Multi-stage cutting drainage air distribution device, drying chamber and dryer

A technology of air distribution device and drying room, which is applied in the field of direct-fired chain plate hot air tunnel drying room and dryer, and can solve the problems of difficulty in changing and adjusting fan operating parameters, complex and targeted design and calculation, and reduction Reliance on small air volume and wind pressure to achieve the effect of improving fuel utilization rate and temperature control response ability, compact structure, and low running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

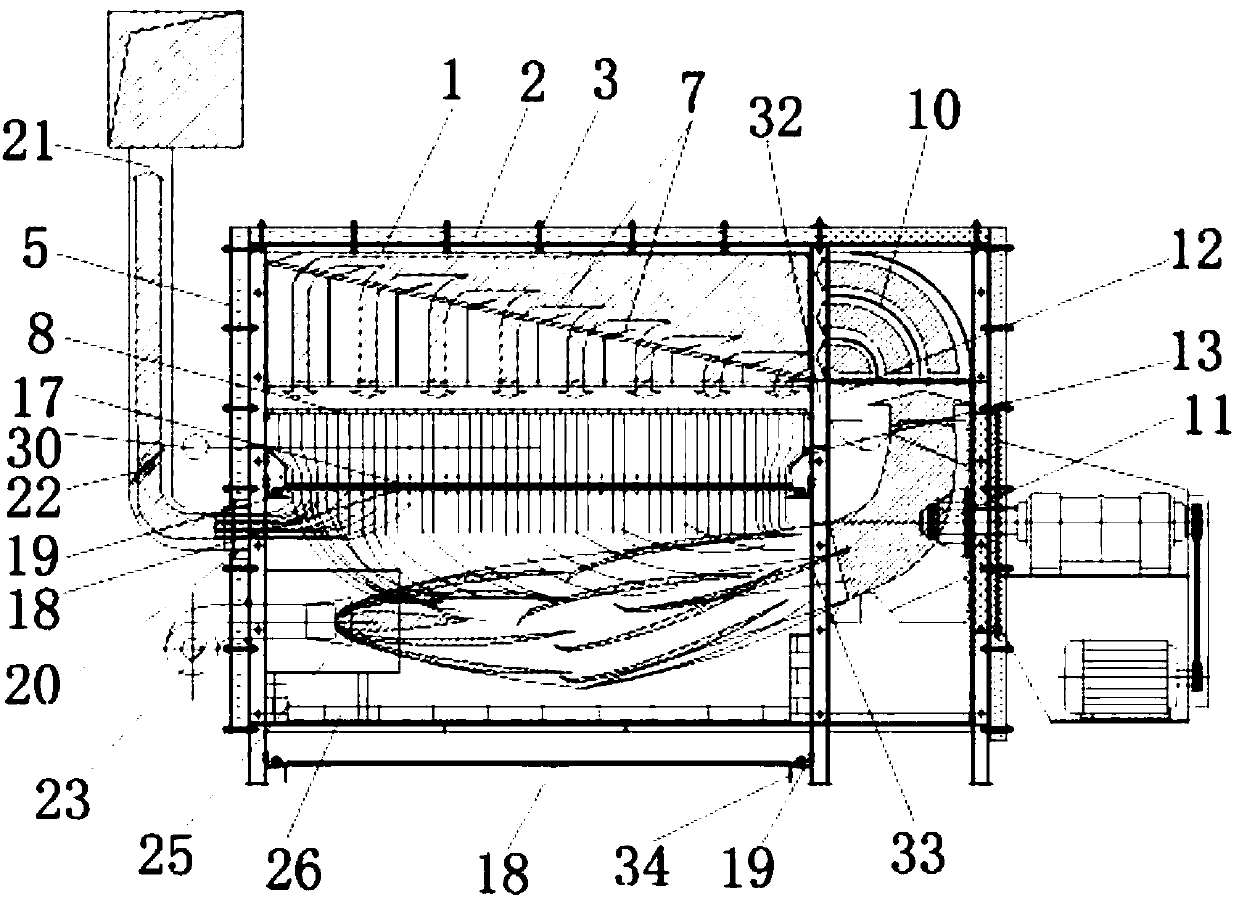

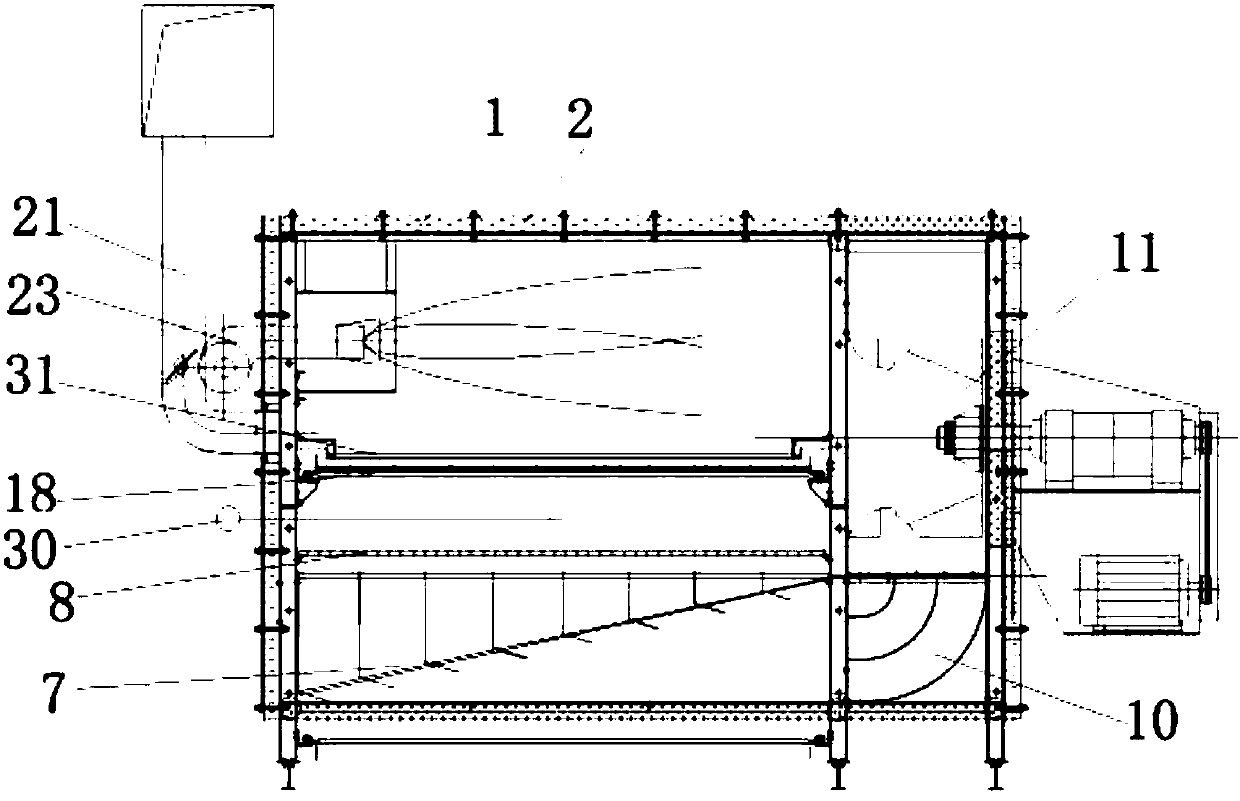

[0039] figure 1 It is a structural schematic diagram of the down blowing hot air drying chamber of the present invention. From figure 2 and figure 1 It can be clearly seen that the difference between the down blowing hot air drying room and the up blowing hot air drying room is that the starting units in the left area and the right area are different from bottom to top, but the order of each unit is is consistent. Let's take the hot air drying room as an example to illustrate.

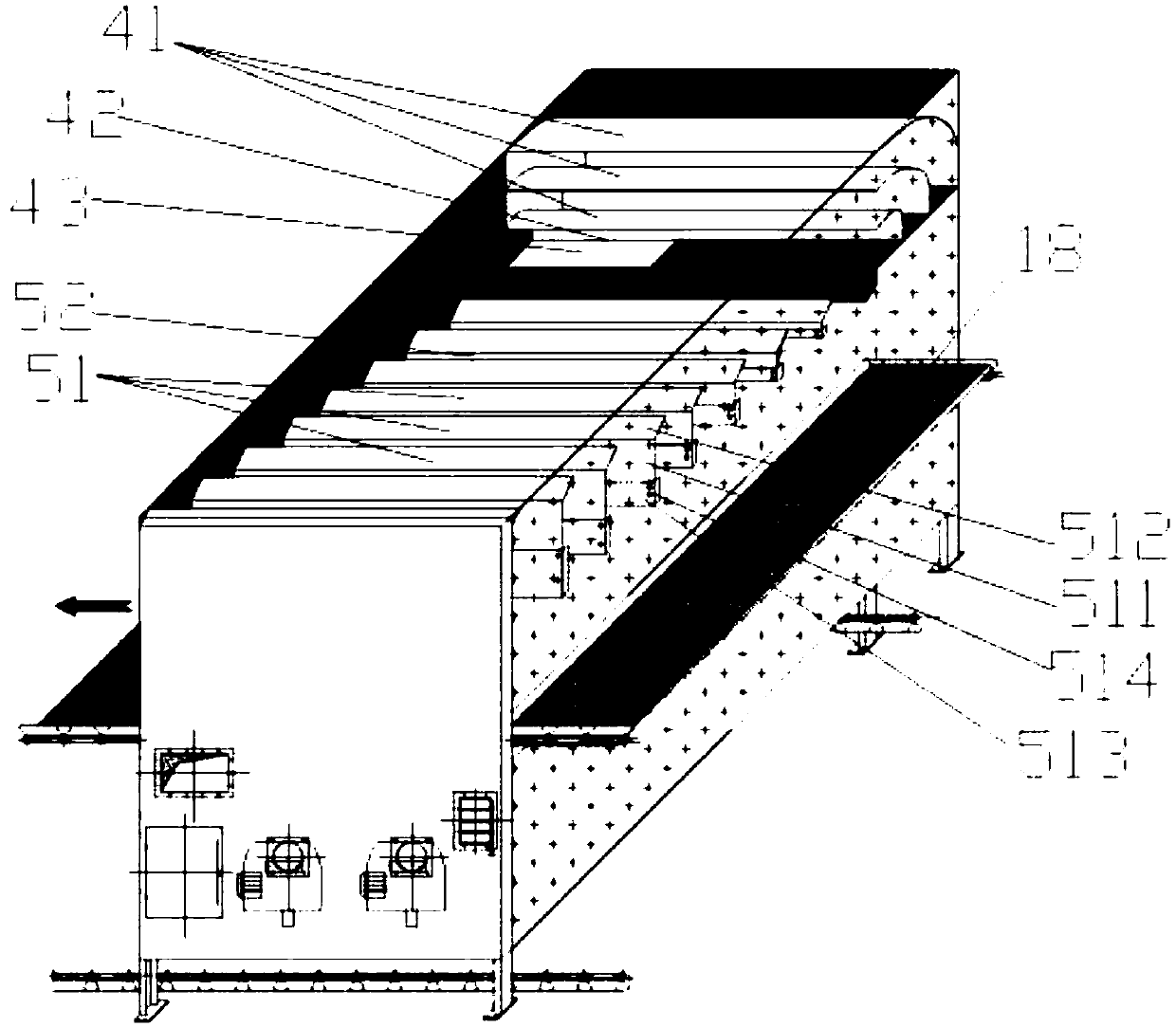

[0040] The down-blowing hot air drying chamber roughly includes five functional units: a direct-fired heating unit (referred to as a combustion chamber), a hot air mixing booster unit, a multi-stage uniform air unit, a through-flow drying unit, a negative pressure dehumidification unit and an automatic control unit. . Among them, the direct-fired heating unit, the hot air mixing booster unit, the multi-stage uniform air unit, and the through-flow drying unit are arranged inside the drying chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com