Micro fluid control equipment used for biochemical detection

A biochemical detection and microfluidic technology, applied in the field of microfluidics, can solve the problems of affecting the detection effect and insufficient contact of the reaction fluid, and achieve the effects of good reproducibility, thorough reaction, and full contact and mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example specifically illustrates the structure of the microfluidic device of the present invention.

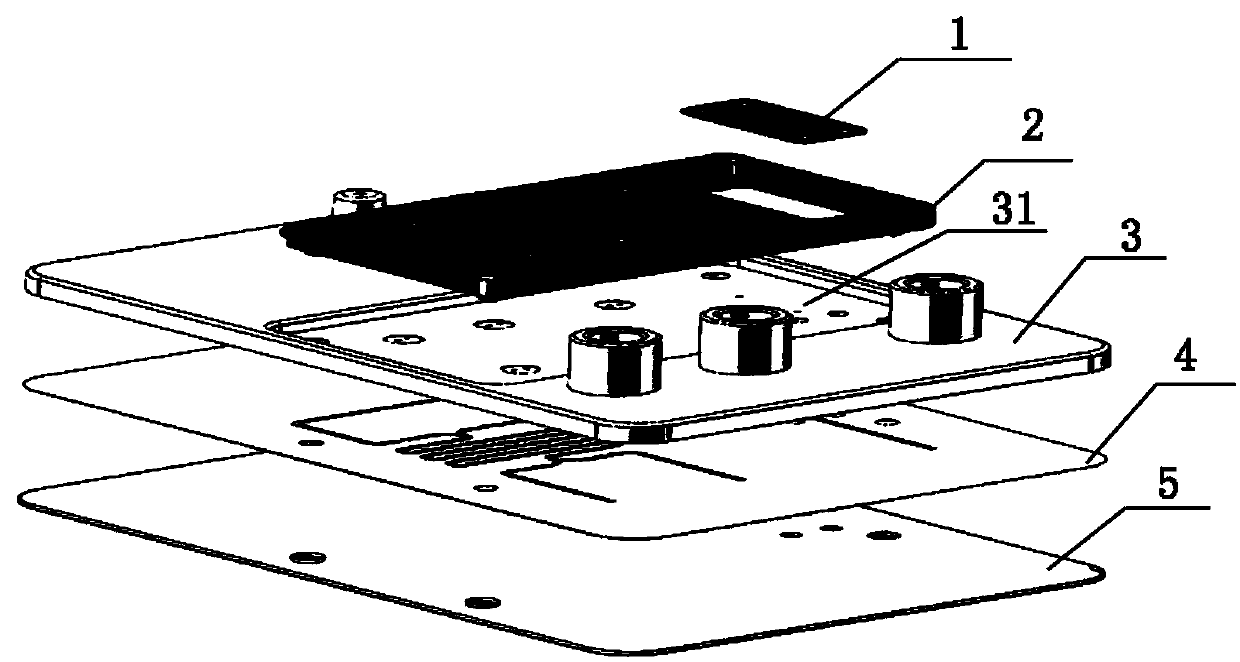

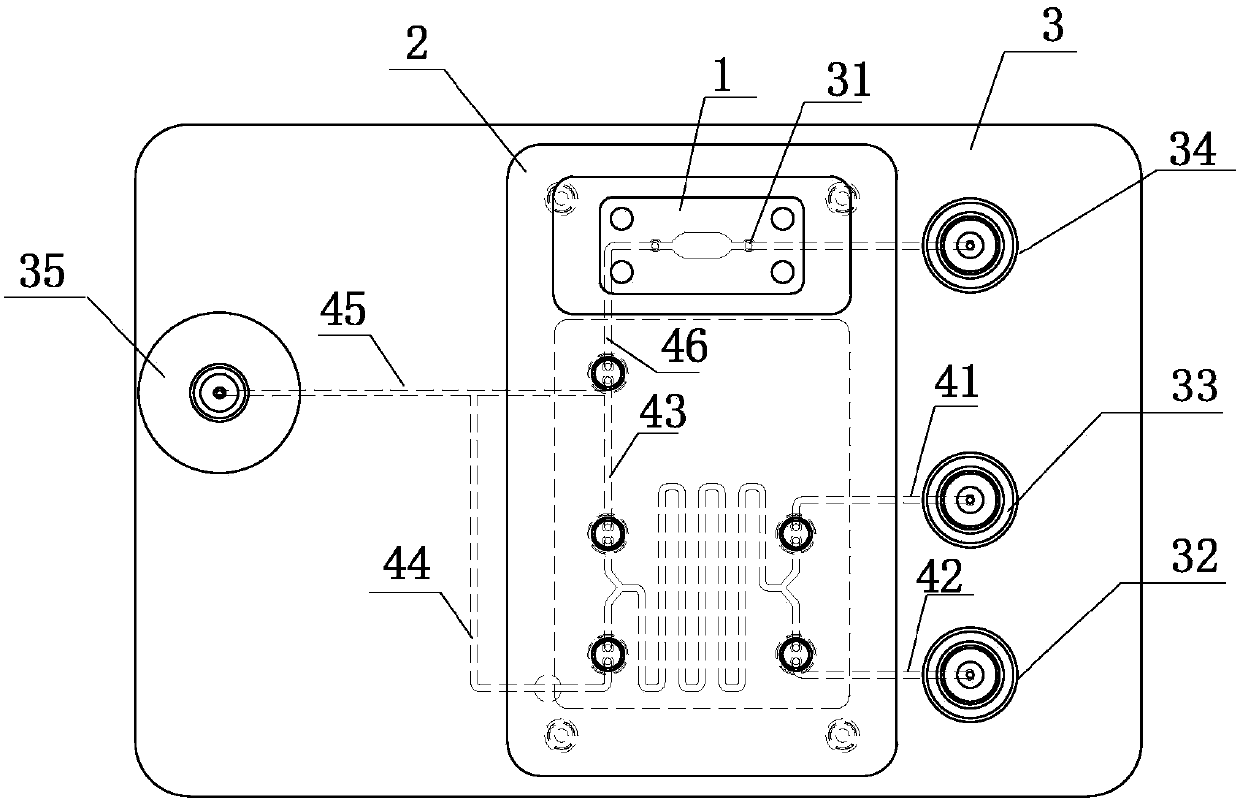

[0032] Such as Figure 1-3 As shown, the microfluidic device of the present invention includes a fluid channel chip and a detection area 1; the fluid channel chip is used for fluid sampling and mixing, and the first micropore 31 is provided on the fluid channel chip; The detection liquid enters the detection area 1 through the first micropore 31 for detection.

[0033] Such as Figure 1-3 As shown, the detection zone structure in this embodiment includes two detection units.

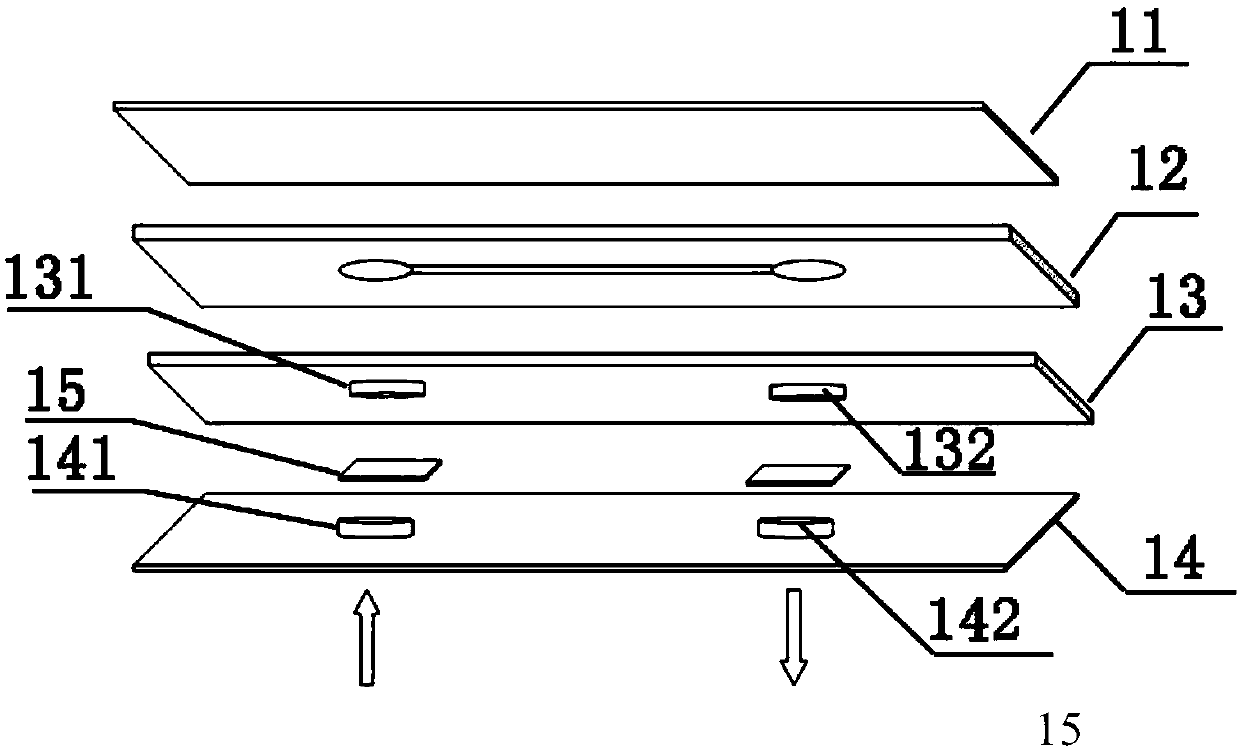

[0034] image 3 It is a schematic diagram of the disassembly of the detection area structure including two detection units, and the detection area structure includes a cover sheet 11, a first substrate 12, a second substrate 13 and a third substrate 14 in order from top to bottom; A substrate 12 is provided with one side of microfluidic channel and the one side bonding of second substrate...

Embodiment 2

[0042] The only difference between this embodiment and Embodiment 1 is that the detection area includes at least 3 detection units, and multiple detection units are connected in series or in parallel.

[0043] Such as Figure 4 as shown, Figure 4 (a) is the detection area structure in series, the mixed fluid to be detected enters the first detection unit through the first micropore, then passes through the second...n-1th detection unit in turn, and finally passes through The micropore of the nth detection unit returns to the fluid channel chip and enters the waste liquid pool to complete the detection;

[0044] Figure 4 (b) is the detection zone structure of the parallel connection of the plurality of detection units, and a micro flow channel is also provided on the lower surface of the third substrate, and after the mixed fluid to be detected passes through the first micropore, it flows on the third substrate. The flow is split on the micro-channel and enters the first n...

Embodiment 3

[0046] This embodiment illustrates the preparation method of the detection zone 1 described in embodiment 1, and the steps are as follows:

[0047] (1) Adopt conventional technology to arrange micro-channels on one side of the first substrate; set micropores on the second substrate and the third substrate;

[0048] (2) Immobilize biomolecules on a large-area membrane, and then cut the large-area membrane into membrane units with biomolecules fixed as biomolecule coatings;

[0049] (3) bonding the cover sheet, the first substrate, the second substrate and the third substrate sequentially from bottom to top, and the biomolecule coating film is fixed between the second substrate and the third substrate in the form of embedding, The assembly is then fixed to the control layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com