Betaine type zwitterionic polymer oil displacement agent and synthetic method thereof

A betaine and copolymer technology, which is applied in the field of betaine-type zwitterionic polymer oil displacement agent and synthesis, can solve the problems of poor temperature resistance and shear resistance, and achieves improved oil recovery, strong hydrophobicity, improved sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Synthesis of polymer oil displacement agent AM / AA / MDPS / NAPA

[0033] The synthetic method of polymer oil displacement agent AM / AA / MDPS / NAPA is as follows:

[0034] (1) Add 80 parts of AM, 18 parts of AA, 1 part of MDPS, 0.3 parts of NAPA and an appropriate amount of emulsifier into the three-necked flask, and stir in 0.5 mol / L sodium chloride solution until the monomers are completely dissolve;

[0035] (2) Adjust the pH of the solution to 7 with 1.0 part of NaOH, put it in 50 o C water bath constant temperature;

[0036] (3) Add 0.5 part of initiator AIBA to the solution, then pass nitrogen gas for 10 min, o C water bath constant temperature sealing reaction for 2 to 5 hours until the copolymerization reaction is completed;

[0037] (4) Precipitate the obtained polymer gel with absolute ethanol, wash, pulverize, and dry to obtain the white powdery polymer AM / AA / MDPS / NAPA.

Embodiment 2

[0038] Example 2 Structural characterization of polymer oil displacement agent AM / AA / MDPS / NAPA

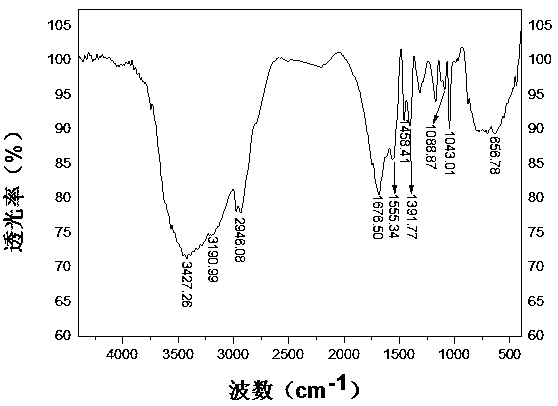

[0039] The sample prepared by the test example in embodiment 1 is carried out structure analysis by infrared spectrogram, adopts KBr tablet method, by WQF-510A Fourier transform infrared spectrometer, the polymer oil displacement agent structure is characterized, and infrared spectrogram is as follows figure 1 shown. from figure 1 It can be seen: 3427.26 cm -1 It is the stretching vibration absorption peak of -OH; 3190.99 cm -1 for-NH 2 stretching vibration absorption peak; 2946.08 cm-1 is -CH 2- Stretching vibration absorption peak of C-H in middle; 1676.50 cm -1 、1555.34 cm -1 C=O stretching vibration absorption peak; 1458.41 cm -1 , 1391.77 cm -1 for CH 3 The bending vibration absorption peak of C-H in middle; 1088.87 cm -1 、1043.01cm -1 for-OSO 2 Stretching vibration absorption peak of S=O in middle; 656.78 cm -1 It is the bending vibration absorption peak of N—H i...

Embodiment 3

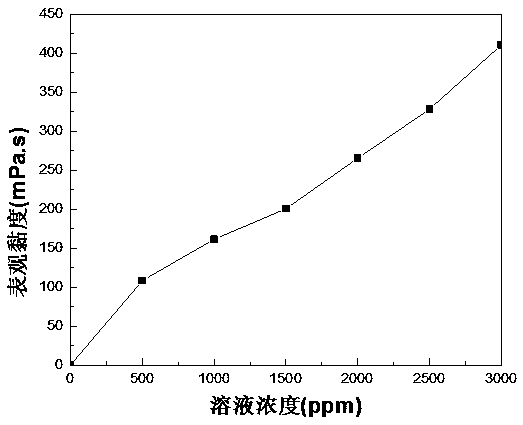

[0040] Example 3 Viscosity investigation of polymer oil displacement agent AM / AA / MDPS / NAPA

[0041] The polymer prepared by the test example in embodiment 1 is mixed with the aqueous solution of different concentration, uses Brookfield DV-Ⅲ+Pro viscometer (00 # or 62 # rotor), at a temperature of 20 o Under the condition of C, measure the apparent viscosity change situation of polymer, data such as figure 2 shown. It can be found from the figure that as the concentration of the polymer solution increases, the apparent viscosity increases greatly, which may be due to the attraction between the polymer molecular chains after the solution reaches a certain concentration, which strengthens the cohesion point between the chain segments, resulting in The hydrodynamic volume of the solution increases, and the apparent viscosity increases effectively. When the concentration reaches 3000 mg / L, the apparent viscosity of the polymer solution can reach 410.7 mPa·s. The results show ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com