Method for recovering multiple components through dilute ethylene

A technology of diluting ethylene and ethylene, which is applied in the production of liquid hydrocarbon mixtures, petroleum industry, gas fuels, etc., can solve the problems of environmental pollution and waste of ethylene resources, and achieve the effect of reducing load and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

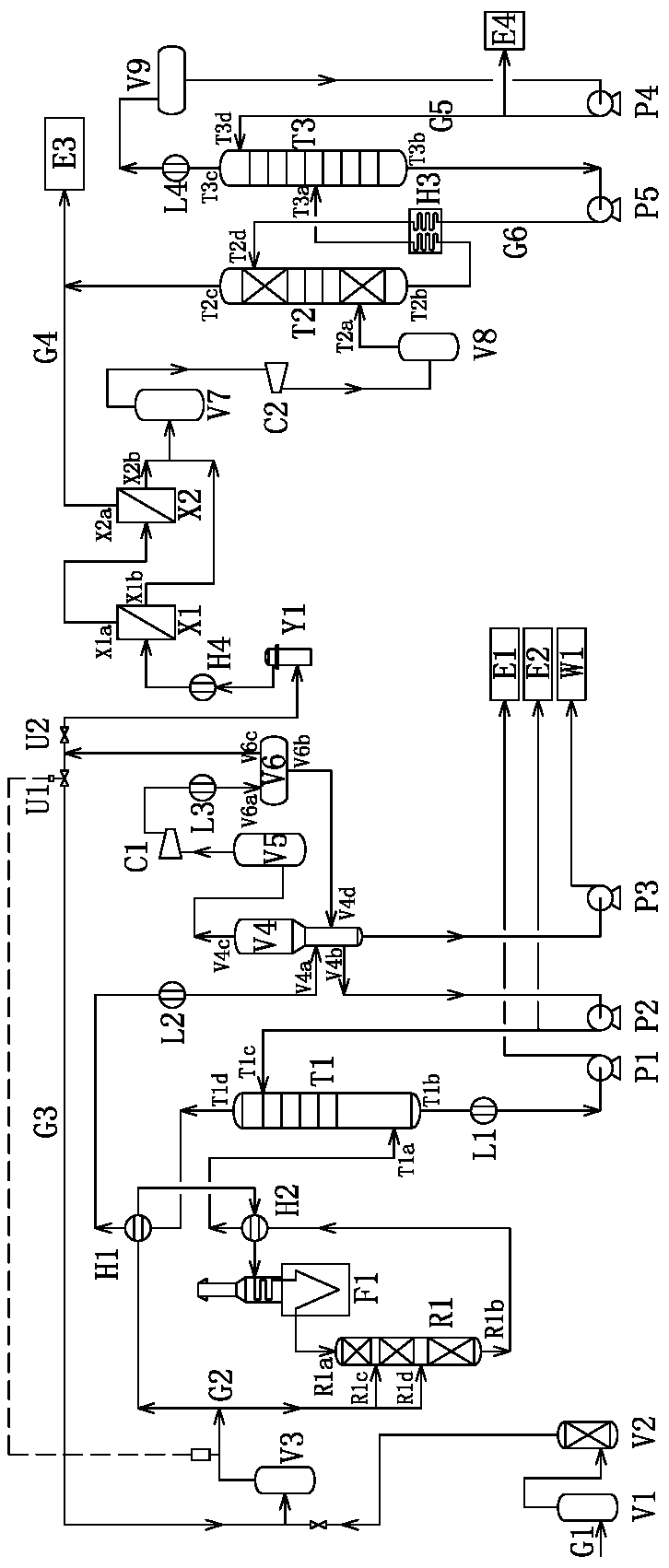

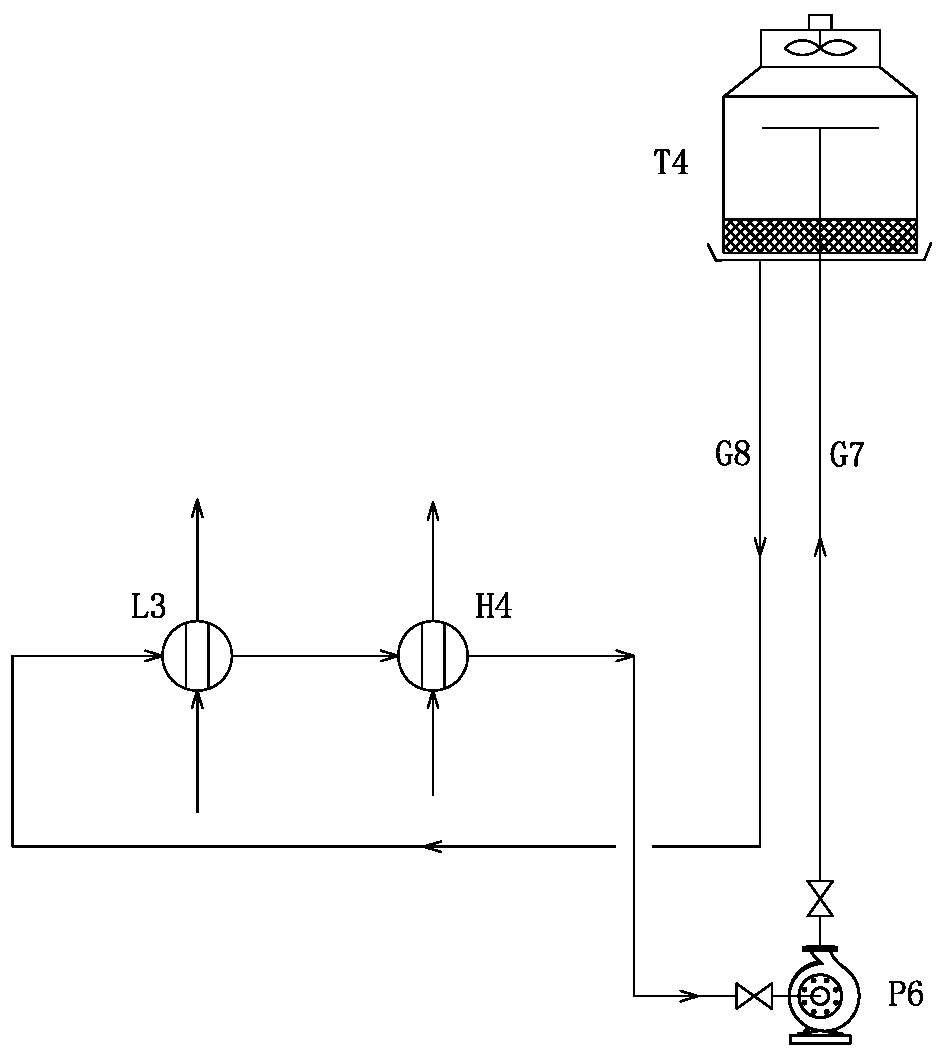

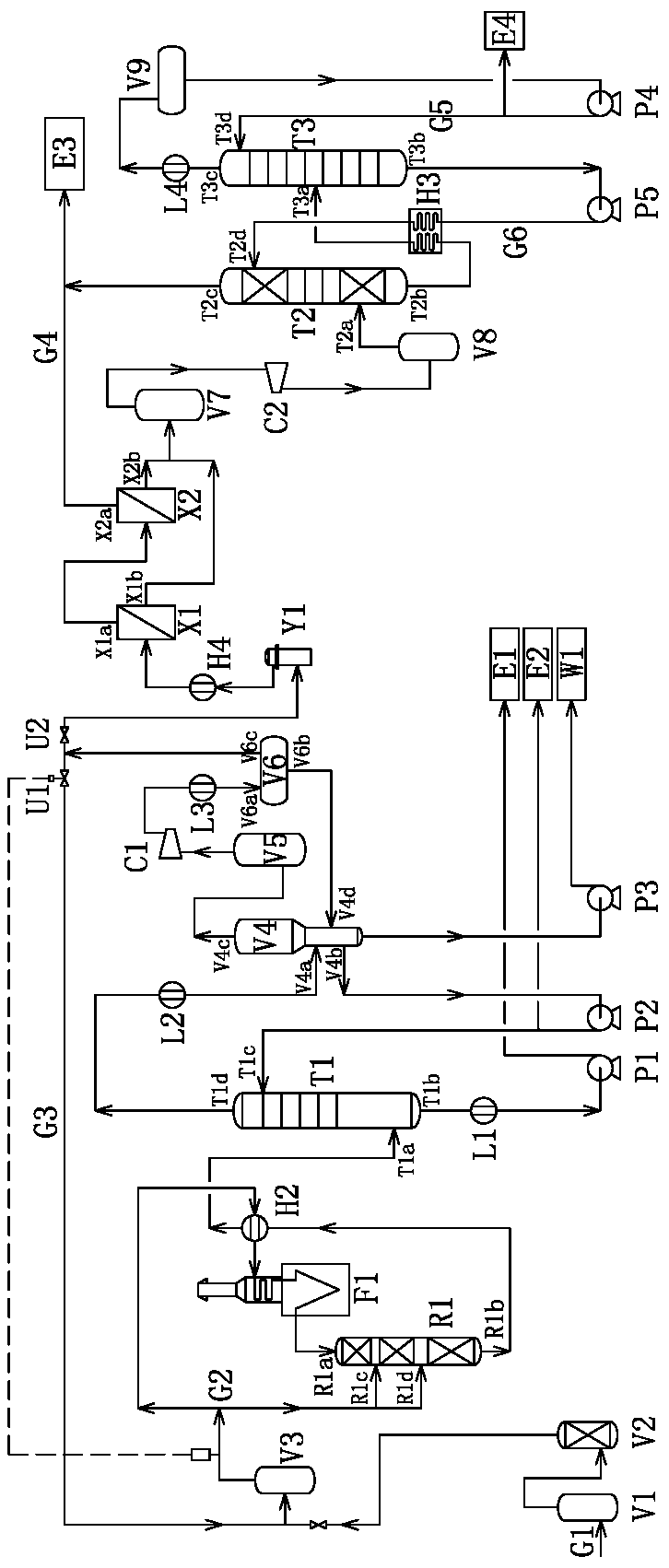

[0022] Such as figure 1 As shown, the system adopted by the present invention to recover multiple components from dilute ethylene includes a catalytic cracking dry gas pipe G1 connected to the outlet of the catalytic cracking dry gas, the outlet of the catalytic cracking dry gas pipe G1 is connected to the inlet of the water washing tank V1, and the water washing tank The outlet of V1 is connected to the inlet of amine liquid adsorber V2, the outlet of amine liquid adsorber V2 is connected to the inlet of raw material buffer tank V3, the outlet of raw material buffer tank V3 is connected to the cold-dry gas tee pipe G2, and the cold-dry gas tee The upper port of the pipe G2 is connected to the cold side inlet of the first heat exchanger H1, the cold side outlet of the first heat exchanger H1 is connected to the cold side inlet of the second heat exchanger H2, and the cold side of the second heat exchanger H2 The outlet is connected to the inlet of the raw material heating furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com