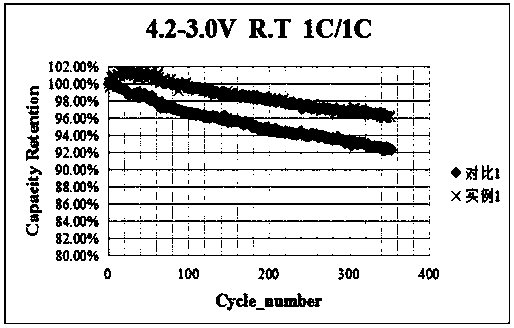

Preparation method of nickel-cobalt lithium manganate anode material through hydro-thermal synthesis

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of affecting the service life of lithium batteries, residual alkaline compounds, and partial mixing of lithium source waste, so as to avoid waste Effects of local uneven mixing, reduction of basic compounds, and shortening of sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] S1, make nickel sulfate 11.62Kg, cobalt sulfate 4.48Kg, manganese sulfate 2.38Kg according to Ni:Mn:Co molar ratio 6:2:2 to prepare 2mol / L sulfate solution, take aluminum nitrate 0.063Kg to dissolve and add the above-mentioned salt Mixed salt solution A is formed in the solution; the concentration of sodium hydroxide and ammonia water is respectively prepared as mixed alkali solution B of 3.0mol / L and 0.45mol / L;

[0028] S2, the prepared mixed salt solution A and the mixed alkali solution B are pumped into the reactor at the same time, the flow of the alkali solution B is controlled so that the pH of the mixed reaction solution in the reactor is 10.8±0.2, and the stirring speed of the mixed solution in the reactor is 200 rpm, the reaction temperature is 65°C, after the co-precipitation reaction is completed, the obtained precipitate is washed, filtered and dried to obtain a doped nickel-cobalt-manganese ternary precursor;

[0029] S3, uniformly mix the nickel-cobalt-man...

Embodiment 2

[0032] S1, 11.62Kg of nickel sulfate, 4.48Kg of cobalt sulfate, and 2.38Kg of manganese sulfate are prepared into a 2mol / L sulfate solution according to the molar ratio of Ni:Mn:Co 6:2:2. After dissolving 0.063Kg of aluminum nitrate, add the above Mixed salt solution A is formed in the salt solution; the concentration of preparing sodium hydroxide and ammonia water is respectively 3.0mol / L and 0.45mol / L mixed alkali solution B;

[0033] S2, the prepared mixed salt solution A and mixed alkali solution B are pumped into the reaction kettle at the same time, the flow of alkali solution B is controlled so that the pH of the mixed reaction solution in the reaction kettle is 11.2±0.2, and the stirring speed of the mixed solution in the reaction kettle is 400 rpm, the reaction temperature is 50°C, after the co-precipitation reaction is completed, the obtained precipitate is washed, filtered and dried to obtain a doped nickel-cobalt-manganese ternary precursor;

[0034] S3, uniformly ...

Embodiment 3

[0037] S1, make nickel sulfate 11.62Kg, cobalt sulfate 4.48Kg, manganese sulfate 2.38Kg according to Ni:Mn:Co molar ratio 6:2:2 to prepare 2mol / L sulfate solution, take aluminum nitrate 0.063Kg to dissolve and add the above-mentioned salt Mixed salt solution A is formed in the solution; the concentration of sodium hydroxide and ammonia water is respectively prepared as mixed alkali solution B of 3.0mol / L and 0.45mol / L;

[0038] S2, the prepared mixed salt solution A and mixed alkali solution B are pumped into the reaction kettle at the same time, the flow of alkali solution B is controlled so that the pH of the mixed reaction solution in the reaction kettle is 11.2±0.2, and the stirring speed of the mixed solution in the reaction kettle is 400 rpm, the reaction temperature is 55°C, after the co-precipitation reaction is completed, the obtained precipitate is washed, filtered and dried to obtain a doped nickel-cobalt-manganese ternary precursor;

[0039] S3, uniformly mix the nic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com