Method for alleviating swelling of filamentous bacterium-containing activated sludge under low-temperature condition

A technology of activated sludge and low-temperature conditions, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., and can solve unstable operation effects, reduced mud-water separation effect, long recovery period, etc. problems, to achieve the effect of enhancing the separation effect of mud and water, increasing the specific gravity of sludge, and increasing the sludge load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

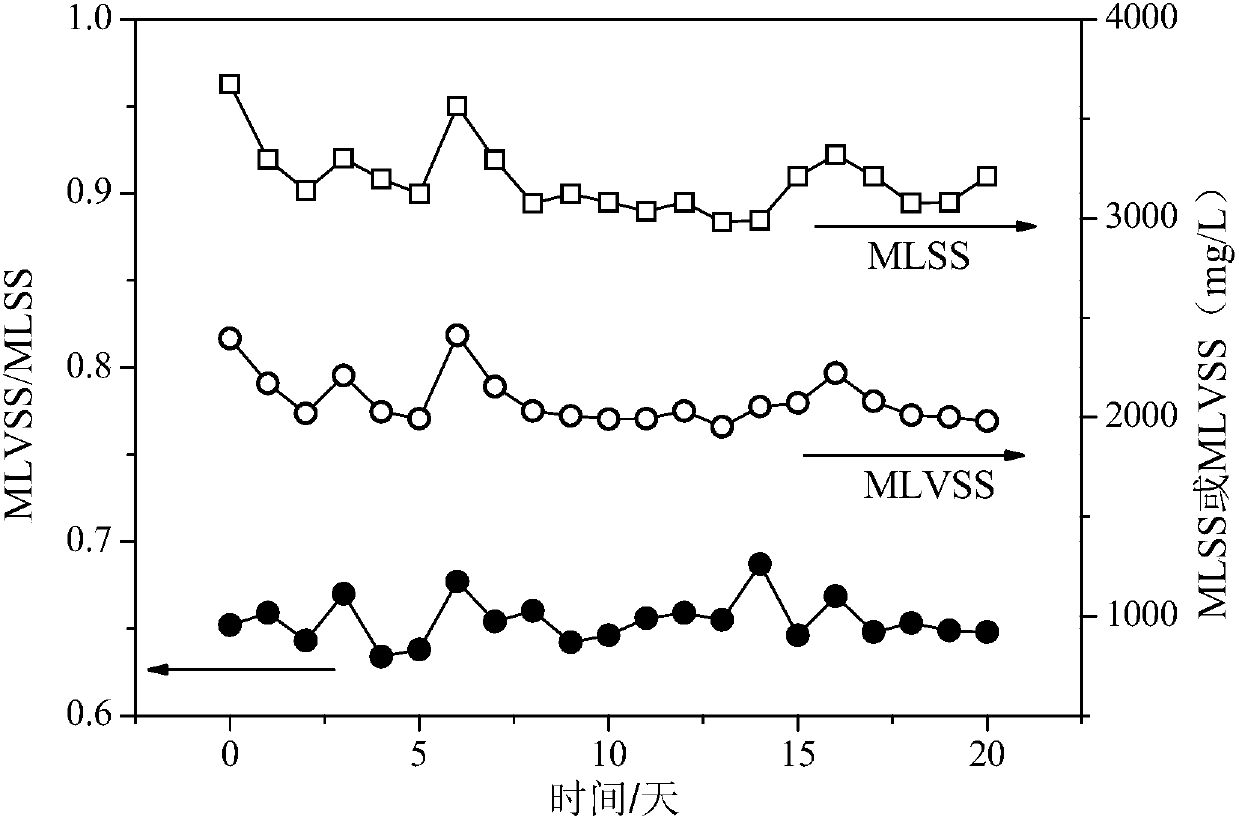

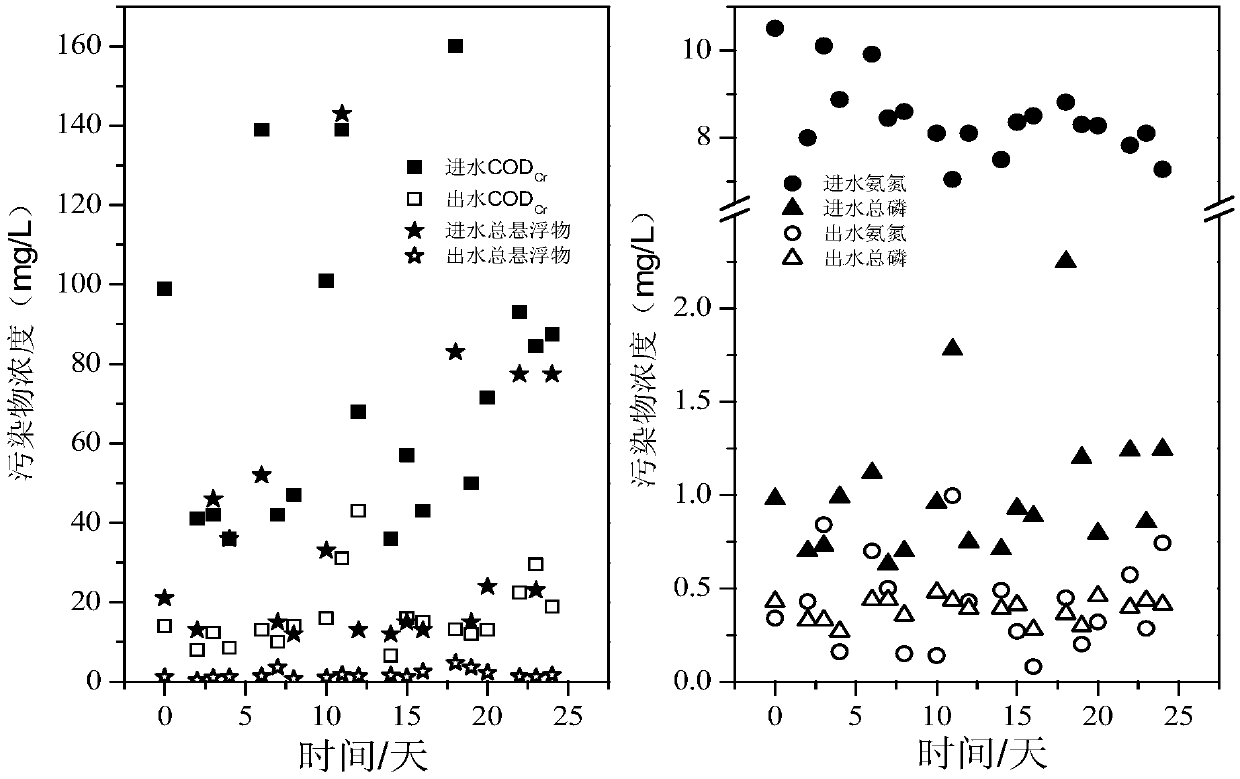

[0030] Step 1: Increase the sludge load. According to the sludge concentration (3200 mg / L) of the expanded sludge and the influent COD (80-100 mg / L) index, the sludge load is increased by increasing the sludge discharge, so that the sludge load is from 0.025kgCOD / kgMLSS• d reaches 0.075kgCOD / kgMLSS•d. The sewage load in the reaction tank increases, which is more suitable for the growth of microbes and inhibits the growth of filamentous bacteria with stronger growth ability under low load.

[0031] Step 2: The external boiler steam is used to heat the inlet water in the regulating tank, and the blast aeration equipment is used to increase aeration. The standby blast aeration device was turned on, and the DO concentration of the water body was increased from 3.0 mg / L to 3.5 mg / L. A higher dissolved oxygen concentration can promote nitrification and avoid local anaerobic and hypoxia in the reaction tank. Due to the heat tracing of the external boiler steam and the heat generation ...

Embodiment 2

[0035] Step 1: Increase the sludge load. According to the sludge concentration (3200 mg / L) of the expanded sludge and the influent COD (80-100 mg / L) indicators, the sludge load is reduced by increasing the sludge discharge, so that the sludge load is reduced from 0.03 kgCOD / kgMLSS· d reaches 0.09 kgCOD / kgMLSS·d.

[0036] Step 2: The external boiler steam is used to heat the inlet water in the regulating tank, and the blast aeration equipment is used to increase aeration. The standby blast aeration device was turned on, and the DO concentration of the water body was increased from 3.0 mg / L to 4 mg / L. A higher dissolved oxygen concentration can promote nitrification and avoid local anaerobic and hypoxia in the reaction tank. Due to the heat tracing of the external boiler steam and the heat generation of the blast aeration equipment, the temperature of the mud-water mixture rose from 7°C to 11°C.

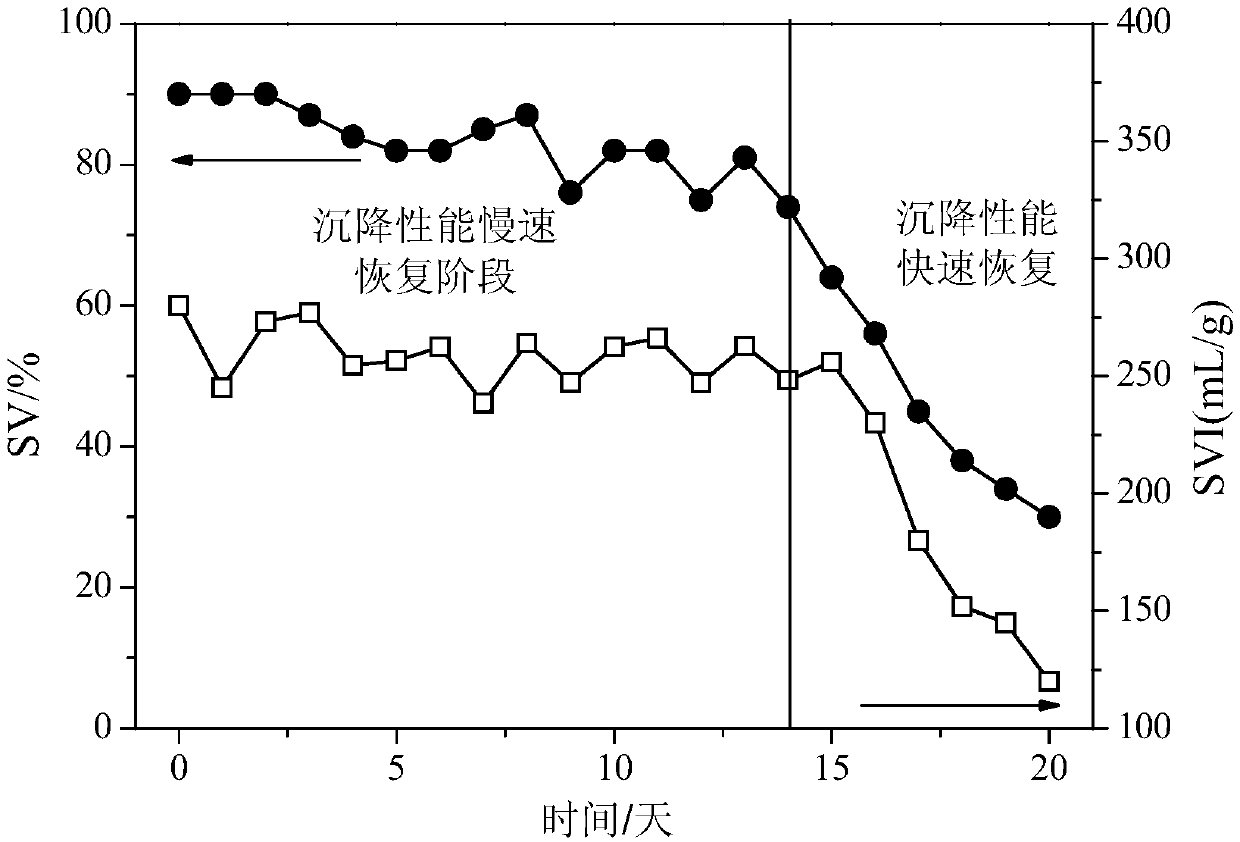

[0037] Step 3: Loess dosing is divided into two stages. In the first stage, loess is ...

Embodiment 3

[0040] Step 1: Increase the sludge load. According to the sludge concentration (3200 mg / L) of the expanded sludge and the influent COD (80-100 mg / L) indicators, the sludge load is reduced by increasing the sludge discharge, so that the sludge load is reduced from 0.03 kgCOD / kgMLSS· d reaches 0.08 kgCOD / kgMLSS·d.

[0041] Step 2: The external boiler steam is used to heat the inlet water in the regulating tank, and the blast aeration equipment is used to increase aeration. The standby blast aeration device is turned on, and the DO concentration of the water body is increased from 2.9 mg / L to 3.8 mg / L. The higher dissolved oxygen concentration can promote nitrification and avoid local anaerobic and hypoxia in the reaction tank. Due to the heating of the external boiler steam and the heat generation of the blast aeration equipment, the temperature of the mud-water mixture rose from 10°C to 12°C.

[0042] Step 3: Loess dosing is divided into two stages. In the first stage, loess is un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com