Poly (METH) acrylic acid (SALT) granular water absorbent and method for producing same

A manufacturing method, polyacrylic acid technology, applied in the direction of absorbent pads, bandages, medical science, etc., can solve the problems of increased return flow, difficulty in bubble dispersion and stabilization, and difficulty in stable manufacturing, etc., to achieve reduced return flow and excellent liquid absorption speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

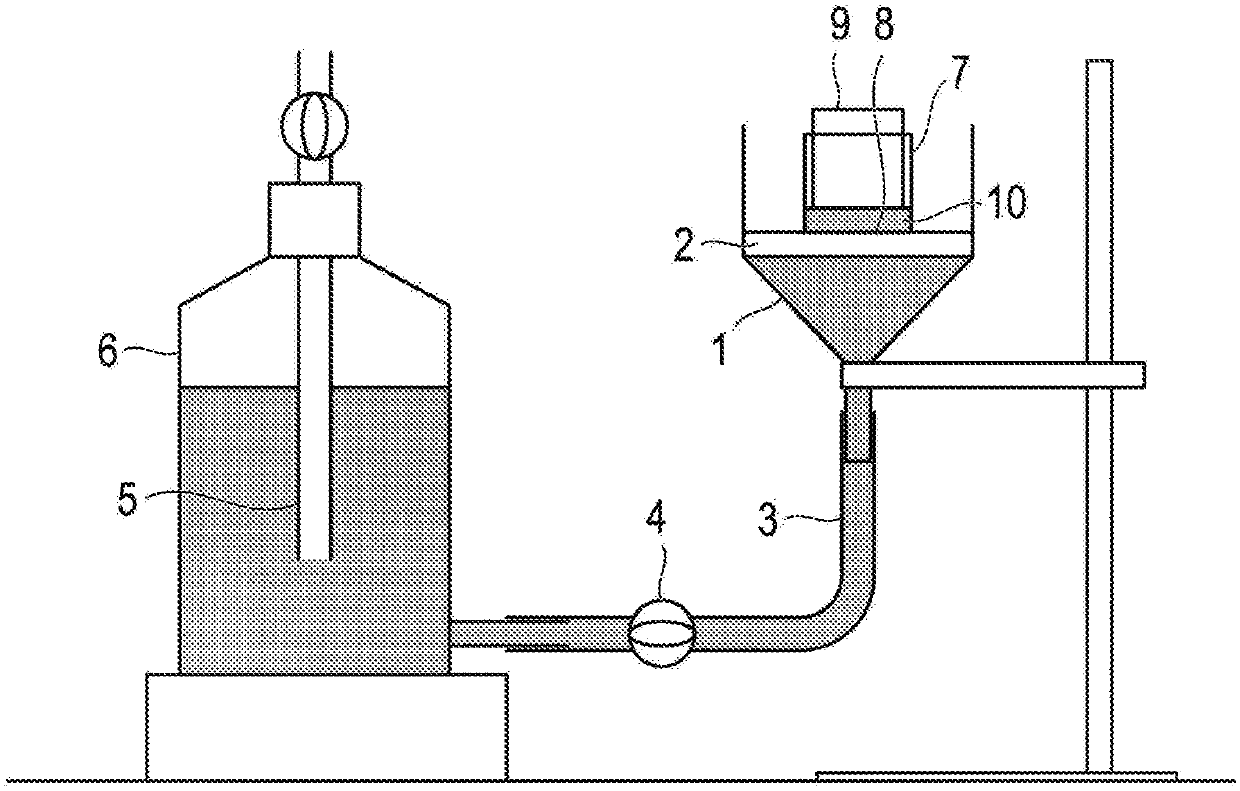

[0776] (Preparation and polymerization process of (meth)acrylic acid (salt) monomer aqueous solution)

[0777] 170 g of acrylic acid, 1800 g of a 37% by weight sodium acrylate aqueous solution, polyethylene glycol diacrylate ( Weight average molecular weight 523) 0.99g, polyethylene glycol (weight average molecular weight 2000, manufactured by Wako Pure Chemical Industries, Ltd.) 6.688g (0.8% by weight relative to the monomer component) and deionized water 216g and mixed, immersed in a 20°C in a water bath up to a height of 10 mm from the bottom.

[0778] Nitrogen gas was introduced into this aqueous solution to degas it for 20 minutes. After confirming that the solution had reached 20° C., 6.61 g of a 20% by weight sodium persulfate aqueous solution and 6.33 g of a 0.1% by weight L-ascorbic acid aqueous solution were added under a nitrogen flow atmosphere, followed by stirring and mixing. The monomer concentration was 38% by weight. The polymerization started after 1 minut...

Embodiment 2

[0792] Except that the amount of polyethylene glycol used was changed to 3.344 g (0.4% by weight relative to the monomer component), the same operation as in Example 1 was carried out to obtain a water-absorbent resin powder (B2). Treated water-absorbent resin particles (S2), particulate water-absorbing agent (EX-2).

Embodiment 3

[0794] Except that the amount of polyethylene glycol used was changed to 10.03 g (1.2% by weight relative to the monomer component), the same operation as in Example 1 was carried out to obtain a water-absorbent resin powder (B3). Treated water-absorbent resin particles (S3), particulate water-absorbing agent (EX-3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com