High-plant fiber content wood-plastic composite material and preparation method thereof

A wood-plastic composite material and plant fiber technology, which is applied in the field of wood-plastic composite material and its preparation, can solve the problems of affecting the comprehensive performance of the composite material, reducing the impact strength and tensile strength of the composite material, and failing to transmit the stress effectively. High-value utilization, improved dimensional stability, and improved interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

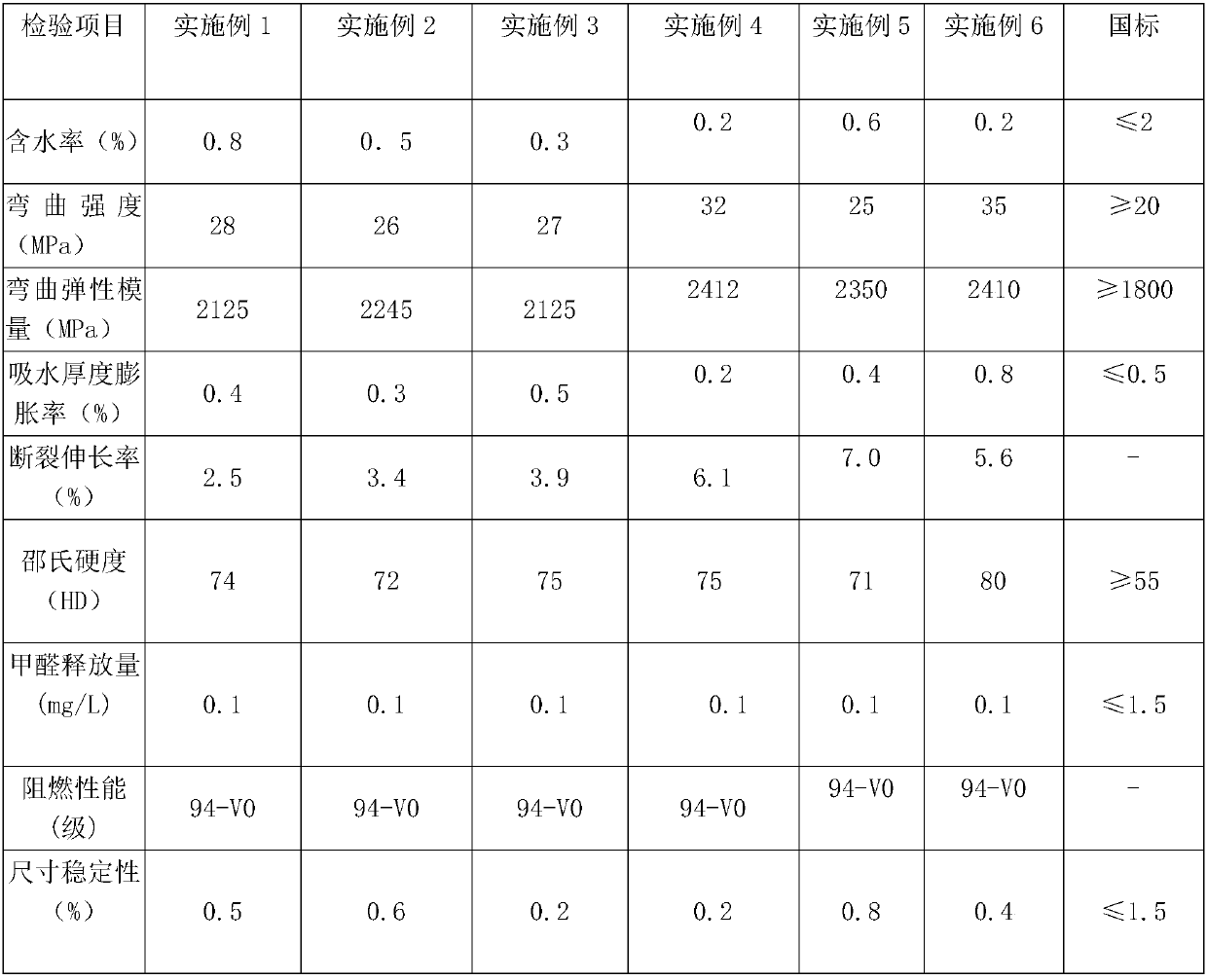

Examples

Embodiment 1

[0043] A wood-plastic composite material with high plant fiber, comprising the following raw materials in parts by weight: 53 parts of PVC resin powder; 35 parts of plant fiber powder; 0.5 part of titanate coupling agent; 2 parts of dimethyl ester; 4 parts of environmental stabilizer; 1.5 parts of dioctyl ester; 2 parts of polyethylene wax; 2 parts of acrylic polyester.

[0044] A preparation method of wood-plastic composite material with high plant fiber, comprising the steps of:

[0045] 1) Drying the plant fiber powder at a temperature of 110°C to make the water content <1%;

[0046] 2) Add the dried plant fiber powder into a high-speed mixer, stir and mix at a high speed at 120°C, the speed of the high-speed mixer is 1500 rpm, and the ratio of plant fiber powder to titanate coupling agent is 70 : 1 Add titanate coupling agent and continue stirring for 10min to obtain modified plant fiber powder;

[0047] 3) Mix the modified plant fiber powder obtained in step 2) with PVC...

Embodiment 2

[0051]A wood-plastic composite material with high plant fiber, comprising the following raw materials in parts by weight: 52 parts of PVC resin powder; 40 parts of plant fiber powder; 1 part of titanate coupling agent; 1 part of dimethyl ester; 2 parts of environmental stabilizer; 1 part of dioctyl ester; 1 part of polyethylene wax; 2 parts of acrylic polyester.

[0052] A preparation method of wood-plastic composite material with high plant fiber, comprising the steps of:

[0053] 1) Drying the plant fiber powder at a temperature of 110°C to make the water content <1%;

[0054] 2) Add the dried plant fiber powder into a high-speed mixer, stir and mix at a high speed at 120°C, the speed of the high-speed mixer is 1500 rpm, and the ratio of plant fiber powder to titanate coupling agent is 70 : 1 Add titanate coupling agent and continue stirring for 10min to obtain modified plant fiber powder;

[0055] 3) Mix the modified plant fiber powder obtained in step 2) with PVC resin p...

Embodiment 3

[0059] A wood-plastic composite material with high plant fiber, comprising the following raw materials in parts by weight: 43 parts of PVC resin powder; 45 parts of plant fiber powder; 2 parts of titanate coupling agent; 2 parts of dimethyl ester; 3 parts of environmental stabilizer; 2 parts of dioctyl ester; 1 part of polyethylene wax; 1 part of acrylic polyester.

[0060] A preparation method of wood-plastic composite material with high plant fiber, comprising the steps of:

[0061] 1) Drying the plant fiber powder at a temperature of 110°C to make the water content <1%;

[0062] 2) Add the dried plant fiber powder into a high-speed mixer, stir and mix at a high speed at 120°C, the speed of the high-speed mixer is 1500 rpm, and the ratio of plant fiber powder to titanate coupling agent is 22.5 : 1 Add titanate coupling agent and continue stirring for 10min to obtain modified plant fiber powder;

[0063] 3) Mix the modified plant fiber powder obtained in step 2) with PVC re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com