

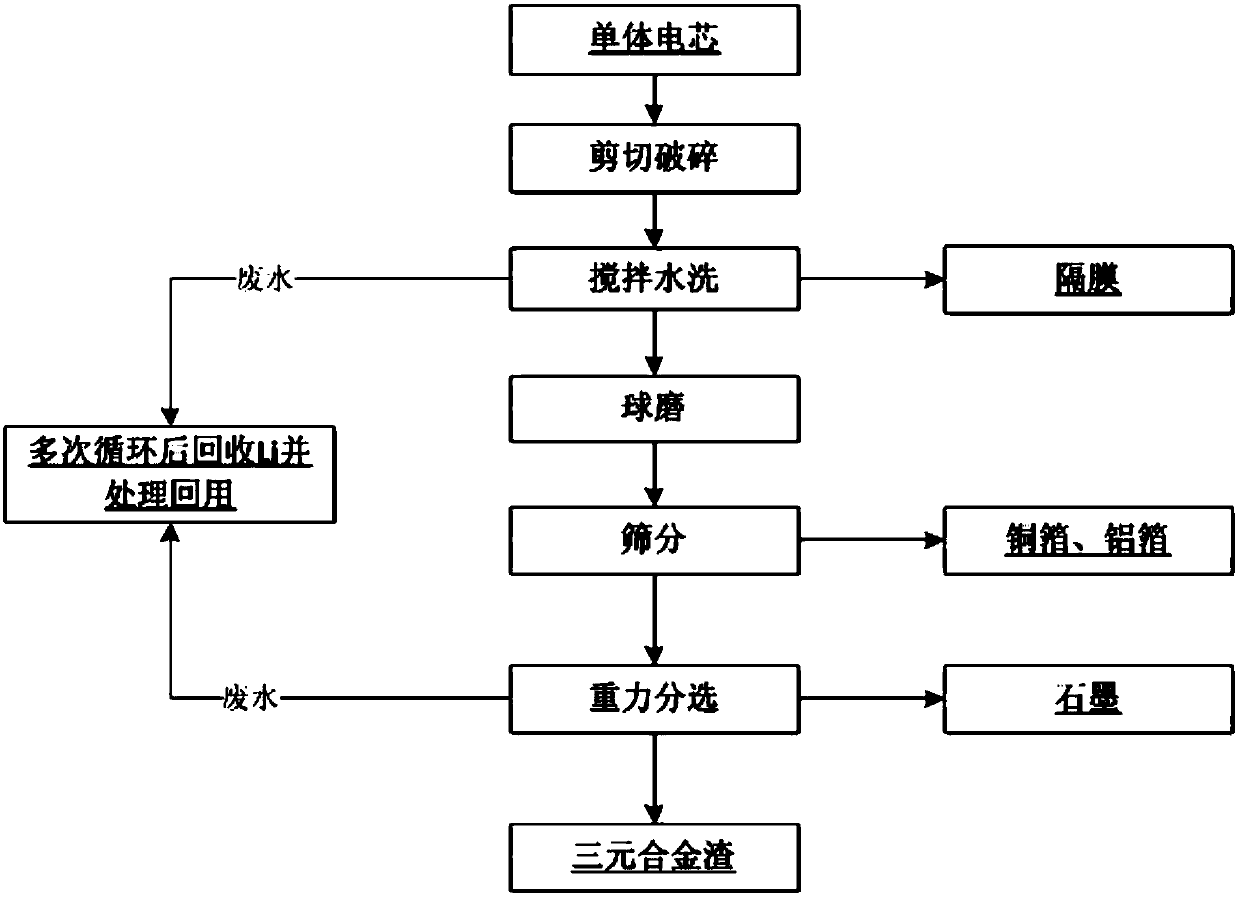

Embodiment 1

[0022] A company in Jiangsu used the fire method to recycle lithium-ion batteries for mobile phones. The process was manual disassembly-mechanical crushing-oxidation roasting-acid leaching-extraction. The diffusion of organic gas in the electrolyte in the crushing workshop is harmful to human health; the roasting workshop consumes a lot of energy, and a small amount of fly ash escapes, causing secondary pollution. Now adopt the process of the present invention to process the power battery instead, and the flow process is as follows figure 1 As shown, the specific process is as follows:

[0023] (1) The ternary power battery pack is manually disassembled to separate plastic, steel, circuit boards, wires, single cells, etc.;

[0024] (2) Under the protection of water, use a shearing crusher to crush the single cell, the crushing particle size is 10mm, and at the same time, let the electrolyte enter the water;

[0025] (3) Send the cell fragments into the washing tank for water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com