Preparation method of room temperature ferromagnetic hydrogen and hafnium co-doped indium oxide film

A room temperature ferromagnetic and co-doping technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to achieve the effects of good uniformity, easy control of the preparation process, and dense film grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Put the monocrystalline silicon substrate into deionized water, add detergent containing sodium alkylbenzene sulfonate, bathe in water at 80°C for more than 1 hour, wait until the temperature is lower than 40°C, ultrasonicate for more than 15 minutes, and then rinse with deionized water until If there is no foam, add appropriate amount of alcohol, ultrasonic for more than 15 minutes, then rinse with deionized water for more than 5 times, add appropriate amount of deionized water, and ultrasonic for more than 15 minutes.

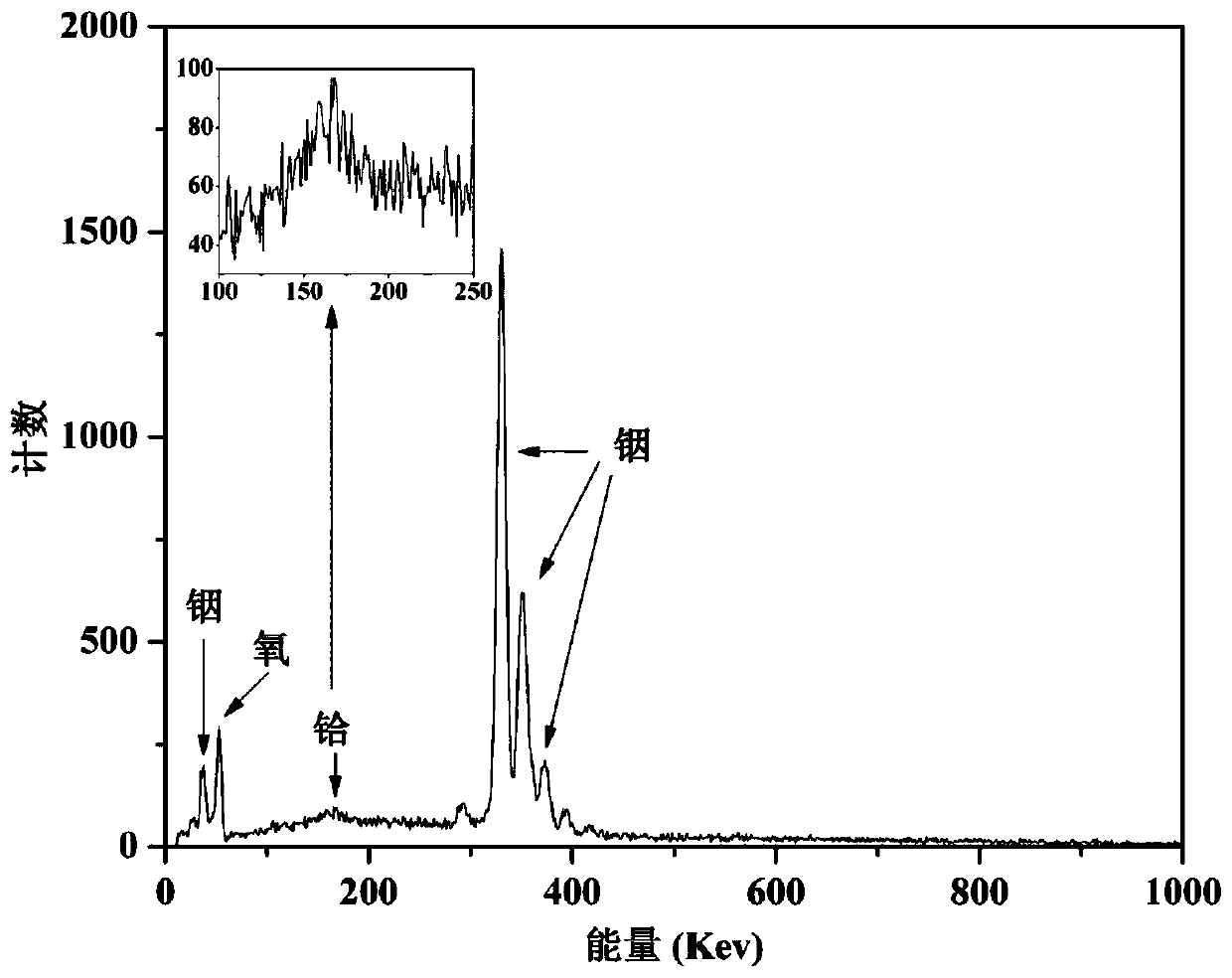

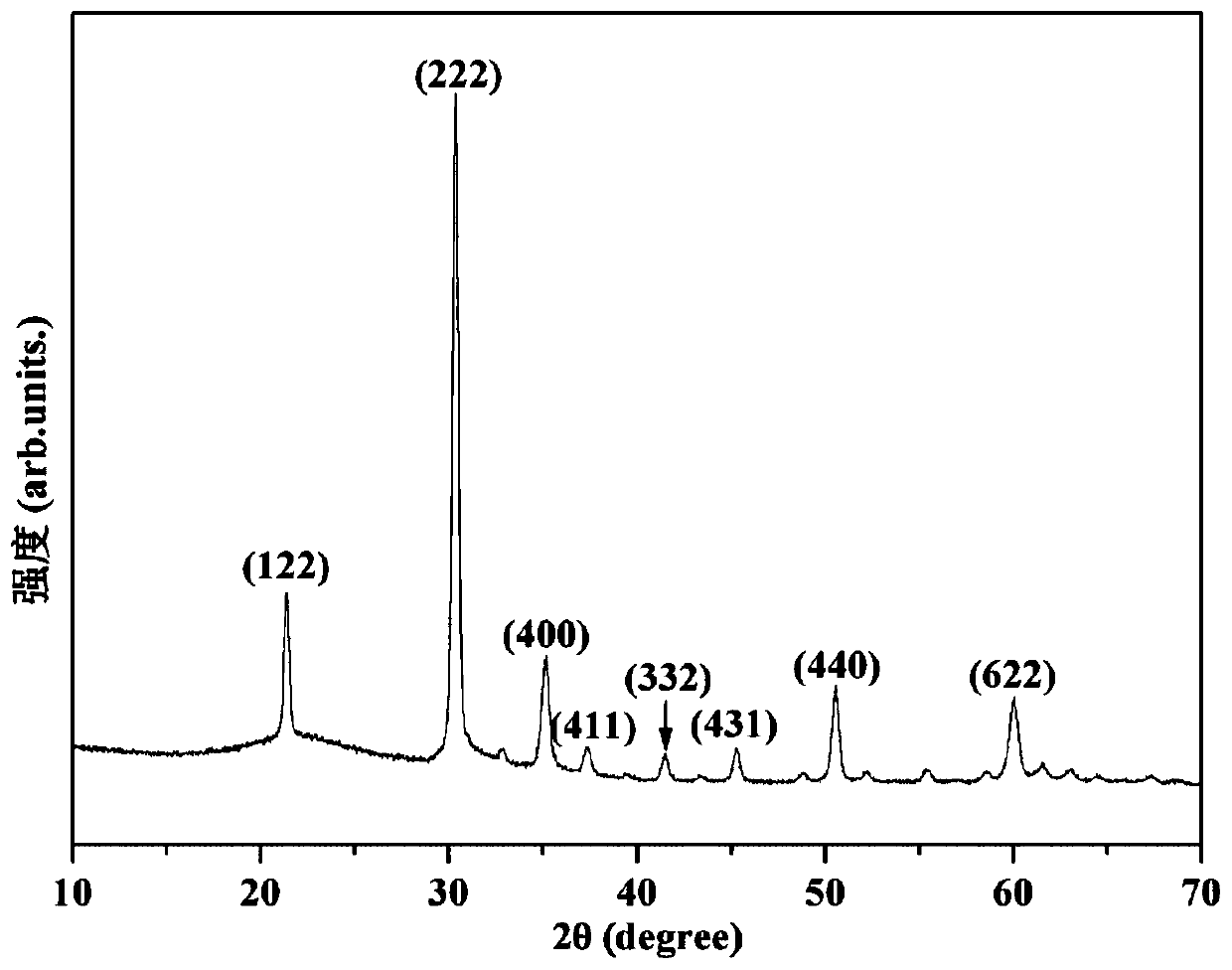

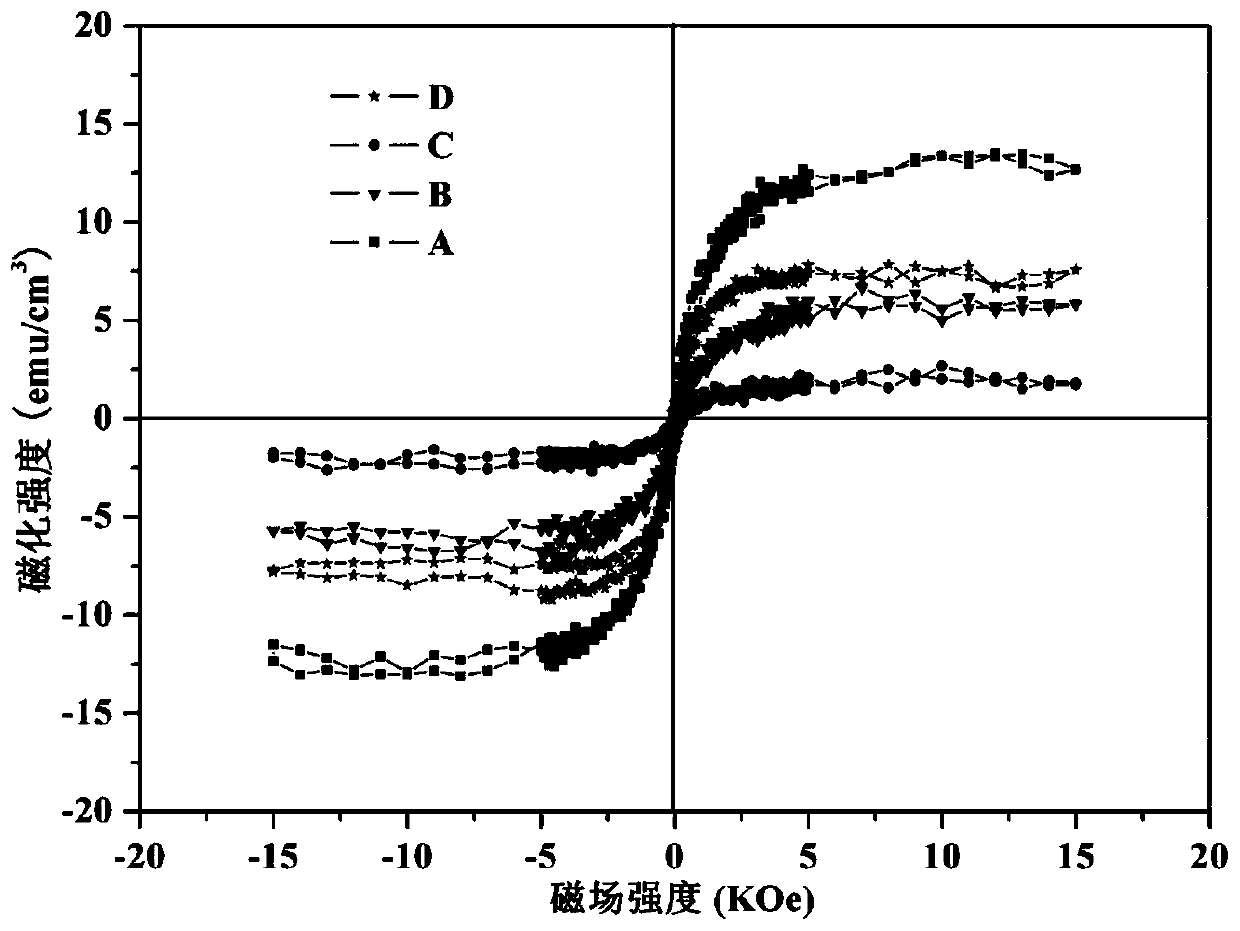

[0020] Put the cleaned substrate into the chamber of the DC magnetron sputtering device, and evacuate to less than 10 -3 Pa, the heating substrate temperature is 250°C, the holding time is more than 30min, Ar gas is introduced, the argon partial pressure is 1.2Pa, hydrogen gas is introduced, the hydrogen partial pressure is 0.08Pa, and the sputtering power density is 5W / cm 2 , prepare the IHFO film, wait for the substrate temperature to cool down to ro...

Embodiment 2

[0023] Put the monocrystalline silicon substrate into deionized water, add detergent containing sodium alkylbenzene sulfonate, bathe in water at 80°C for more than 1 hour, wait until the temperature is lower than 40°C, ultrasonicate for more than 15 minutes, and then rinse with deionized water until If there is no foam, add appropriate amount of alcohol, ultrasonic for more than 15 minutes, then rinse with deionized water for more than 5 times, add appropriate amount of deionized water, and ultrasonic for more than 15 minutes.

[0024] Put the cleaned substrate into the chamber of the DC magnetron sputtering device, and evacuate to less than 10 -3 Pa, the heating substrate temperature is 500°C, the holding time is more than 30min, Ar gas is introduced, the partial pressure is 1.9Pa, hydrogen gas is introduced, the partial pressure is 0.125Pa, and the sputtering power density is 1.5W / cm 2 , prepare the IHFO film, wait for the substrate temperature to cool down to room temperatu...

Embodiment 3

[0027] Put the monocrystalline silicon substrate into deionized water, add detergent containing sodium alkylbenzene sulfonate, bathe in water at 80°C for more than 1 hour, wait until the temperature is lower than 40°C, ultrasonicate for more than 15 minutes, and then rinse with deionized water until If there is no foam, add appropriate amount of alcohol, ultrasonic for more than 15 minutes, then rinse with deionized water for more than 5 times, add appropriate amount of deionized water, and ultrasonic for more than 15 minutes again.

[0028] Put the cleaned substrate into the chamber of the DC magnetron sputtering device, and evacuate until the vacuum degree is lower than 10 -3 Pa, the substrate temperature is 160°C, Ar gas is fed, argon partial pressure is 0.4Pa, hydrogen gas is fed, hydrogen partial pressure is 2.5×10 -2 Pa, sputtering power density is 3W / cm 2 , prepare the IHFO film, wait for the substrate temperature to cool down to room temperature naturally, and take ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com