Water-based heat-insulation coating and preparation method thereof

A thermal insulation and coating technology, applied in the coating and other directions, can solve the problems of harm to the human body and the environment, high toxicity of organic substances, etc., and achieve the effects of not easy to fall off, excellent coating performance, and excellent thermal insulation function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

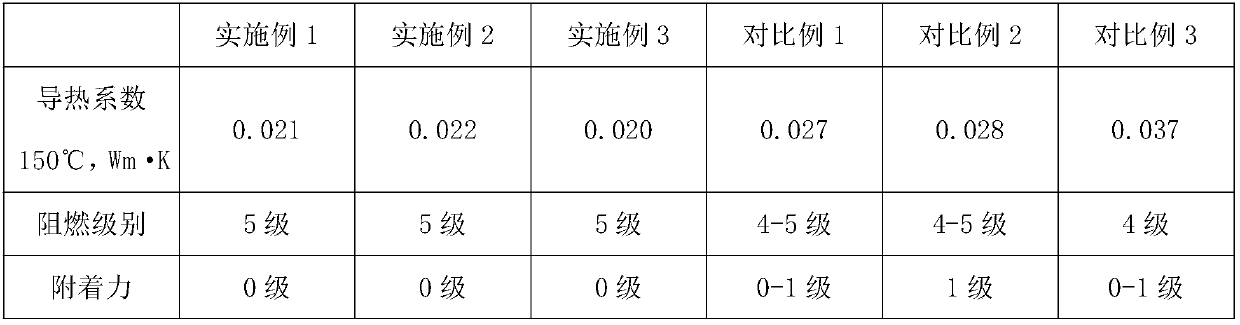

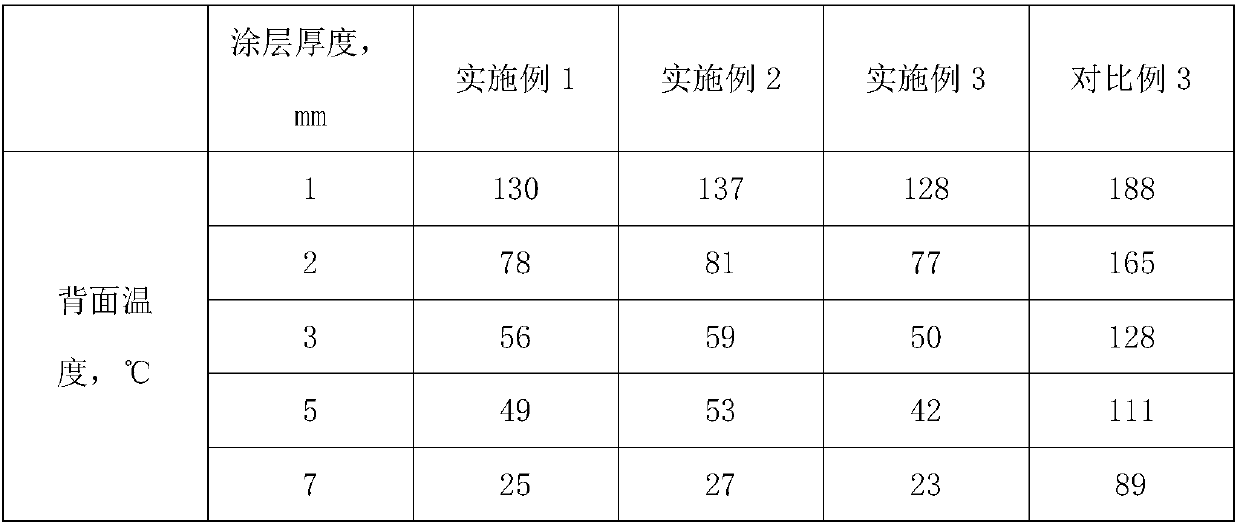

Examples

Embodiment 1

[0022] A water-based thermal insulation coating, comprising the following raw materials in parts by weight: 18 parts of water glass, 20 parts of sodium metaaluminate, 35 parts of silica sol, 8 parts of aluminum sulfate, 2 parts of sodium hydroxide, 15 parts of calcium sulfate, bentonite 8 parts, 3 parts cinnabar, 80 parts water. Its preparation method comprises the following steps:

[0023] (1) Preparation of crystal nuclei: Weigh each component in proportion for later use, add sodium metaaluminate into water glass, stir at 35°C for 8 hours at a stirring speed of 200r / min, and obtain mixed solution A;

[0024] (2) Preparation of gel: first place aluminum sulfate in a reaction vessel, then slowly add silica sol, control the feeding time at 40 minutes, stir for 30 minutes, and stir at a speed of 600 r / min, then dissolve sodium hydroxide in a part of water, add Put it into the reaction vessel, continue to stir for 60 minutes, and finally add the mixed solution A into the reactio...

Embodiment 2

[0027] A water-based thermal insulation coating, comprising the following raw materials in parts by weight: 25 parts of water glass, 12 parts of sodium metaaluminate, 55 parts of silica sol, 5 parts of aluminum sulfate, 4 parts of sodium hydroxide, 10 parts of calcium sulfate, bentonite 12 parts, 1 part red clay, 130 parts water. Its preparation method comprises the following steps:

[0028] (1) Preparation of crystal nuclei: Weigh each component in proportion for later use, add sodium metaaluminate into water glass, stir at 25°C for 16 hours at a stirring speed of 100r / min, and obtain mixed solution A;

[0029] (2) Preparation of the gel: first place aluminum sulfate in the reaction vessel, then slowly add the silica sol, the addition time is controlled at 20 minutes, stir for 90 minutes, and the stirring speed is 400 r / min. Then dissolve sodium hydroxide in a part of water, add it into the reaction vessel, continue to stir for 40 minutes, and finally add the mixed liquid A ...

Embodiment 3

[0032] A water-based thermal insulation coating, comprising the following raw materials in parts by weight: 22 parts of water glass, 16 parts of sodium metaaluminate, 45 parts of silica sol, 7 parts of aluminum sulfate, 3 parts of sodium hydroxide, 12 parts of calcium sulfate, bentonite 10 parts, 2 parts of titanium dioxide, 100 parts of water. Its preparation method comprises the following steps:

[0033] (1) Preparation of crystal nuclei: Weigh each component in proportion for later use, add sodium metaaluminate into water glass, stir at 33°C for 12 hours at a stirring speed of 150r / min, and obtain mixed solution A;

[0034] (2) Preparation of gel: first place aluminum sulfate in a reaction vessel, then slowly add silica sol, control the feeding time at 30 minutes, stir for 60 minutes, and stir at a speed of 500 r / min, then dissolve sodium hydroxide in a part of water, add Into the reaction vessel, continue to stir for 50min. Finally, add the mixed solution A into the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com