Nano cobalt phosphide-porous carbon nanofiber flexible membrane and preparation method thereof

A nanofiber membrane and nanofiber technology, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as single structure and small specific surface area, and achieve simple preparation process and large specific area. Effect of surface area, mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, concrete steps are:

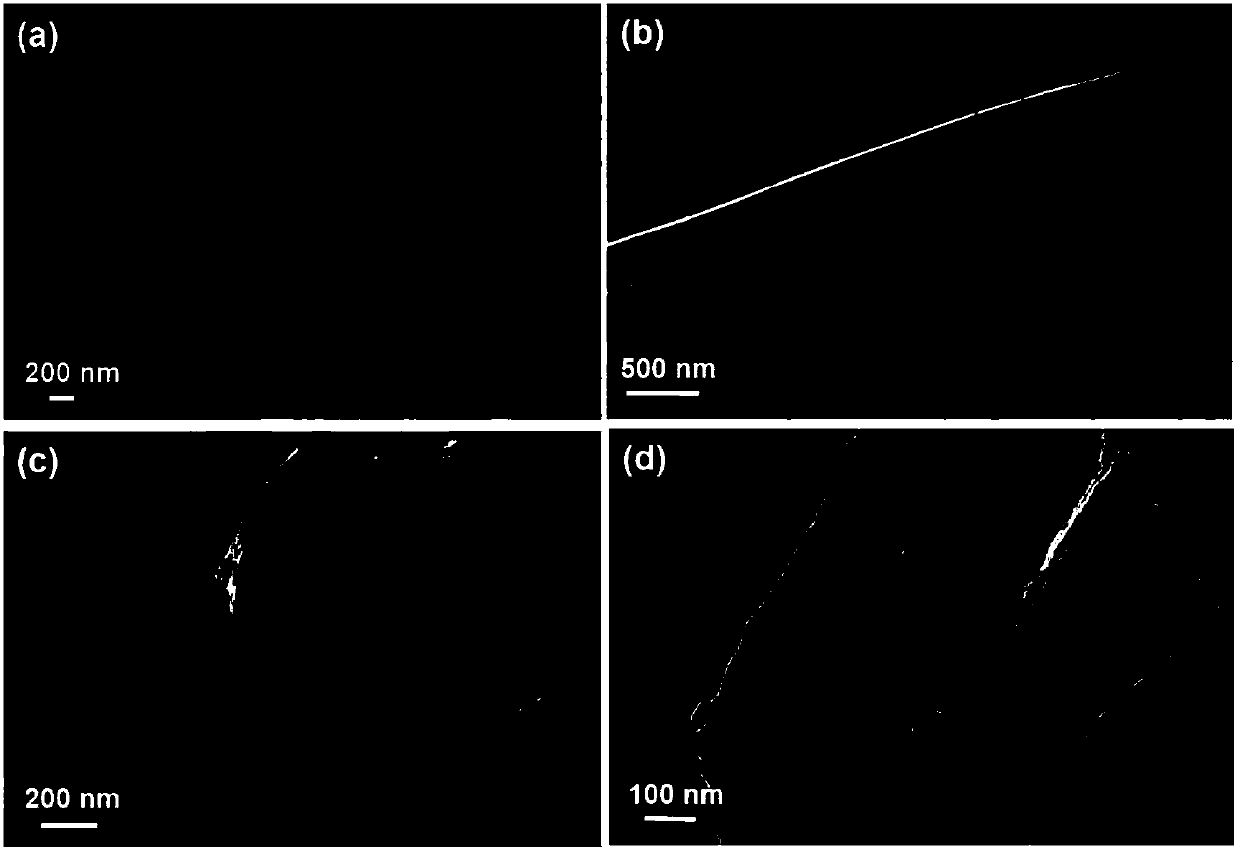

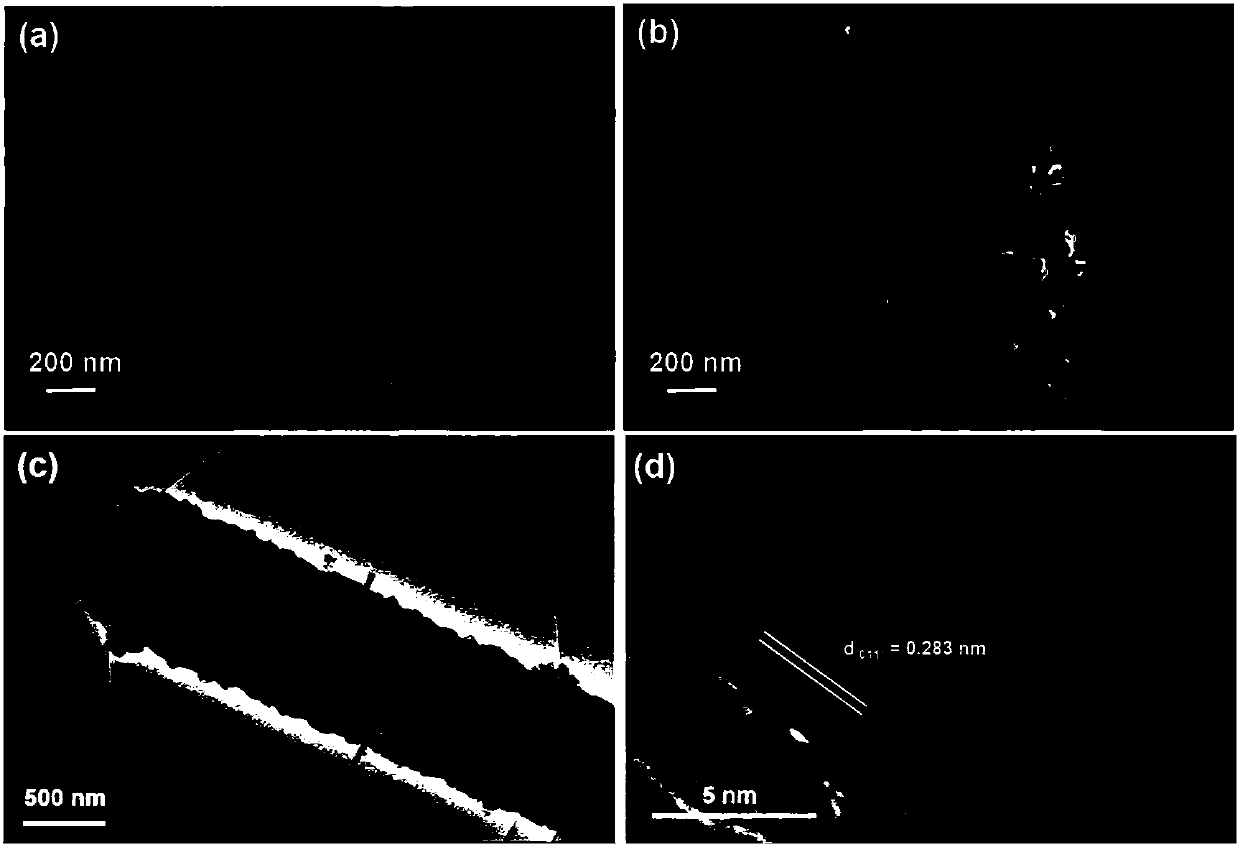

[0038] (1) First, the porous carbon nanofiber membrane was prepared by electrospinning, and the specific steps were as follows:

[0039] Add 0.6g polystyrene (PS) and 1g polyacrylonitrile (PAN) together to 10mL N,N - In dimethylformamide, the precursor spinning solution was prepared by stirring in a water bath at 80°C.

[0040] The prepared spinning solution was injected into a 5 mL syringe with a needle diameter of 0.5 mm for electrospinning. The specific spinning parameters were: voltage 20 kV, injection speed 1.5 mL h -1 , the receiving distance is 15 cm.

[0041] The prepared polyacrylonitrile / polystyrene fiber membrane was pre-oxidized in an air atmosphere at 250 °C, and the pre-oxidation time was 2 h.

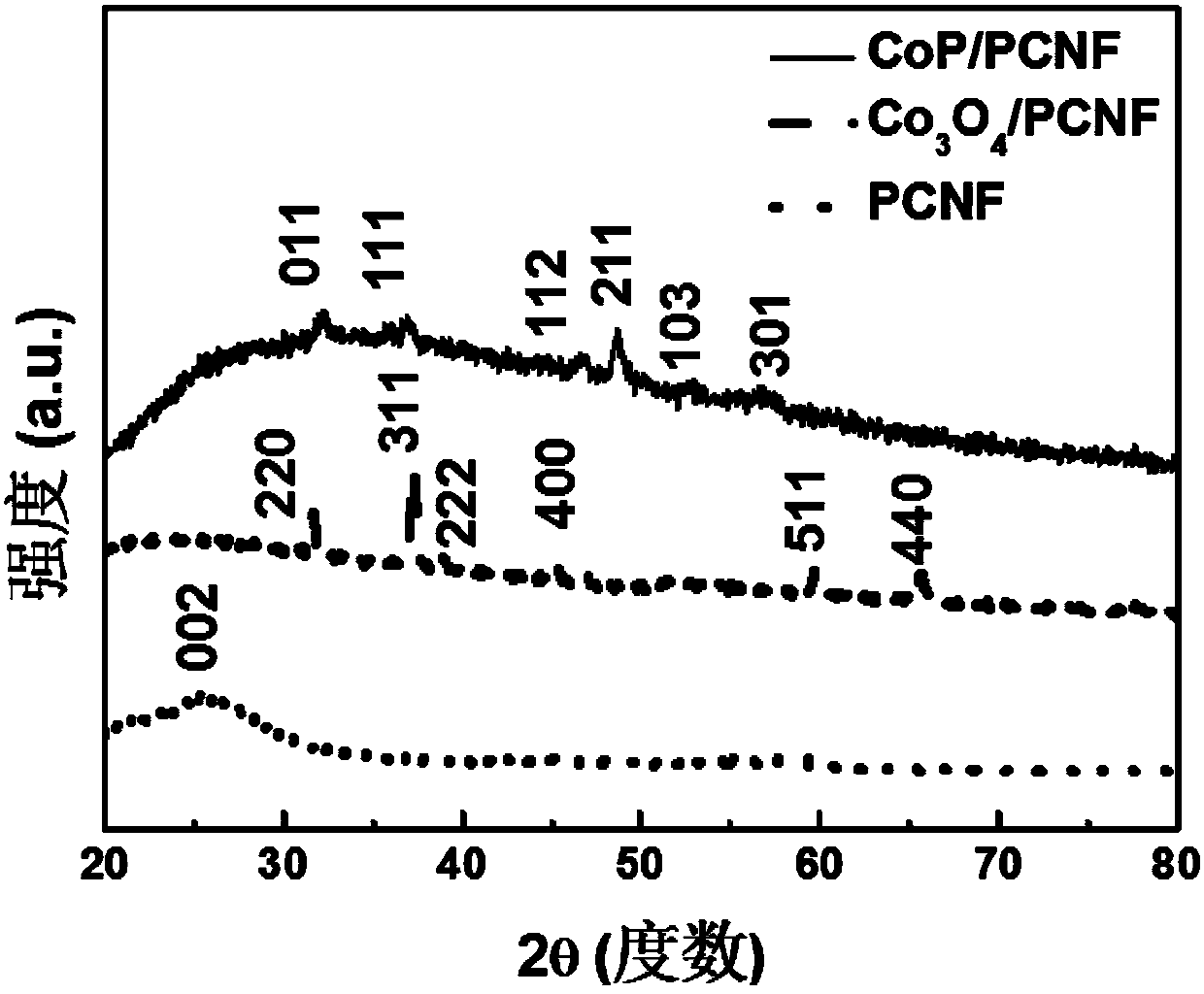

[0042] The pre-oxidized polyacrylonitrile / polystyrene fiber membrane was heated at 5 °C for min in an argon atmosphere. -1 The heating rate is to rise to 800°C for carbonization, and the carbonization time is 2 h. The obtain...

Embodiment 2

[0050] The amount of cobalt acetate in Example 1 was changed to 0.4 mmol, and the rest were the same as in Example 1, and the hybrid material finally obtained was recorded as CoP / PCNF-0.4. The component material at 0.5 M H 2 SO 4 An overpotential of 83mV is required to achieve 10 mA cm in -2 the current density.

Embodiment 3

[0052] The amount of cobalt acetate in Example 1 was changed to 0.6 mmol, and the rest were the same as in Example 1, and the hybrid material finally obtained was recorded as CoP / PCNF-0.6. The component material at 0.5 M H 2 SO 4 An overpotential of 97mV is required to reach 10 mA cm in -2 the current density.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com