Gas-liquid separator for gas treatment

A gas-liquid separator and gas treatment technology, which is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of increased energy consumption, harmful equipment, poor separation effect, etc., and achieve the goal of improving efficiency and enhancing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

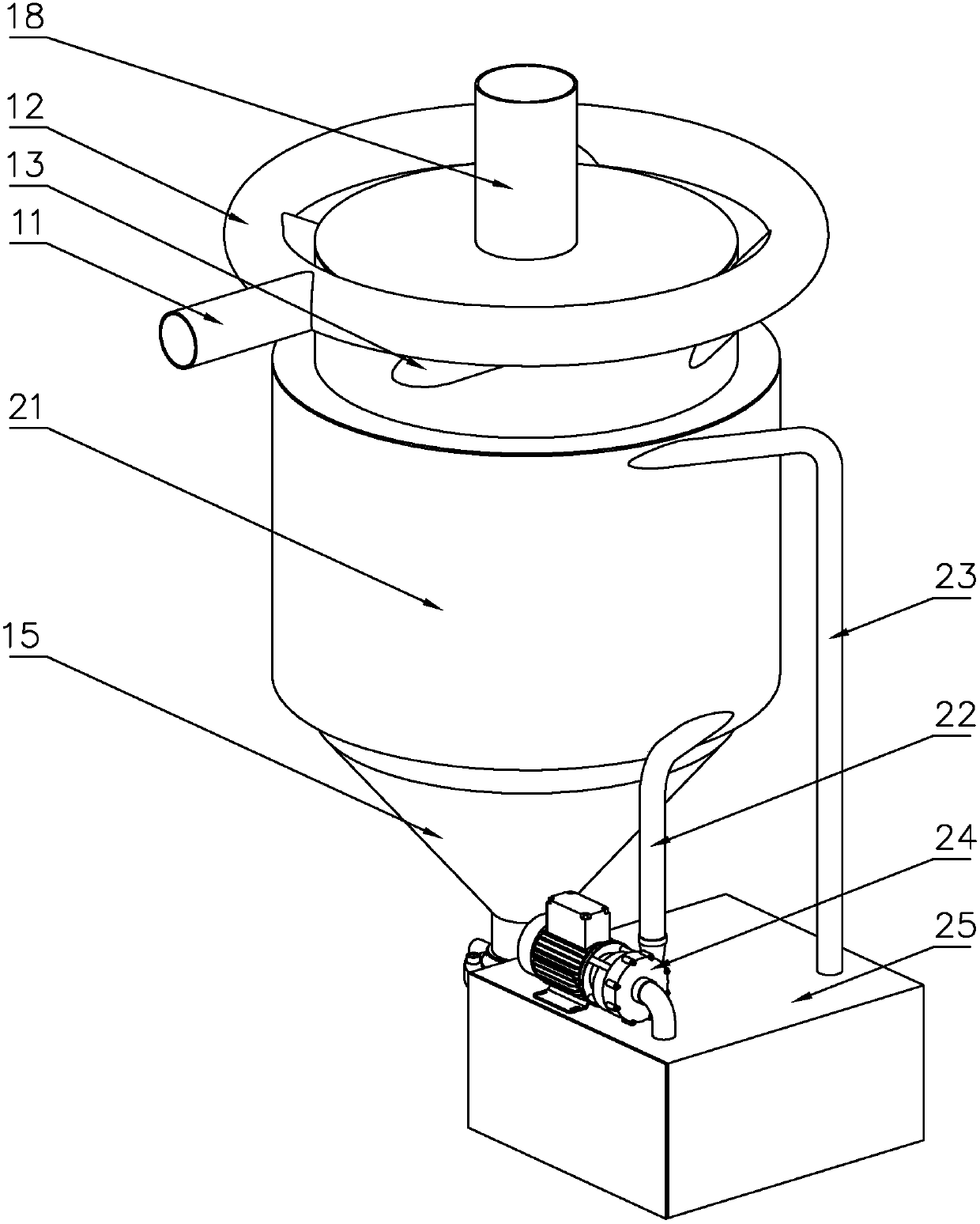

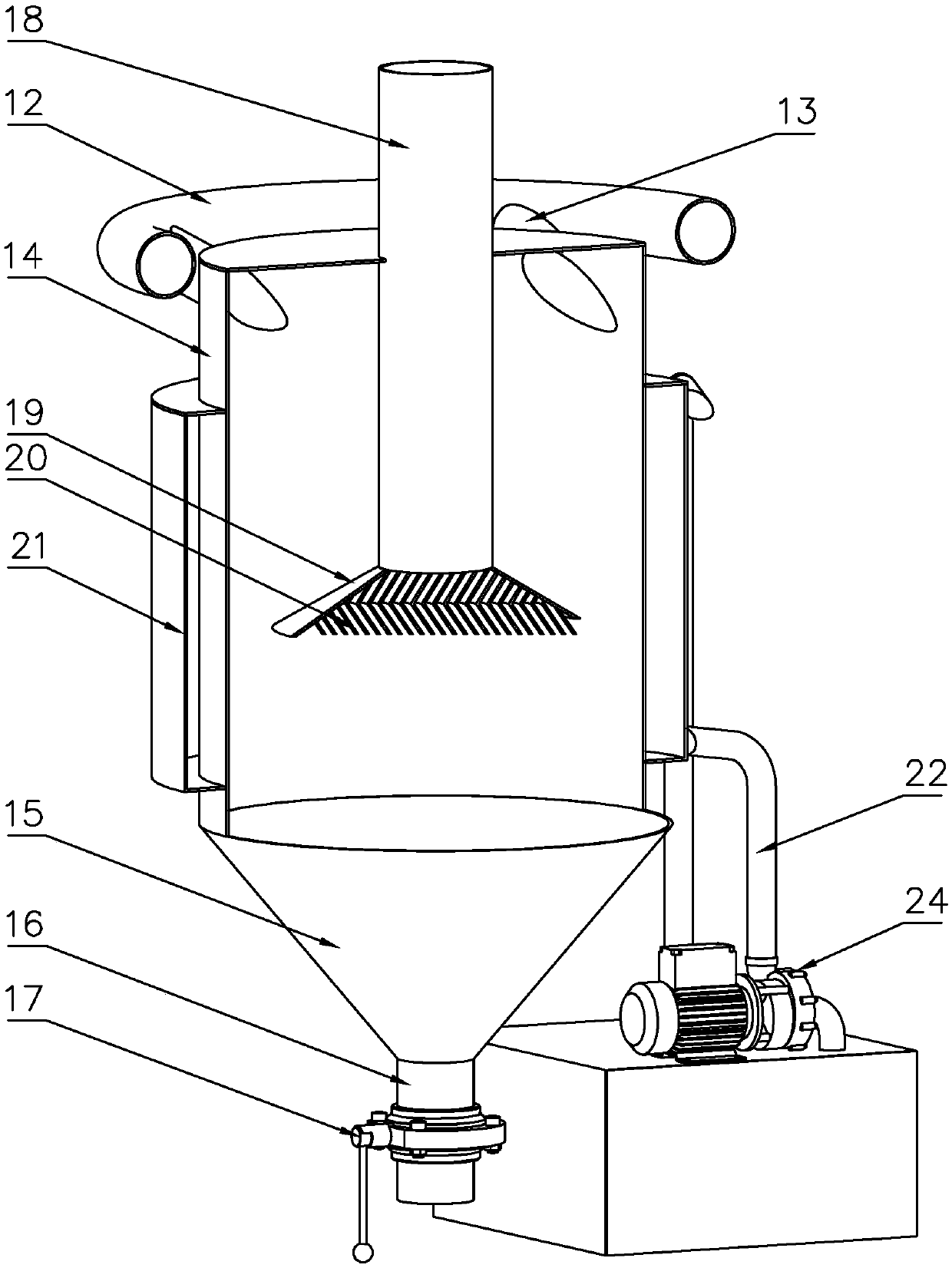

[0015] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-2 , to further specifically describe the technical solution of the present invention.

[0016] A gas-liquid separator for gas treatment, comprising an air inlet main pipe 11, a ring pipe 12, an air inlet branch pipe 13, a cyclone 14, a liquid collecting bucket 15, an air outlet pipe 18, a cooling water tank 21, a circulating water pump 24, and a water storage tank 25 One side of the upper part of the cyclone 14 is provided with some air inlet branches 13, the air inlet branches 13 are obliquely connected to the cyclone 14 at a certain angle, and the inclination angle between the air inlet branches 13 and the cyclone 14 is 5°. °-15°, the inclined air inlet branch pipe 13 speeds up the flow velocity of the mixed gas in the cyclone, and the air intake of multiple groups of air inlet branch pipes 13 has a certain driving effect on the air flow, improving t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com