A paraffin section method for gradient dehydration of plant material

A gradient dehydration and paraffin section technology, applied in the field of botany, can solve the problems of affecting the effect of immunolocalization experiments, reducing alcohol concentration, environmental pollution, etc., to improve the quality of slices and experimental efficiency, short transparent processing time, and easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

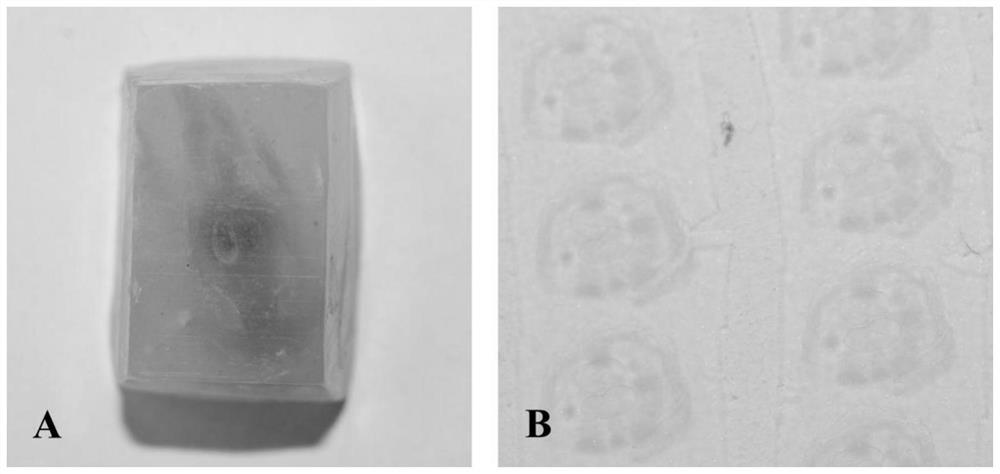

[0038] Collect fresh materials and immerse in Carnot's reagent, vacuum pump for 15-20 minutes, and then fix in Carnot's reagent for 24-36 hours; pass the fixed materials through mass fractions of 30%, 50%, 70%, 85%, 90% %, 100%, and 100% gradient ethanol solutions for dehydration, and each gradient ethanol solution was dehydrated for 0.2-2 hours; the dehydrated material was first mixed with 1 / 2 absolute ethanol, 1 / 2 xylene and 0.05wt% ~0.1wt% safranin mixed solution for 10~30 minutes, and then in pure xylene solution for 10 minutes each time; after clearing, immerse the material in 1 / 2 xylene and 1 / 2 paraffin mixed solution After 30 minutes, put it into molten pure wax with a melting point of 52-56 °C for 1-2 hours, then put the wax-soaked material into a thermostat at 58 °C to keep warm, then fill the wax box with molten paraffin, and use Pick the material with tweezers and move it into the paraffin wax in the box, place it well, and blow air on the wax surface to make the wa...

Embodiment 2

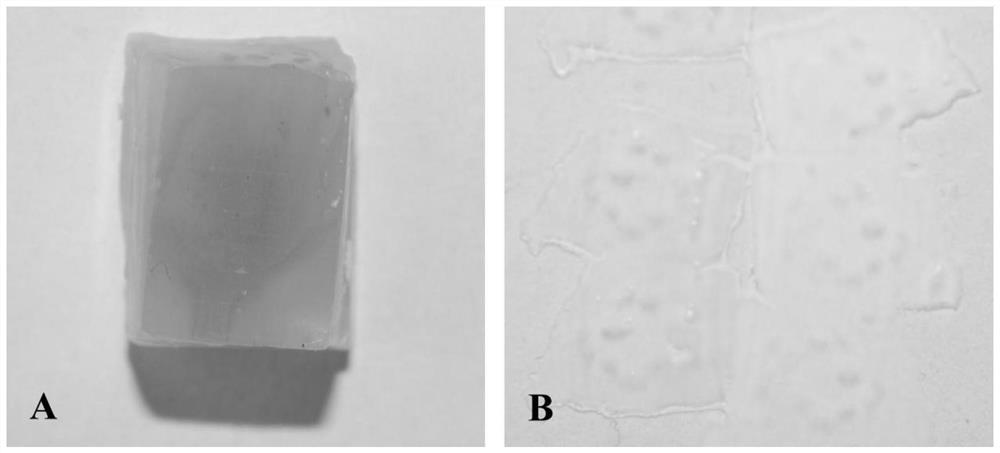

[0041] Collect fresh materials and immerse in Carnot’s reagent, vacuum pump for 15-20 minutes, and then fix in Carnot’s reagent for 24-36 hours; pass the fixed materials through mass fractions of 30%, 50%, 70% ethanol and 0.05wt% ~0.1wt% safranin, 85%, 90%, 100%, 100% gradient ethanol solution for dehydration, dehydration in each gradient ethanol solution for 0.2~2h; Transparent treatment in the mixed solution of water ethanol and 1 / 2 xylene for 10-30 minutes, then transparent treatment in pure xylene solution twice, each treatment for 10 minutes; after transparent, immerse the material in 1 / 2 xylene and 1 / 2 paraffin to mix Put it in the liquid for 30 minutes, then put it into molten pure wax with a melting point of 52-56°C for 1-2 hours, put the wax-soaked material in a constant temperature box at 58°C to keep warm, and then fill the wax box with molten paraffin. Use tweezers to pick up the material and move it into the paraffin in the box, place it well, and blow air on the ...

Embodiment 3

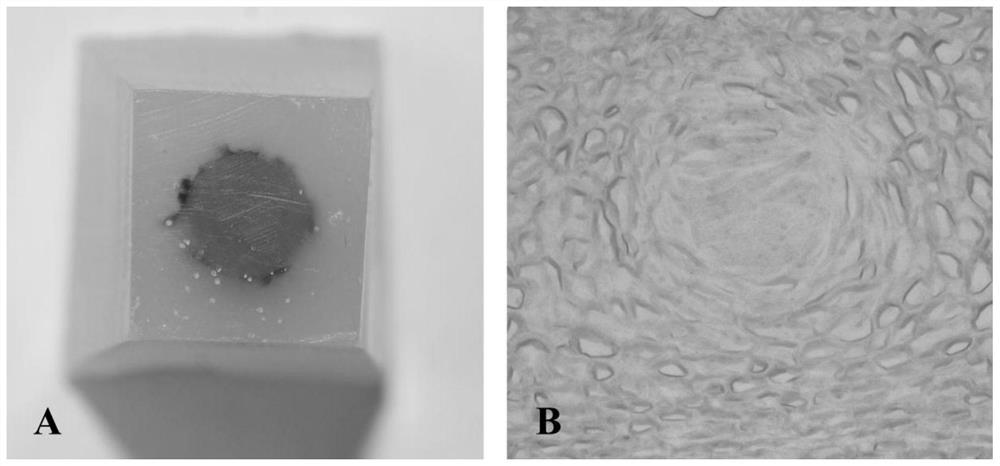

[0044] Collect fresh materials and immerse in Carnot's reagent, vacuum pump for 15-20 minutes, and then fix in Carnot's reagent for 24-36 hours; pass the fixed materials through mass fractions of 30%, 50%, 70%, 85%, 90% %, 100%, 100% gradient ethanol solution for dehydration, dehydration in each gradient ethanol solution for 0.2~2h; the dehydrated material is first transparent in the mixed solution of 1 / 2 absolute ethanol and 1 / 2 xylene Treat for 10-30 minutes, then transparently treat twice in pure xylene solution, each time for 10 minutes; after transparent, immerse the material in 1 / 2 xylene and 1 / 2 paraffin mixture for 30 minutes, and then put it into After soaking in molten pure wax at ℃ for 1-2 hours, put the wax-soaked material in a constant temperature box at 58℃ to keep warm, then fill the wax box with molten paraffin, pick the material with tweezers and move it into the paraffin wax in the box, and place it Put it well, and blow air on the wax surface to make the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com